Seven Deadly Counterfeit Cable Sins

Unscrupulous sellers have found many ways to cut costs on cables, drawing customers in with the low price. L-com shares the “Seven Deadly Counterfeit Cable Sins” and advises how you can avoid them.

What scares you more than a faulty, overrated, counterfeit cable? If you’re like us and work with cables on a daily basis, then you know the answer: Nothing.

What scares you more than a faulty, overrated, counterfeit cable? If you’re like us and work with cables on a daily basis, then you know the answer: Nothing.

Shockingly, unscrupulous sellers have found many ways to cut costs on cables, drawing in customers with the low price. But what they don’t tell you is that it comes at a price – sacrificing safety, performance, and network stability.

So how do you identify them? Counterfeit cables are bulk cables or cable assemblies sold under false pretenses to undercut legitimate manufacturers. Usually this means the cable specification does not match the actual product construction, or it could be that the seller falsely implies that a cable meets a particular performance standard or flammability rating such as Category 5E or CMP/Plenum. If you get a low bid for your next cable quote, check these factors to make sure you get what you pay for.

- Substituting steel or aluminum for pure copper: Copper-clad steel (CCS) or copper-clad aluminum (CCA) are classic methods of saving on costly copper needed to make cables. Over the length of the cable, however, the signal integrity will drop below the noise and cross-talk levels. There’s a good reason the EIA/TIA has not approved CCS or CCA cable for use in high-speed networks.

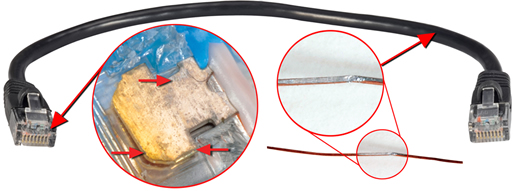

- Deceiving connector construction: This is a two-part deception. For “RJ-45” (8p x 8c) connectors, rejected molded plastic bodies can be re-ground back to pellets, added to new plastic, and then made into new bodies, which can lower the combustion rating for the overall connector. A good tip: Check the connector body for foggy or yellowing plastic. Aside from the body, the metal contacts are first coated with nickel, then with gold, to ensure a good connection. Manufacturers have been skipping the nickel and skimping on the gold, sometimes called gold flash or selective plating. Contacts made this way will eventually corrode and fail to connect when mated.

- Cable jacket material: For those applications that require CMP or CMR flammability rating, the requirement is critical. If it is specified that the cable meets CMP or CMR ratings (per the NEC code) and you get an unusually low bid, ask for proof of the jacket material. A legitimate business will offer a signed Certificate of Conformance (CoC) for the product they sell.

- Selective electrical performance testing: Some manufacturers will claim their cable or cable assemblies were “Fluke-tested,” but won’t clarify that they only ran the channel test, not the full patch testing. Patch testing is difficult to pass and more expensive, but legitimate manufacturers will do it because it ensures the cable conforms to standards and is worth what they are charging.

- Misleading cable markings: All cables sold in the United States provide a UL “e-file number” or the manufacturer’s name and model number so that you can look them up on UL’s database. The problem is that the marking may conform to UL’s standard, but the cable may not. Again, a signed CoC will protect against counterfeits so make sure you get one.

- Wire gauge changes: Often 25 or 26 AWG cables can be mislabeled as 24 AWG. If you require 24 AWG, you should always request a sample cable, cut it open, strip the insulation off of the wires and measure them. If the size is incorrect, don’t trust any other of the manufacturer’s claims; if they are untruthful about the wire gauge, what else could they be hiding?

- The golden sample: While it is a good idea to get a sample up front, many manufacturers will make a “golden sample” to fit your specifications, sometimes at great expense. When it comes time to manufacture the rest, they may scrimp to deliver under cost. You should always set up a system where you QC some of the cables in each shipment – and without the manufacturer’s prior knowledge.

This problem is much more common than you think! L-com found counterfeit cables from both big and small manufacturers, and from both domestic and overseas sources. “Made in the USA” means nothing if the cable is made with poor components in order to offer a cheaper price. If price is your priority, someone can always make a cheaper cable. It doesn’t matter where a cable is made, but how the cable is made.

The key is to know that your seller or manufacturer checks the cable assemblies, can prove UL compliance, tests its cables, and always meets standards.