Advances in Optical Connectivity

The ever-increasing demand for greater bandwidth, data density, and reach using less energy has resulted in several new technologies that favor fiber optical channels.

Engineers have long recognized the performance advantages of replacing electrical signals with pulses of light. Increased bandwidth capacity and reach, coupled with reduced cable bulk and immunity from external noise, are attributes of fiber that support the demands of applications in data centers and telecommunication networks. Broad implementation of fiber across these industries has been slowed by the space and power hungry electro-optic conversion process, a difficult and time-consuming connector termination procedure, fragile optical fiber as well as the constant improvements of lower cost copper alternatives.

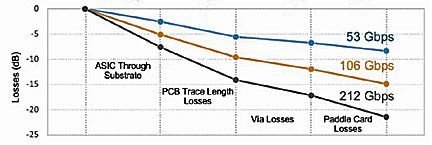

Times have changed and so has the balance of factors that favor one media over the other. As data rates push into the 10+ Gb/s range, copper circuits suffer serious signal integrity issues including attenuation, forward and backward crosstalk, reflections, skew, jitter, and intersymbol interference, all of which increase in severity with length. Bump up the speed to 50+ Gb/s and everything gets worse. The maximum practical length of a 112 Gb/s circuit in a printed circuit board is measured in inches.

A high-speed optical signal conducted through hair-thin fiber delivers signals with much greater fidelity, less bulk, and at much longer distances.

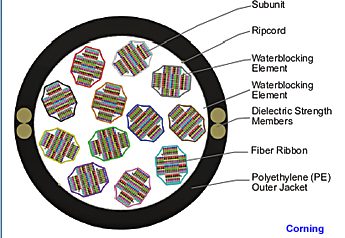

Optical fiber continues to be upgraded in terms of reduced attenuation, tighter bend radius, and overall durability. Advanced fiber construction, such as ribbonized optical fiber, allows automated termination. Bonded stacks of ribbonized fibers can be packaged under a ruggedized external jacket that contains up to 3,455 fibers in a cable that is only 1.1 inch in diameter. New fiber configurations, including multicore, hollow core, liquid core, and polarization-maintaining optical fiber, serve the specific needs of specialized applications.

Optical fiber continues to be upgraded in terms of reduced attenuation, tighter bend radius, and overall durability. Advanced fiber construction, such as ribbonized optical fiber, allows automated termination. Bonded stacks of ribbonized fibers can be packaged under a ruggedized external jacket that contains up to 3,455 fibers in a cable that is only 1.1 inch in diameter. New fiber configurations, including multicore, hollow core, liquid core, and polarization-maintaining optical fiber, serve the specific needs of specialized applications.

The ever-increasing demand for greater bandwidth, data density, and reach using less energy has resulted in several technologies that favor optical channels.

The ever-increasing demand for greater bandwidth, data density, and reach using less energy has resulted in several technologies that favor optical channels.

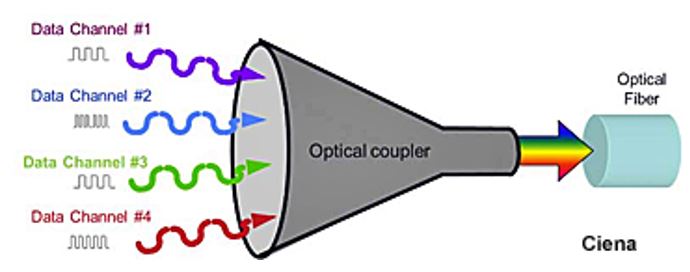

As the adoption of PAM4 modulation and Forward Error Correction (FEC) have enabled 112 Gb/s copper channels, optical data transmission capacity has been increased using wavelength division multiplexing (WDM). This technology enables a single fiber to simultaneously carry several “colors” of light to deliver multiple channels of data.

Even greater efficiency of optical fibers can be achieved using advanced coherent optics. Data transfer rates can be increased by several methods, including increasing the data rate. This strategy transmits more symbols per second, sending lower speed signals over multiple parallel fibers. Another method uses multiple characteristics of a single beam of light to transmit encoded data.

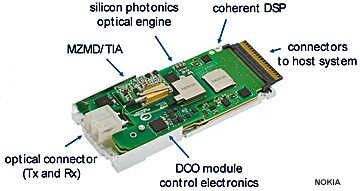

Coherent transmission achieves higher sensitivity and reach than direct amplitude detection while significantly increasing the spectral efficiency by encoding more bits on each symbol using phase, amplitude, and polarization to transport information. Coherent optics have been used in long reach telecom applications for years, but advances in chip integration and packaging are opening shorter reach applications that demand high transfer rates. Emerging applications in artificial intelligence, expanding 5G infrastructure, and the Internet of Things are driving the introduction of pluggable coherent optical transceivers that deliver 400 Gb/s.

Coherent pluggable transceivers are now available in CFP2, QSFP-DD, and OSFP form factors.

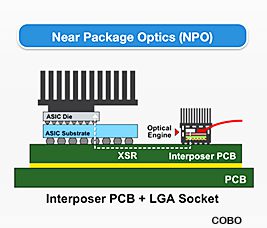

Concerns about the cost and size of the electro-optical conversion process have also been addressed. The PCB real estate and power premiums that traditional optical engines incurred have been reduced by advanced modules that enable “near-package” optics. These tiny devices can be packaged in “chiplets” mounted on the same substrate as an ASIC and are a core element of the emerging co-packaged optics evolution.

Concerns about the cost and size of the electro-optical conversion process have also been addressed. The PCB real estate and power premiums that traditional optical engines incurred have been reduced by advanced modules that enable “near-package” optics. These tiny devices can be packaged in “chiplets” mounted on the same substrate as an ASIC and are a core element of the emerging co-packaged optics evolution.

To support new applications for optical links, connector manufacturers have accelerated the development and introduction of new fiber optic connectors. These innovative interfaces incorporate key features, including simplicity of termination, resistance to end-face contamination, low loss, durability in harsh environments, high fiber count, and density in a reduced connector profile. Traditional copper connector manufacturers such as Amphenol Communications Solutions, Hirose Electric, and Panduit have been expanding their optical connector offerings, while optical component suppliers such as SENKO, Sumitomo, and US Conec, have been actively introducing new optical connectors that address the requirements of evolving applications.

Advanced optical connectors eliminate the laborious preparation, polish, and epoxy process and have been replaced with pre-polished assemblies that greatly simplify the field termination procedure.

Relatively large single-fiber connectors have been supplemented with high-density interfaces that simultaneously terminate up to 64 optical fibers per ferrule. Both single and multi-mode fiber can be terminated with repeatable precision.

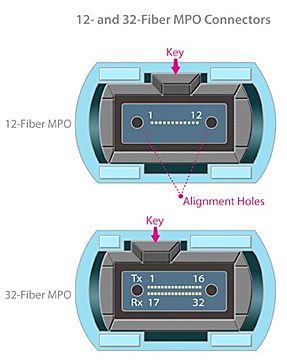

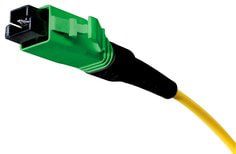

Connectors including the MPO/MTP interfaces have become standards in the datacom and telecom industries and feature the ability to terminate from 12 to 32 fibers.

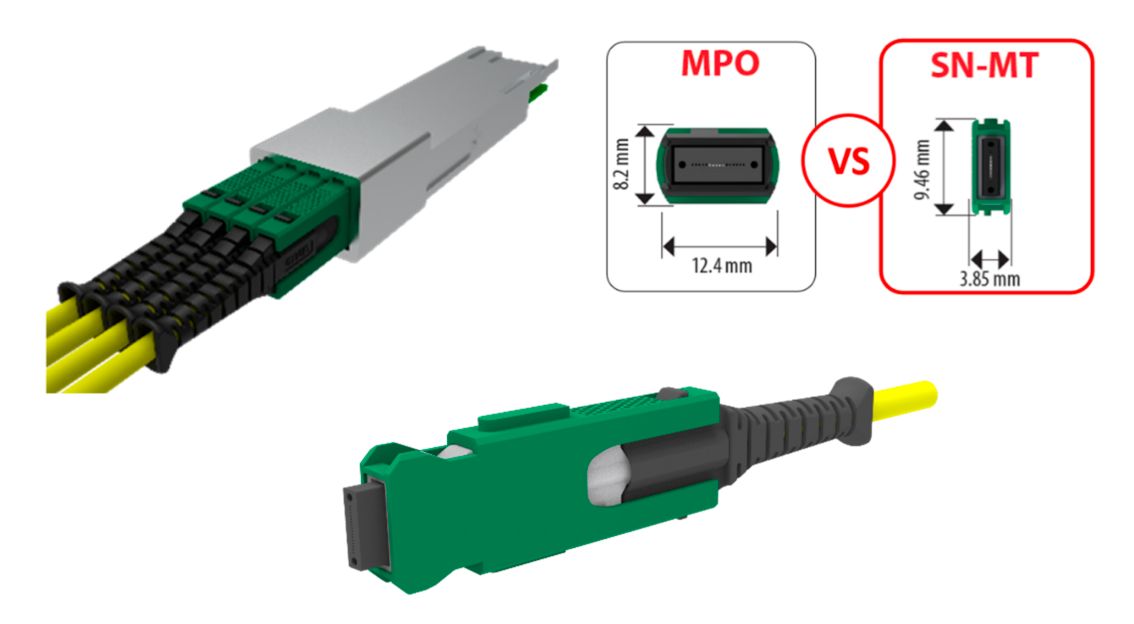

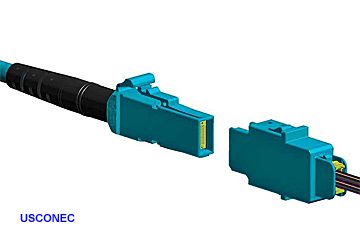

Slimming the profile of the MPO to enable higher fiber density on a panel has resulted in new configurations of push-pull optical connectors from US Conec and SENKO.

The SN-MT connector from SENKO is an 8 and 16 fiber connector that nearly triples the density of an MPO 16 fiber connector. The SN-MT connector from SENKO is an 8 and 16 fiber connector that nearly triples the density of an MPO 16 fiber connector.

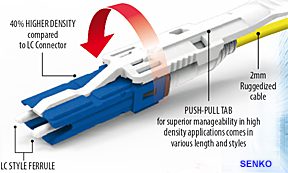

The SENKO CS connector offers a 40% profile reduction when compared to the standard LC duplex connector.

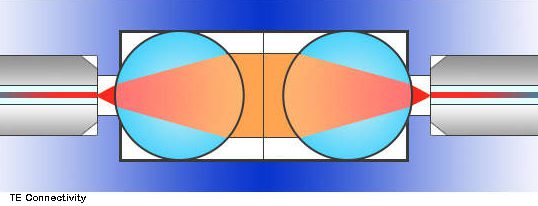

Concern about contamination at the optical interface has been addressed with expanded beam technology that minimizes loss by increasing the diameter of the transmitted beam in the connector, assuring more consistent performance in harsh environments.

Concern about contamination at the optical interface has been addressed with expanded beam technology that minimizes loss by increasing the diameter of the transmitted beam in the connector, assuring more consistent performance in harsh environments.

The SN-MT connector from SENKO is an 8 and 16 fiber connector that nearly triples the density of a MPO 16 fiber connector.

3M collaborated with Rosenberger to develop the HD-Expanded Beam EBO connector which is designed around a unique perpendicular interface. The hermaphroditic design supports single and multimode fiber.

The MXC connector is an example of a high-density optical connector that combines the capacity of terminating up to 64 fibers with expanded beam reliability.

The MXC connector is an example of a high-density optical connector that combines the capacity of terminating up to 64 fibers with expanded beam reliability.

Molex recently announced its External Laser Source Interconnect System (ELSIS) which is a pluggable blind-mate cage and module to enable external laser co-packaged optic architecture.

Additional manufacturers, including such diverse suppliers as Amphenol Communications Solutions, Carlisle Interconnect Technologies, Molex, Broadcom, Sumitomo Electric, Glenair, Swick, Designs, and Legrand, continue to add to the roster of optical interconnects to support next generation products.

See Bob Hult’s Tech Trends series to learn more about the evolution of high-speed interconnects.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for Amphenol Communications Solutions, Carlisle Interconnect Technologies, Hirose Electric, and Molex.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Optics Outpace Copper at OFC 2024 - April 16, 2024

- Digital Lighting Enhances your Theatrical Experience - March 5, 2024

- DesignCon 2024 in Review - February 13, 2024