Ex- and ATEX-Approved Connector Products

This week’s Product Roundup highlights Ex- and ATEX-approved explosion-proof connector products for harsh-environment, hazardous-atmosphere applications including industrial, marine, oil and gas, and alternative energy equipment.

Ex- and ATEX-Approved Connectors

Phoenix Contact offers a range of PCB terminal blocks and PCB connectors with IECEx approval for use in potentially explosive environments, including lighting and building automation applications. Solutions are available with 2–16 contacts on 5.0mm, 5.08mm, and 7.62mm pitches and screw, spring, or push-in connections and are compatible with wave soldering processes. The Ex-approved SPTAF 1 PCB terminal blocks are available in three subseries all designed to offer an optimal combination of space savings and wiring convenience. All three have a low-profile form factor with a user-friendly spring-lever wire termination mechanism and integrated test points, support the quick and easy insertion of solid and ferruled wires without opening the spring connection, and are rated for 8A 300V (UL), and 24–16AWG. The IL Series has an internal lever that keeps the overall connector height to just 8mm for the tightest-fit applications and can be opened with a screwdriver to support stranded-wire connections. The EL Series has an external lever that brings the overall height to 10.2mm but supports manual, tool-less operation. The LL Series has an innovative locking lever that brings the overall height to just shy of 11mm but locks in the open position to allow installers to use both hands for wiring and also supports manual, tool-less operation. In addition, sliced connector designs can be color-coded to make error-free wiring even easier.

TE Connectivity’ s DEUTSCH 9316 Series Connectors are designed to ensure safety and survivability in extremely harsh marine applications with depths up to 7,500m, pressures up to 750 bar (10,875psi), and temperatures up to 190°C, including underwater control systems, submarines, offshore oil platforms and loading buoys, subsea motors and compressors, and wellheads. The rugged, explosion-proof series is Ex- and ATEX-approved, hermetically sealed, and easy to use. It features stainless steel shells in front- and rear-mount circular or square bulkhead receptacle configurations, glass-to-metal hermetic sealing and FKM, NBR, or fluid-resistant O-rings, keying to prevent mismating, a scoop-proof interface for reliable mating, and multiple layouts for up to 121 signal and control, medium- and high-power, and high-frequency contacts. Solutions are rated for up to 250VAC (service level one) or 650VAC (service level two), for 5–33A per contact, depending on arrangement, and for up to 600A and 2,000VAC for power arrangements.

s DEUTSCH 9316 Series Connectors are designed to ensure safety and survivability in extremely harsh marine applications with depths up to 7,500m, pressures up to 750 bar (10,875psi), and temperatures up to 190°C, including underwater control systems, submarines, offshore oil platforms and loading buoys, subsea motors and compressors, and wellheads. The rugged, explosion-proof series is Ex- and ATEX-approved, hermetically sealed, and easy to use. It features stainless steel shells in front- and rear-mount circular or square bulkhead receptacle configurations, glass-to-metal hermetic sealing and FKM, NBR, or fluid-resistant O-rings, keying to prevent mismating, a scoop-proof interface for reliable mating, and multiple layouts for up to 121 signal and control, medium- and high-power, and high-frequency contacts. Solutions are rated for up to 250VAC (service level one) or 650VAC (service level two), for 5–33A per contact, depending on arrangement, and for up to 600A and 2,000VAC for power arrangements.

PEI-Genesis stocks Falcon Series Connectors from Trolex, which are engineered to provide extremely rugged, user-friendly solutions for power, data, and fiber cables in hazardous-area applications including mining, tunneling, and on- and offshore oil and gas equipment, wellhead control panels, mobile skid units, process plants, portable equipment, and mobile machinery. The Ex-approved series features a rear-loading assembly system that enables complete cable termination in just minutes without any specialized tools or equipment, a two-point radial fixing mechanism to eliminate cable rotation, a two-stage bayonet coupling system that supports exceptionally fast mating and unmating with maximum safety and has a high tolerance for debris and contamination, and shrouded flame paths that are never exposed to potential damage. It also offers live disconnect capabilities to mitigate equipment downtime and ease of maintenance and equipment changeouts. Options include Falcon 25 connectors with 4–10 contacts and live disconnect capabilities for control circuits and medium-power applications, Falcon 25 Flash connectors with 32GB flash drives and optional desktop PC readers for control device data downloads, Falcon 25 Fibre connectors equipped with Cinch Connectivity Solutions’ expanded beam optical fiber connectors and available in two, four, or eight single- or multi-mode channels for high-speed, high-density data transfer, and Falcon 40 High-Capacity connectors with live disconnect capabilities and up to 37 contacts for multi-way control circuits and power distribution.

stocks Falcon Series Connectors from Trolex, which are engineered to provide extremely rugged, user-friendly solutions for power, data, and fiber cables in hazardous-area applications including mining, tunneling, and on- and offshore oil and gas equipment, wellhead control panels, mobile skid units, process plants, portable equipment, and mobile machinery. The Ex-approved series features a rear-loading assembly system that enables complete cable termination in just minutes without any specialized tools or equipment, a two-point radial fixing mechanism to eliminate cable rotation, a two-stage bayonet coupling system that supports exceptionally fast mating and unmating with maximum safety and has a high tolerance for debris and contamination, and shrouded flame paths that are never exposed to potential damage. It also offers live disconnect capabilities to mitigate equipment downtime and ease of maintenance and equipment changeouts. Options include Falcon 25 connectors with 4–10 contacts and live disconnect capabilities for control circuits and medium-power applications, Falcon 25 Flash connectors with 32GB flash drives and optional desktop PC readers for control device data downloads, Falcon 25 Fibre connectors equipped with Cinch Connectivity Solutions’ expanded beam optical fiber connectors and available in two, four, or eight single- or multi-mode channels for high-speed, high-density data transfer, and Falcon 40 High-Capacity connectors with live disconnect capabilities and up to 37 contacts for multi-way control circuits and power distribution.

Cinch Connectivity Solutions’ Fibreco brand Geo-Beam Connector Series are engineered to mate with Ex- and ATEX-approved OPIS (inherently safe optical radiation) transceivers, provide high-reliability, high-speed fiber optic connectivity, and reduce non-productive time (NPT) in applications with potentially explosive environments, including oil and gas equipment. The Geo-Beam EX Electrical/Optical and Expanded-Beam Connectors are Ex- and ATEX-approved for use in Zone 1 hazardous areas and offer great flexibility in terms of connector configurations and options. Geo-Beam EX Electrical/Optical Connectors feature an eight-way copper connector, a standard #16 MIL-C-39029 contact, and a variable range of fiber configurations that employ MIL-PRF-29504, physical contact, and optical termini. Geo-Beam EX Expanded-Beam Connectors feature standard Fibreco inserts that support up to eight expanded-beam channels or a hybrid combination of power, electrical, and optical connectivity.

Cinch Connectivity Solutions’ Fibreco brand Geo-Beam Connector Series are engineered to mate with Ex- and ATEX-approved OPIS (inherently safe optical radiation) transceivers, provide high-reliability, high-speed fiber optic connectivity, and reduce non-productive time (NPT) in applications with potentially explosive environments, including oil and gas equipment. The Geo-Beam EX Electrical/Optical and Expanded-Beam Connectors are Ex- and ATEX-approved for use in Zone 1 hazardous areas and offer great flexibility in terms of connector configurations and options. Geo-Beam EX Electrical/Optical Connectors feature an eight-way copper connector, a standard #16 MIL-C-39029 contact, and a variable range of fiber configurations that employ MIL-PRF-29504, physical contact, and optical termini. Geo-Beam EX Expanded-Beam Connectors feature standard Fibreco inserts that support up to eight expanded-beam channels or a hybrid combination of power, electrical, and optical connectivity.

Heilind Electronics stocks Amphenol Industrial’s AMPHE-EX Hazardous Environment Connectors, which have a smaller interface than most heavy-duty, hazard-rated connectors, exhibit rugged resistance to high temperatures, harsh chemicals, and even explosions, and are Ex- and ATEX-approved for use in Zone 1 and 2 applications. The series supports the high-reliability transmission of signal, power, RF, fiber optic, and Ethernet in harsh-environment applications including chemical and pharmaceutical manufacturing, petrochemical refineries, and on- and offshore drilling platforms, and is available in several different IP68 shell styles machined from high-grade aluminum, brass, or stainless steel, plated with a scratch- and corrosion-resistant hard anodic coating per MIL-A-8625 Type III, and equipped with easy-mating double-lead acme threads that exhibit self-cleaning action to avoid threads clogged with ice, snow, mud, or sand. Options include panel-mount, flangeless panel-mount, fixed in-line, and flangeless in-line receptacles and plugs with EX cable glands, numerous alternate insert rotations to prevent mismating, flexible insert layouts designed around MIL-DTL-38999 standards and equipped with copper, fiber optic, coaxial, or mixed conductors or RJ45 or USB connectivity, large-wire-spacing backshells for easy contact installation, and a variety of cable styles, including unarmored, armored, sheathed, and high-flex cables.

stocks Amphenol Industrial’s AMPHE-EX Hazardous Environment Connectors, which have a smaller interface than most heavy-duty, hazard-rated connectors, exhibit rugged resistance to high temperatures, harsh chemicals, and even explosions, and are Ex- and ATEX-approved for use in Zone 1 and 2 applications. The series supports the high-reliability transmission of signal, power, RF, fiber optic, and Ethernet in harsh-environment applications including chemical and pharmaceutical manufacturing, petrochemical refineries, and on- and offshore drilling platforms, and is available in several different IP68 shell styles machined from high-grade aluminum, brass, or stainless steel, plated with a scratch- and corrosion-resistant hard anodic coating per MIL-A-8625 Type III, and equipped with easy-mating double-lead acme threads that exhibit self-cleaning action to avoid threads clogged with ice, snow, mud, or sand. Options include panel-mount, flangeless panel-mount, fixed in-line, and flangeless in-line receptacles and plugs with EX cable glands, numerous alternate insert rotations to prevent mismating, flexible insert layouts designed around MIL-DTL-38999 standards and equipped with copper, fiber optic, coaxial, or mixed conductors or RJ45 or USB connectivity, large-wire-spacing backshells for easy contact installation, and a variety of cable styles, including unarmored, armored, sheathed, and high-flex cables.

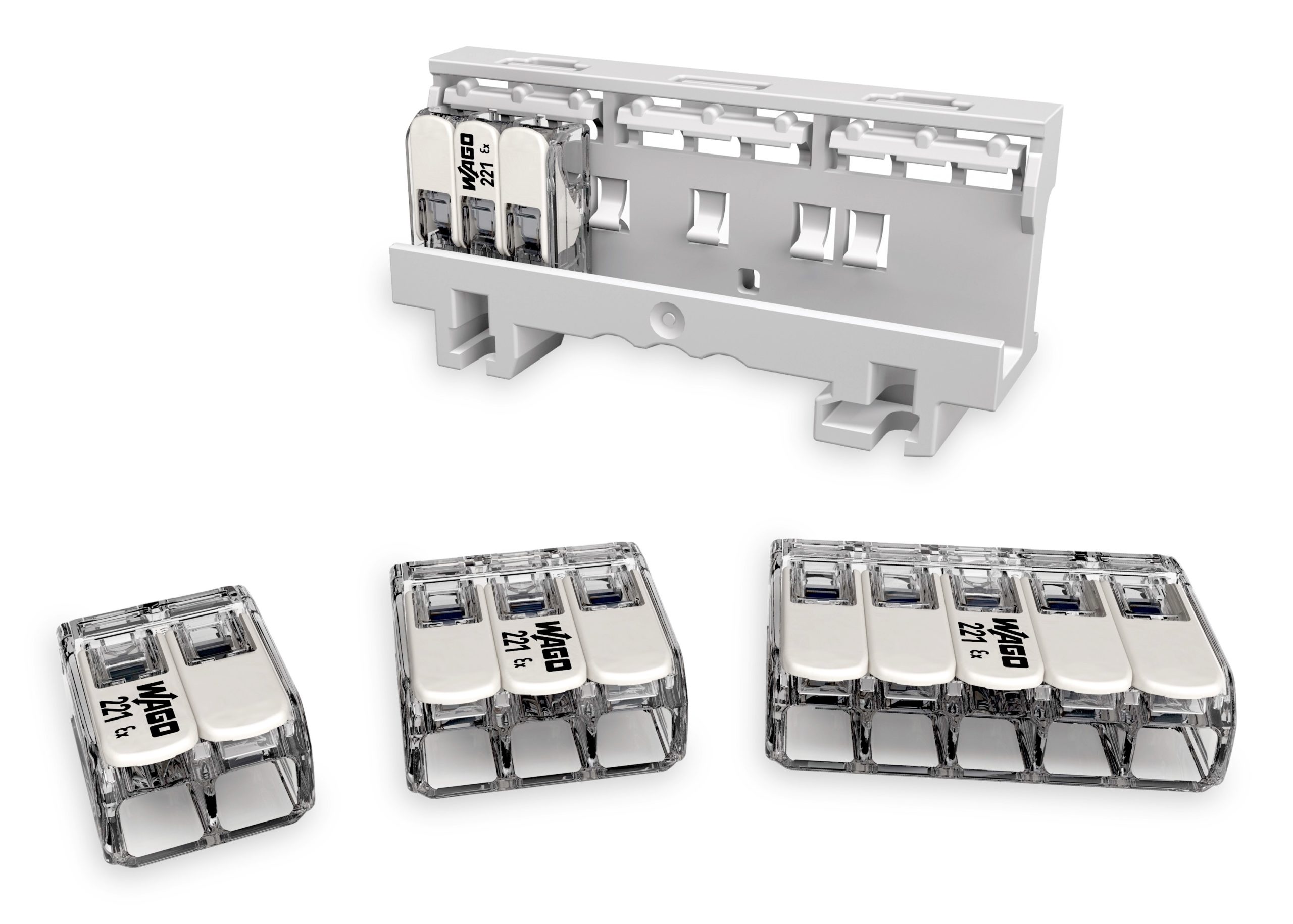

WAGO’s 221 Ex Series LEVER-NUTS splicing connectors enable the quick, easy, and reliable termination of solid, stranded, and fine-stranded conductors in hazardous environments with just three simple steps: Pull the lever up, insert the stripped conductor, and push the lever back down. The 221 Ex Series offers the same space savings and convenience as the rest of the 221 Series, but has gray instead of orange levers and offers Ex-approved Class 1, Zone 1 explosion-proof performance when used in conjunction with the mounting carrier, which can be either clamped onto a DIN rail or screwed tightly to any smooth surface. It is rated for 24–12AWG wire and for up to 440V with spacing between adjacent connectors in the mounting carrier or up to 275V without spacing.

WAGO’s 221 Ex Series LEVER-NUTS splicing connectors enable the quick, easy, and reliable termination of solid, stranded, and fine-stranded conductors in hazardous environments with just three simple steps: Pull the lever up, insert the stripped conductor, and push the lever back down. The 221 Ex Series offers the same space savings and convenience as the rest of the 221 Series, but has gray instead of orange levers and offers Ex-approved Class 1, Zone 1 explosion-proof performance when used in conjunction with the mounting carrier, which can be either clamped onto a DIN rail or screwed tightly to any smooth surface. It is rated for 24–12AWG wire and for up to 440V with spacing between adjacent connectors in the mounting carrier or up to 275V without spacing.

RS Components Americas stocks PRE Series Ex- and ATEX-approved Connectors from Emerson Network Power. Engineered for extreme environmental protection, these 16A plugs and sockets provide high-reliability power transmission in potentially corrosive and explosive oil and gas industry applications, including refineries, chemical and petrochemical plants, pipelines, loading docks, and on- and offshore drilling platforms, and in a range of portable and stationary industrial applications, including lighting systems, conveyors, heaters, motor generators, air conditioning equipment, compressors, and pumps. The series offers IP66 ingress protection, IK09/10 (i.e., 10/20 joules) impact protection, and 20kA short-circuit protection (versus the usual 10kA) and is approved for use in ATEX Zone 1 and 2 hazardous gas, vapor, and mist environments, ATEX Zone 21 and 22 hazardous dust environments, and IECEx II 2 GD above-ground environments exposed to hazardous gas, vapor, mist, and dust. PRE Series plug and socket assemblies are equipped with patented, silver-plated linear switches that totally disconnect power upon plug removal, dedicated flameproof chambers for high-voltage contacts, and secondary flameproof chambers that support the automatic electrical connection and disconnection of each phase and are keyed to accept only ATX power supply plugs and color-coded to enable the easy identification of different voltage ratings. Options include plugs and wall-mount, flush-mount, and mobile sockets made of rugged polycarbonate, polyester, or polyamide materials, two or three power pins and optional earthing/grounding and neutral pins, integrated cable glands, and voltage ratings extending up to 50VDC and up to 500VAC at 50–60Hz or 300–500Hz.

RS Components Americas stocks PRE Series Ex- and ATEX-approved Connectors from Emerson Network Power. Engineered for extreme environmental protection, these 16A plugs and sockets provide high-reliability power transmission in potentially corrosive and explosive oil and gas industry applications, including refineries, chemical and petrochemical plants, pipelines, loading docks, and on- and offshore drilling platforms, and in a range of portable and stationary industrial applications, including lighting systems, conveyors, heaters, motor generators, air conditioning equipment, compressors, and pumps. The series offers IP66 ingress protection, IK09/10 (i.e., 10/20 joules) impact protection, and 20kA short-circuit protection (versus the usual 10kA) and is approved for use in ATEX Zone 1 and 2 hazardous gas, vapor, and mist environments, ATEX Zone 21 and 22 hazardous dust environments, and IECEx II 2 GD above-ground environments exposed to hazardous gas, vapor, mist, and dust. PRE Series plug and socket assemblies are equipped with patented, silver-plated linear switches that totally disconnect power upon plug removal, dedicated flameproof chambers for high-voltage contacts, and secondary flameproof chambers that support the automatic electrical connection and disconnection of each phase and are keyed to accept only ATX power supply plugs and color-coded to enable the easy identification of different voltage ratings. Options include plugs and wall-mount, flush-mount, and mobile sockets made of rugged polycarbonate, polyester, or polyamide materials, two or three power pins and optional earthing/grounding and neutral pins, integrated cable glands, and voltage ratings extending up to 50VDC and up to 500VAC at 50–60Hz or 300–500Hz.

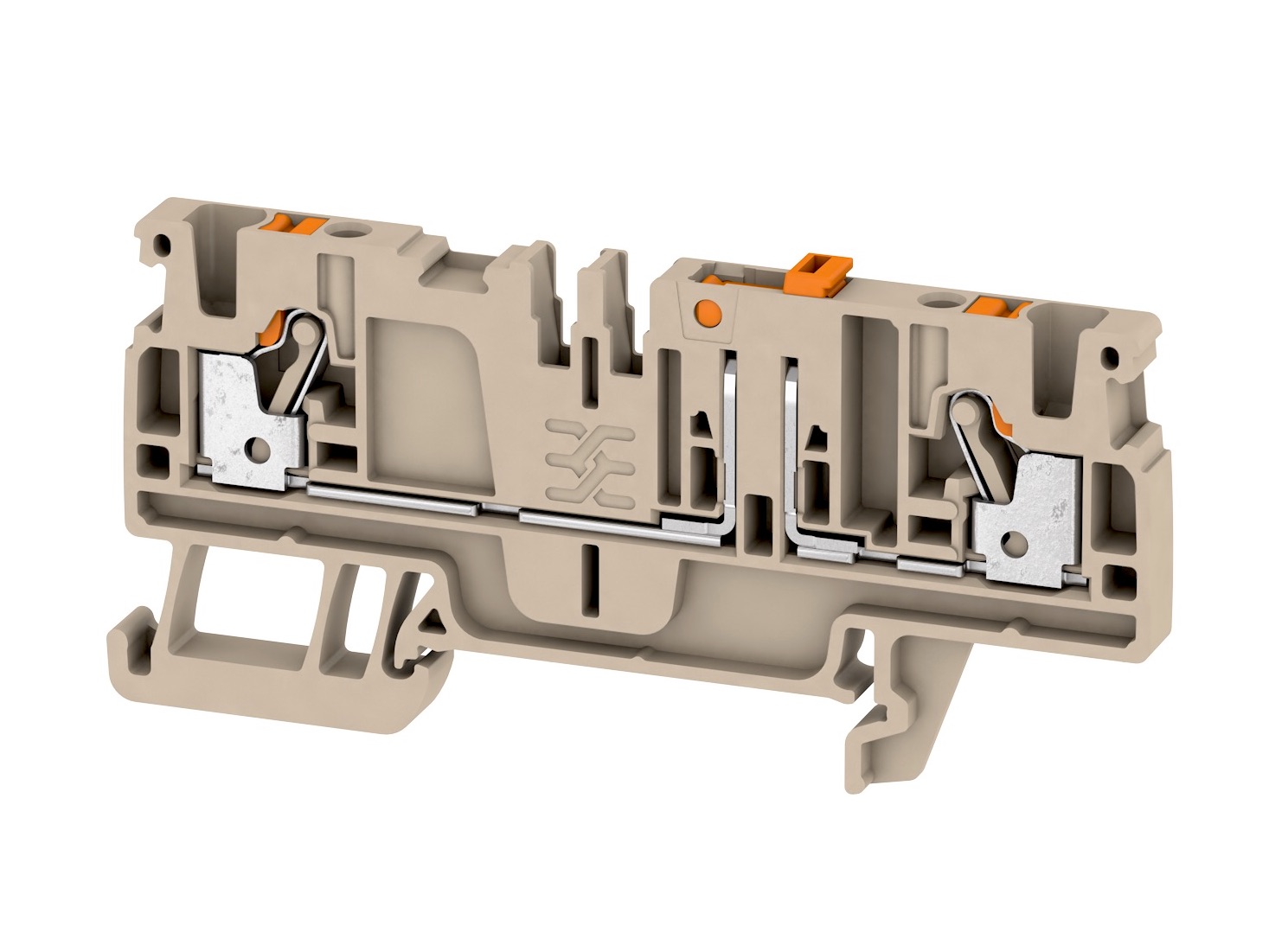

Weidmuller’s Klippon® Connect Universal Range terminal blocks with PUSH IN technology are designed to improve installation efficiency in a vast range of harsh-environment applications without compromising on safety. The innovative PUSH IN direct plug connectors allow users to achieve safe, vibration-resistant, and gas-tight connections by simply inserting a conductor into the clamping unit until it stops, reducing connection times for both solid and ferruled wires by up to 50% compared to clamping yoke terminals. They also allow users to terminate flexible conductors quickly, easily, and without tools, and to release conductors with any tool. These modular terminal blocks have a streamlined design, high mounting density, copper power rails, a stainless steel spring, a consistent test point, optical and physical segregation of operation and conductor entry, large marking surfaces to support efficient maintenance, and a mounting foot that both compensates for differences in dimensions of terminal rails and facilitates removal. To facilitate application flexibility, they are also available with an extensive array of accessories and cross-connection options. In addition, A-Series options in the range offer several Ex- and ATEX-approved solutions, including the ADT 2.5 2C modular test-disconnect terminal block, which also features a compact and lightweight form factor, is rated for up to 20A, 400V, and continuous operating temperatures extending from -60°C to +130°C, and is compliant with UL94 V-0 and RoHS requirements.

Weidmuller’s Klippon® Connect Universal Range terminal blocks with PUSH IN technology are designed to improve installation efficiency in a vast range of harsh-environment applications without compromising on safety. The innovative PUSH IN direct plug connectors allow users to achieve safe, vibration-resistant, and gas-tight connections by simply inserting a conductor into the clamping unit until it stops, reducing connection times for both solid and ferruled wires by up to 50% compared to clamping yoke terminals. They also allow users to terminate flexible conductors quickly, easily, and without tools, and to release conductors with any tool. These modular terminal blocks have a streamlined design, high mounting density, copper power rails, a stainless steel spring, a consistent test point, optical and physical segregation of operation and conductor entry, large marking surfaces to support efficient maintenance, and a mounting foot that both compensates for differences in dimensions of terminal rails and facilitates removal. To facilitate application flexibility, they are also available with an extensive array of accessories and cross-connection options. In addition, A-Series options in the range offer several Ex- and ATEX-approved solutions, including the ADT 2.5 2C modular test-disconnect terminal block, which also features a compact and lightweight form factor, is rated for up to 20A, 400V, and continuous operating temperatures extending from -60°C to +130°C, and is compliant with UL94 V-0 and RoHS requirements.

HARTING’s Han Ex NEC 500 Class I Division II Connector Series meets all electrical requirements for implementing high-quality connectivity solutions in hazardous locations in the Americas and is especially well suited for use in energy industry applications including power generation, alternative energy systems, oil and gas exploration, petrochemical processing, mining operations, and fuel storage sites. The Ex-approved series features housings that are made from a special alloy designed to withstand pulverized methane-coal dust atmospheres and are colored blue to indicate use in potentially hazardous locations. It is available in various hood and housing sizes with 3–24 contacts and IP65 or IP67 protection when mated and is capable of supplying up to 90V and 16A in operating temperatures spanning -20°C to +40°C. The series is also available with various termination technologies, including traditional crimp and screw varieties and HARTING’s patented Han-Quick Lock technology, which enables easy, time-saving assembly without any special tools. Additional features include metal locking levers that require tools to open to prevent unintentional disconnection in explosive atmospheres, improved vibration resistance and safety features, and high-density contact inserts for critical space savings.

Bulgin’s EXP Series connectors are explosion-proof versions of its 900 Series high-power Buccaneer connectors, which features IP68 and IP69K sealing, secure screw thread locks for safe, high-voltage connections, and UL, CSA, and VDA approvals, and is rated for up to 32A, 600V. Suitable for use in ATEX Zone 2 (gas) and Zone 22 (dust) applications including oil and gas, mining, and power generation equipment, motors, pumps, and lighting equipment, and process and control equipment in factories and plants with hazardous environments and potentially explosive atmospheres, EXP Series connectors have an IP68 ingress protection rating and are available in flex cable, flex in-line cable, front-panel-mount, and flange-mount connector configurations with accessories including heavy-duty sealing caps with stainless steel straps and cable glands.

Bulgin’s EXP Series connectors are explosion-proof versions of its 900 Series high-power Buccaneer connectors, which features IP68 and IP69K sealing, secure screw thread locks for safe, high-voltage connections, and UL, CSA, and VDA approvals, and is rated for up to 32A, 600V. Suitable for use in ATEX Zone 2 (gas) and Zone 22 (dust) applications including oil and gas, mining, and power generation equipment, motors, pumps, and lighting equipment, and process and control equipment in factories and plants with hazardous environments and potentially explosive atmospheres, EXP Series connectors have an IP68 ingress protection rating and are available in flex cable, flex in-line cable, front-panel-mount, and flange-mount connector configurations with accessories including heavy-duty sealing caps with stainless steel straps and cable glands.

Like this article? Check out our other Product Roundup, Product News, and Connector Industry News articles and our 2020 and 2019 Article Archives.

- May 2021 New Connectivity Products - May 4, 2021

- Off-Highway Equipment Connectors Product Roundup - May 4, 2021

- Blind-Mating Coaxial Connectors Product Roundup - April 20, 2021