Patch Cables Go the (Shorter) Distance

Adding a patch cable, patch cord, or jumper solution gives designers greater flexibility in system design.

Patch cables are relatively simple connectivity devices: They consist of a length of cable that connects two optical or electronic devices and transmits signals through a physical conduit. In applications including data centers, industrial systems, and healthcare equipment, physical connections provide an added layer of reliability compared to wireless transmissions. Patch cables — are alternately known as jumpers, patch leads, and patch cords — come in lengths as short as 3” (8cm) and as long as 20’ (6m).

“We use the term ‘patch’ for modern cabling scenarios and cable types, including optical cable. But it’s an old concept from early telephony and radio applications,” said Doug Gilbey, marketing director, e-commerce project manager, and front-end developer, Concord Electronics. “Patch cables were used to bring extra equipment in to substitute for failed devices or to expand networks by adding in new devices. Early patch cords could also be used to create temporary atypical connections between devices for unusual needs.”

Today, patch cables are made from coaxial, optical, shielded twisted-pair (STP), and unshielded twisted-pair (UTP) cables. Each end of the cable terminates in a connector and typically an RJ45 or BNC connector. Patch cables that feature identical connectors on each end are typically considered straight-through connections. These cables adhere to the ANSI/TIA/EIA T-568A wiring standard and are commonly used to connect a computing device to switches, hubs, or routers. Each connector pin in this type of patch cable follows a single wire to an identical pin within the connector on the other end of the cable. Patch cables with different connectors on each end follow the T-568B wiring standard, which governs wires that cross between connectors, and are typically used to connect devices in the same product category (e.g., two computers or two routers).

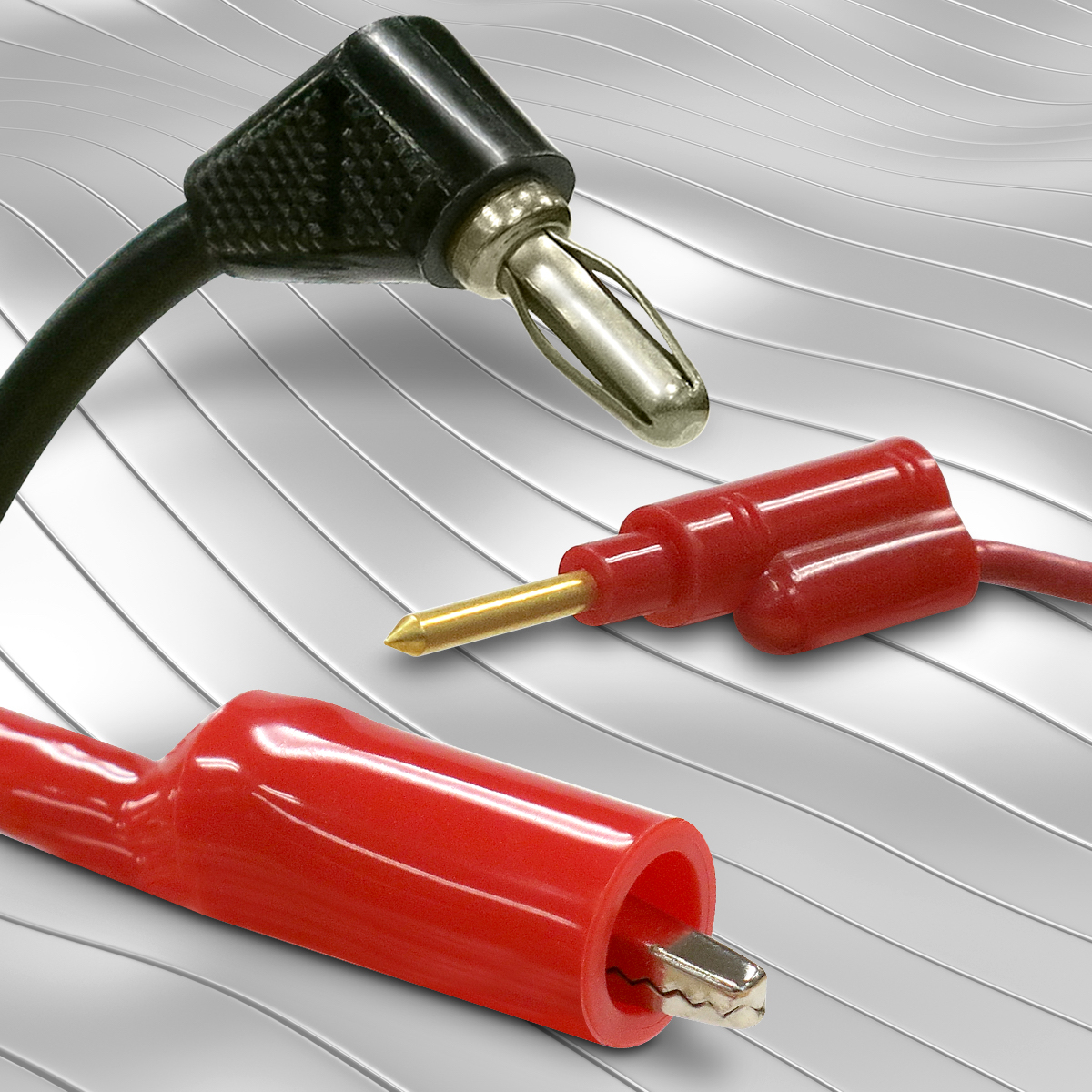

Concord’s Safety Hook 2.5” features a spring-loaded gold-plated beryllium copper contact surrounded by polycarbonate hook insulation to ensure product safety.

Patch cables bear the brunt of pressure, movement, and manipulation around angles and tight spaces as they are installed. To accommodate these usage conditions, Gilbey says that patch cable products are often designed with ruggedized features to better withstand rougher handling than typical cable assemblies experience. “Concord’s patch cord product assemblies are stranded for flexibility, whereas our standard cable is composed of solid copper wire. Our products offer increased flexibility and can withstand additional bending compared to rigid solid conductors that can fail when flexed too many times.”

Offices and Data Centers

Patch cables have a long history of use in office environments, where they’re used to connect computing equipment within networks, such as hubs, routers, and switches. Lightweight, inexpensive UTP patch cords are commonly selected for such environments. STP cords are better suited for environments with a large number of devices, as they include an extra layer of shielding to reduce electromagnetic interference (EMI).

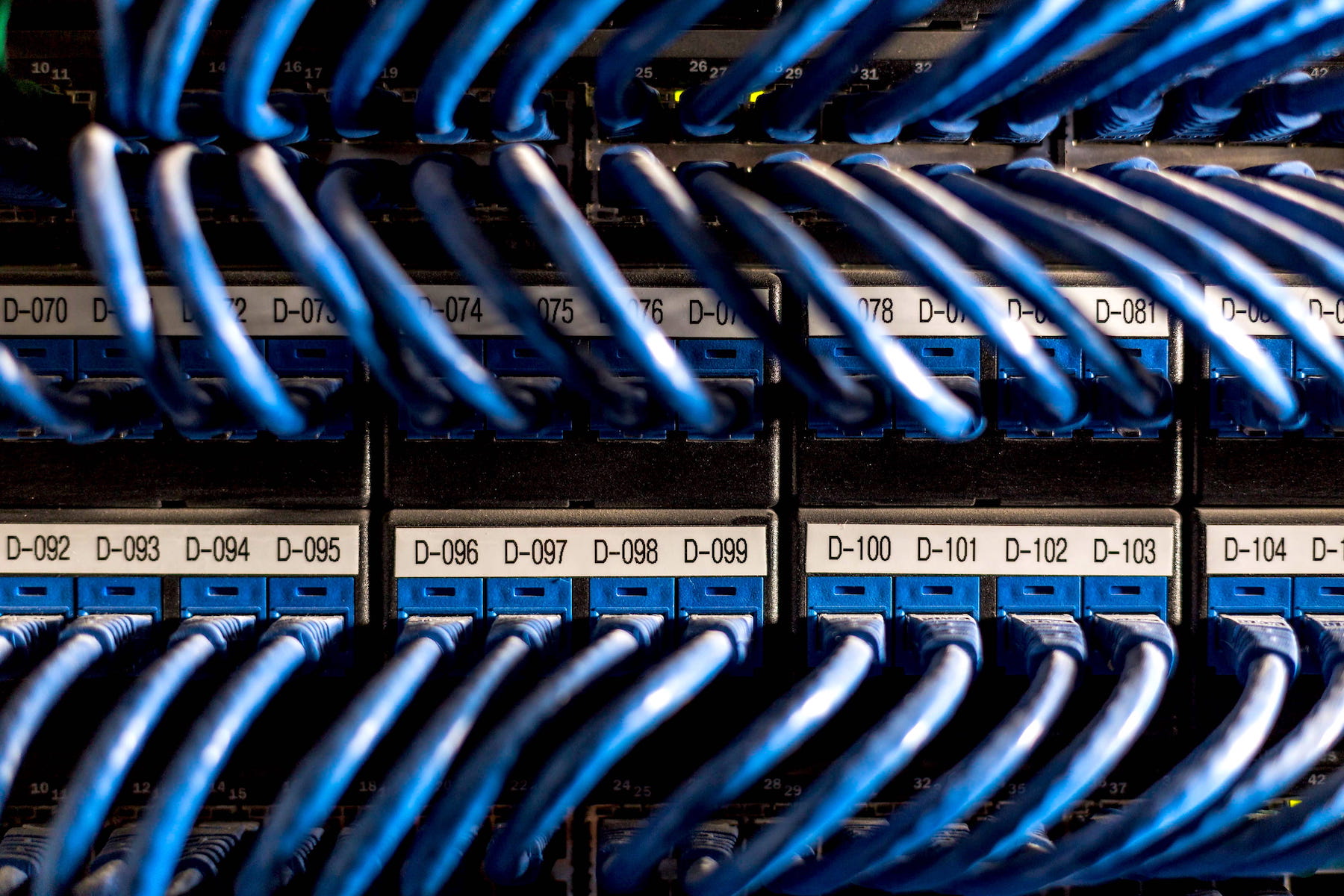

In data center installations, patch cords must be able to handle very heavy data transmission. These patch cords are primarily used to connect equipment in racks, play a critical role in network performance, and employ a combination of optical and copper cables. While optical cable handles high-speed transmission well, the fibers are prone to breakage when bent to fit in tight configurations. Copper is more resilient but is also prone to EMI and signal leakage. So, hybrid cables offer an optimal solution that addresses the shortcomings of each.

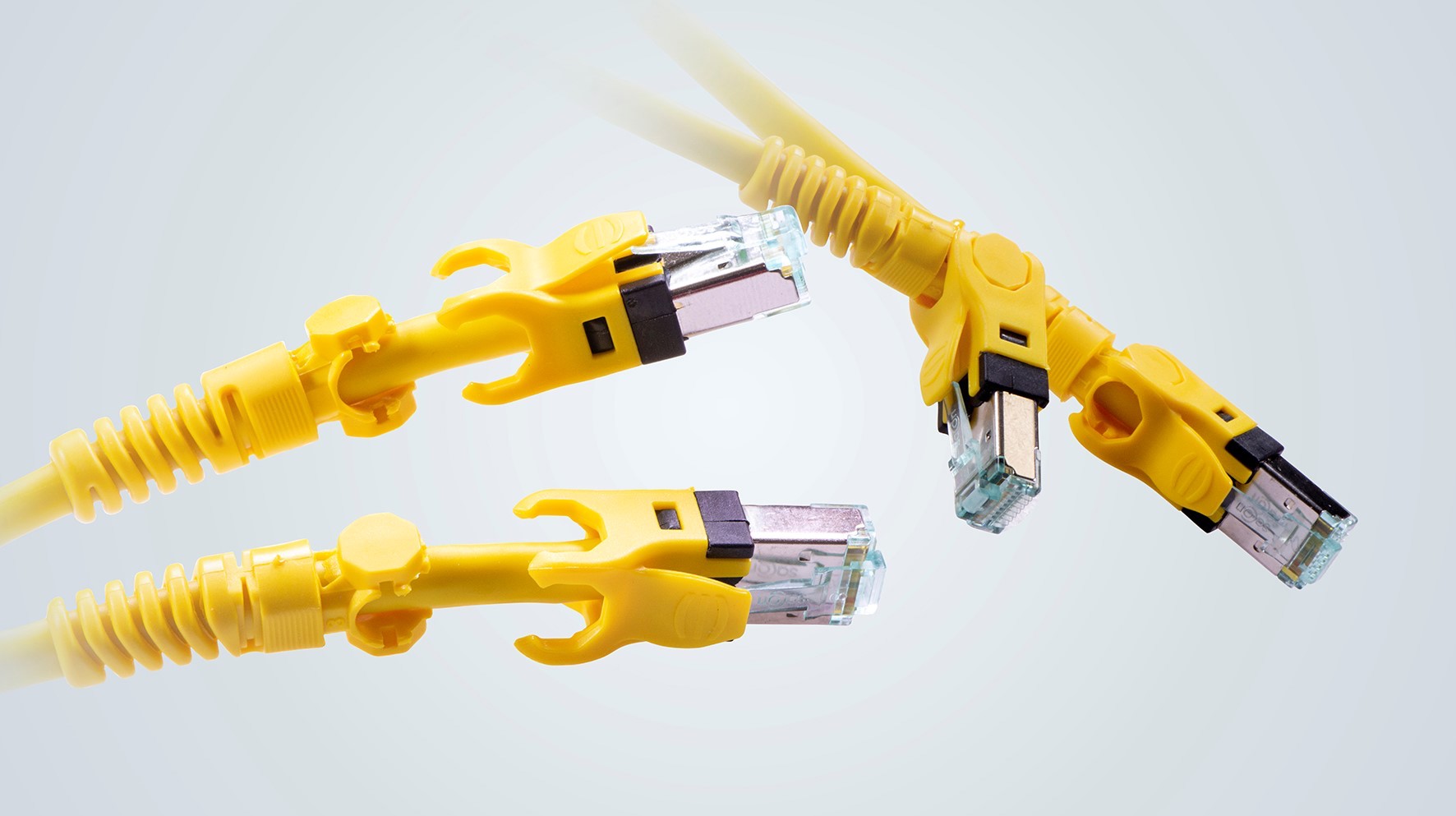

METZ CONNECT’s Ultraflex500 Cat 6 RJ45 Patch Cords (pictured above) are durable, flexible, 26AWG patch cords ideal for use in tight spaces. Their short nozzles facilitate cable bends just over 30mm length, including the plug, and they can be used in data centers, VoIP terminals, cameras, W-LAN hotspots, and other space-constrained data transfer applications. These cables are also suitable for 10GBit Ethernet (IEEE 802.3an), remote powering (e.g., PoE, PoE+, and UPoE), and HDBaseT applications.

METZ CONNECT developed its Ultraflex500 patch cord solutions to address a variety of issues users faced in the field, including installation problems caused by the small bending radius of cables. “In tight industrial cabinets, when switches or other devices are very near the cabinet door, cable bulk can create closing problems,” said METZ CONNECT product manager, Patrick Hirt. “Every Ethernet IP device and compact devices used in Internet of Things applications connect closely or under cramped conditions.”

The trend towards miniaturizing devices, components, and operating environments makes the use of patch cables a valuable way to conserve space. “Designers have less space to work with in small device housings. It is difficult to connect a plug into a RJ45 socket,” said Hirt. “There is also less space for device placement in device-rich environments, such as Wi-Fi Access Points, CCTV/IP cameras, multimedia devices, and telephone and conference phone setups.”

Demand for space-saving yet powerful solutions is especially critical in data centers “where you have a high package density, ports next to each other, and the rack door is close to the panels,” Hirt said. Patch cords are a maneuverable extension that helps manage bulky cabling.

Harsh Environments

As electronic technologies see a dramatic increase in harsh environments, patch cables are being called in to make connections that must withstand the elements and rough use. These cords might be used in heavy equipment, Industry 4.0 applications, or outdoor installations.

Siemon Ruggedized LC Fiber duplex multimode and single-mode LC fiber connectors feature IP66/IP67-rated sealing.

Siemon offers ruggedized copper and fiber patch cords that provide an IP66/IP67-rated seal to protect plug and outlet contacts from dust, moisture, industrial cleaning chemicals, and vibration. Chemical-resistant thermoplastic cables and housings, combined with quarter-turn bayonet-style mating interfaces, also help ensure a tight seal. These cable and connectivity solutions are commonly used in laboratories, hospitals, food processing plants, and other harsh environments.

HARTING’s VarioBoot RJ45 overmolded patch cords feature flexible connector housings that facilitate adjustable orientations and sharp angles in tight cabinet and device configurations without interference or transmission loss. These patch cords can be utilized in high-bandwidth applications, and their 10Gb/s transmission performance makes them suitable for Industrial Ethernet and Industry 4.0 environments.

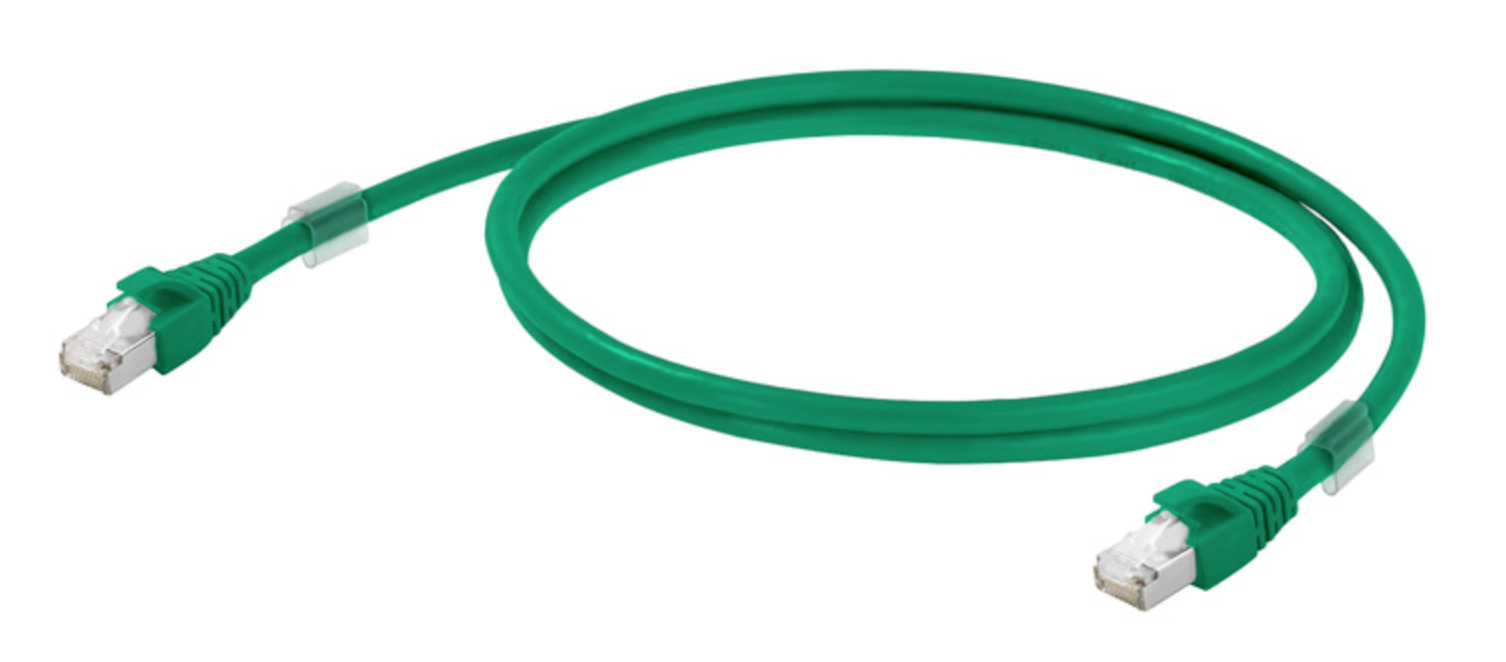

Weidmüeller’s patch cord solutions include options suitable for industrial applications, like the CabinetLine Series. These cables are available in a range of colors, which helps differentiate patch cords in crowded cabling configurations.

Optical Solutions

The build-out of 5G infrastructure and other high-speed applications relies on optical cables to make the connection between small cell antennas and long-distance cables. These cords must handle both high transmission speeds and data volumes and endure rugged conditions. They can include a variety of connectors but most commonly employ LC, ST, SC, MPO, or SC connectors.

In order to manage the bending that occurs in tight installations, optical patch cords are constructed with bend-insensitive fibers or hybrid copper-fiber configurations. The cable jacketing is typically available in three coatings: polyvinyl chloride (PVC), low-smoke/zero- halogen (LSZH), and optical fiber nonconductive plenum (OFNP). Selection depends on where the cable will be installed within a building or network installation. A fourth option, armored cable, is used in areas where a cable is subject to being stepped on or driven over. Because of the more delicate nature of optical cable, protection is an important specification consideration. In addition, optical jumpers give designers more flexibility by allowing a greater degree of protection to be applied in areas that will experience the most stress and less expensive cabling to be used for the bulk of the installation.

Like this article? Check out our other data center, networking, and harsh environment articles, our Datacom/Telecom and Wire/Cable Market Pages, and our 2020 and 2019 Article Archives.

- Meet the Connector: DIN Standard Connectors - April 16, 2024

- Software-Driven Radio Reinvigorates Old Technology - April 9, 2024

- What is a Busbar? - April 2, 2024