Waterproof Pogo-Pin Connectors for Portable and Wearable Medical Applications

Small portable and wearable medical technologies give patients and healthcare providers a safer, more flexible tool for collecting vital biometric data and delivering care. These devices handle the harsh operating conditions of the home and clinic with the help of pogo-pin connectors.

As the medical world turns to technology to deliver healthcare in new ways, demand for portable and wearable medical devices is growing rapidly. These devices give patients greater independence, flexibility, and support, and provide healthcare providers with critical, timely information for improved diagnosis and patient care. Portable medical technologies can be used at home and in medical facilities, and they collect and transmit valuable data to the cloud for storage and analysis by medical professionals.

To meet the growing demand for safe, effective portable devices, connector design engineers are developing smaller, more rugged connectivity solutions that can be implemented in compact medical application designs. In addition taking on smaller form factors, these connectors must be rugged enough to withstand the everyday vibration, shock, and general use conditions portable and wearable healthcare equipment experiences in home and institutional environments. In many applications, these connectors must also be able to withstand contact with fluids, including cleaning chemicals. Rugged spring-loaded pogo-pin connectors offer the high-performance and waterproofing characteristics vital to a wide range of portable and wearable medical applications.

Portable and wearable medical devices including glucose monitors are increasingly common and often require smaller and more rugged connectivity components than those employed in clinical environments.

Application Background

The global pandemic has accelerated demand for safe, hands-off, portable, and home-based medical technologies. The global wearable medical device market size was valued at $10.3 billion in 2018 and is estimated to grow to $93.7 billion by 2027. Wearable monitors like glucose meters, insulin monitors, and heart rate monitors are vital for proactive, preventative patient care. To ensure utility and durability in typical use scenarios, these electronics must be adequately protected from everyday hazards, including exposure to liquids and dust. Pogo-pin connectors are a durable and effective connectivity solution for these designs.

Pogo-Pin Connector Contact Structure

Pogo-pin contacts consist of three primary parts: pins, tubes, and springs. The spring-loaded design provides constant lateral pressure against the inside of the tube, which results in steadier connections with better contact resistance than standard connectors.

Pogo-pin connectors feature a floating contact design that allows them to rotate and slide freely within the housing to provide the range of movement required. They also eliminate the need for soldering, which significantly decreases assembly time and cost, and have easily detachable spring pins to help maximize design flexibility. In addition, they are often electroplated with gold over nickel to achieve the high electrical conductivity, increased durability, and corrosion resisistant performance required for use in critical clinical equipment.

Spring-Loaded, Waterproof Cradle Connectors

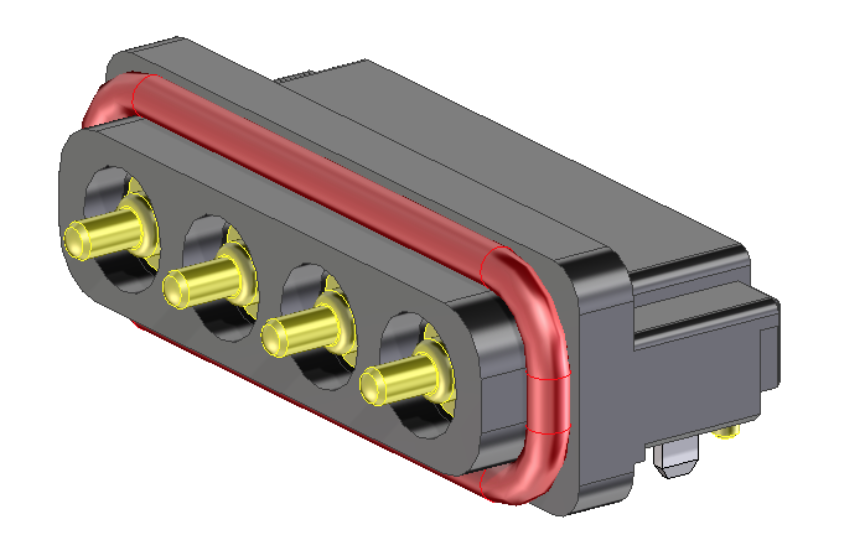

The moving-part construction of pogo pins typically allows for liquids to penetrate through gaps between the actual pogo pin head and surrounding tube, or between the small clearance of the pogo pin when housed inside its plastic holder. However, by reversing the direction of the pogo pins in the housings and incorporating a rubber sheet, the male side (i.e., cradle connector) can effectively prevent seepage.

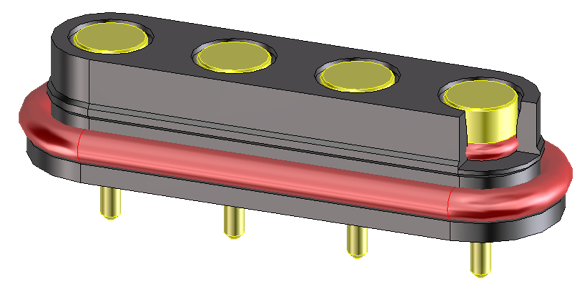

An IPx7-rated waterproof spring-pin receptacle from Yokowo.

Environmental Protection

Like most connectors rated for use in portable and wearable medical equipment, pogo-pin connectors can provide IP-rated protection against ingress of fluids. In spring-loaded connectors, this waterproofing is achieved by installing an O-ring between the contact pin and housing. For example, Yokowo S Series designs can offer IP67-, IP68-, or IP69K-rated protection against liquids like water, vapor, cleaning chemicals, and other liquid contaminates.

Yokowo waterproof pogo-pin connectors are easy to assemble, capable of high-current transmission, and available in more than 60 configurations with IP67, IP68, or IP69K waterproof ratings for broad application suitability in challenging environments.

Durability and Reliability

Deficient connectivity negatively affects the performance of portable medical equipment and can have serious consequences for both patients and operators. Since pogo-pin contacts provide a high, constant mating force, they can robustly withstand shock and vibration, and maintain strong, reliable connections even under demanding conditions.

Waterproof spring-loaded connectors provide excellent durability against repeated extension and retraction, which offers a vital advantage in products with detachable parts and high mating cycles, like portable medical diagnostic and imaging equipment. Advanced vacuum-plated pogo-pin contacts employ a vacuum environment to prevent air pockets from forming. A bleeding hole on the side or bottom of the tube ensures that equal plating is applied to its every surface for maximum durability. As a result, vacuum-plated pogo-pin connectors can deliver up to 100,000 mating cycles.

Size

Recent advancements in manufacturing capabilities have made it possible to develop extremely small diameter waterproof pogo-pins. New waterproof pogo connectors can feature narrow terminal pitches of 2.5mm, an improvement over previous waterproof pogo-pin connectors that were widely available in 3.5mm or 4.0mm pitches. These miniature-pitch pogo-pin connectors provide portable electronics designers with excellent, high-reliability design options for meeting stringent size and weight reduction requests.

Yokowo offers waterproof pogo-pin connectors with miniature pitches down to 2.5mm.

Flexibility

Pogo-pin connectors can also mate with a wide variety of surfaces, as long as the spring-pin makes proper contact with a flat, plated surface. This broad mating compatibility eliminates one side of the traditional pin-and-socket connector system, which saves space, provides significant cost savings and reduces production time.

High-Current Capabilities

Some portable medical electronics require high-current capabilities up to 10A. Pogo-pin connectors can satisfy this demand as well, using advanced insulator technology that offers a much higher current-carrying capacity than the standard ball technology.

Yokowo’s high-current pogo-pin connectors feature insulating technology that enables the pin to endure the increased temperatures that accompany increased currents.

As new portable and wearable options expand the medical device market, pogo-pin connectors will continue to evolve to meet the unique design challenges these applications present. They have already facilitated great advances in this category. While water damage to portable and wearable medical electronics was once considered inevitable, strategic connector choices now prevent damaging liquid seepage into cradle connectors. In addition to critical space savings and reduced costs, waterproof spring-loaded pogo-pin connectors deliver the high-reliability performance required by demanding mobile and wearable medical devices.

Like this article? Check out our other waterproof connector, wearable connectivity, and how-to-specify articles, our Medical Market Page, and our 2021 and 2020 Article Archives.

- Waterproof Pogo-Pin Connectors for Portable and Wearable Medical Applications - February 2, 2021

- Waterproof Connectors for Portable Devices - April 9, 2019