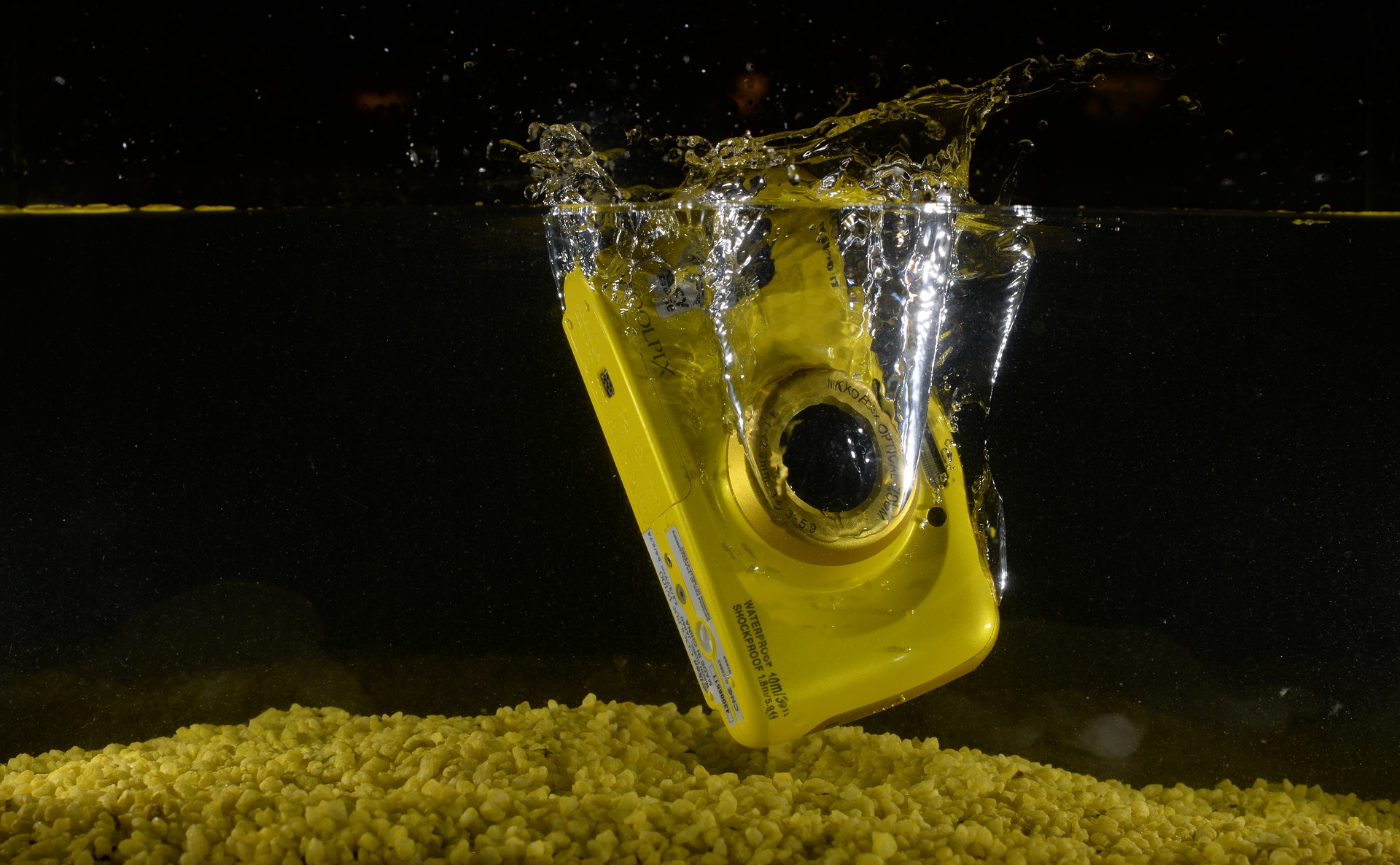

Waterproof Connectors for Portable Devices

Product designers have to account for the real possibility that a small consumer device will get splashed on or dropped into the drink. The right waterproof connector can save the day.

Spilling a drink or splashing water on portable device chargers and ports has long resulted in inevitable device damage. However, the increased prevalence of these devices — especially in the consumer, medical, and industrial markets — and the commonality of their exposure to harsh-environment conditions like splashed water or spilled drinks, has led to the development of waterproof connectors that can both protect these devices from ingress and provide several other useful benefits.

Environmentally sealed spring contacts, or pogo-pin contacts, can offer waterproof protection, critical space savings, and proven high-reliability performance in a range of harsh-environment applications, and often at a lower cost than alternative solutions, which is especially attractive for consumer electronics designs.

Standard Pogo-Pin Connector Designs

Pogo-pin contacts consist of three primary parts — pins, tubes, and springs — and provide constant lateral pressure against the inside of the tube, which results in steadier connections with better contact resistance than many other types of connectors. Pogo-pin connectors feature a floating contact design that allows them to rotate and slide freely within the housing to provide the exact range of movement required and have easily detachable spring pins to maximize design flexibility. They also eliminate the need for soldering, which significantly decreases assembly time and cost. In addition, they are often electroplated with gold over nickel to achieve high electrical conductivity, increased durability, and corrosion-resistant performance required by a wide range of consumer, medical, and industrial equipment.

Yokowo’s S Series pogo-pin connectors provide easy assembly, high current-carrying capabilities, and waterproof performance, and offer more than 60 unique solutions with IP67, IP68, or IP69K ratings for broad application suitability.

Environmental Protection

The moving-part construction of pogo-pin connectors typically allows for liquids to penetrate through gaps between the pogo pin head and surrounding tube or the small clearance area between the pogo pin and its plastic housing. However, like most connectors rated for use in harsh environments, pogo-pin connectors can be made to provide varying levels of IP-rated protection.

In spring-loaded connectors, this is typically achieved by installing an O-ring between the contact pin and housing for waterproofing, but can also be achieved by reversing the direction of the pogo pins in the housing and incorporating a rubber sheet in the male (or cradle) side of the connector to prevent seepage. These assemblies reduce the need for additional waterproofing and guards in device docking stations and terminals.

This diagram illustrates the basic structure of Yokowo’s patented waterproof pogo-pin connectors.

Size

Recent advancements in manufacturing capabilities have made it possible to develop extremely small diameter waterproof pogo pins with narrow terminal pitches of 2.5mm, which is a significant improvement over previous waterproof pogo-pin connectors and is especially beneficial for meeting stringent size and weight reduction demands in portable electronics designs. Earlier iterations of these designs were most readily available with a 3.5mm or 4.0mm pitch.

Waterproof pogo-pin connectors are now available with miniature pitches down to 2.5mm.

Durability

Waterproof pogo-pin connectors also offer excellent durability, delivering up to 100,000 mating cycles in applications with repeated extension and retraction requirements. This capability provides a critical advantage for portable electronic products with detachable parts and high mating cycles. In addition, the pogo-pin contact design provides inherently high and constant mating force, which allows these connectors to ruggedly withstand the shock and vibration commonly experienced by portable and handheld equipment.

Pogo-pin connectors provide numerous design benefits, including design flexibility, reduced installation time and cost, and rugged, high-reliability performance.

Customization

Standard waterproof pogo-pin connectors with a rated current of up to 2A at 12VAC/DC and rated operating temperatures extending from -40° to 85°C are readily available for purchase, but these devices can also deliver custom current ratings, pin sizes, pin counts, and more to match individual application requirements.

Waterproof pogo-pin connectors are experiencing increased cross-market popularity in response to growing demand from manufacturers of cradle or docking chargers, smartphones, tablet PCs, laptops, barcode readers, point-of-sale scanners, handheld GPS devices, medical equipment, and more.

Current and Future Solutions

Waterproof pogo-pin connectors feature numerous characteristics that are beneficial to a wide range of portable electronics applications, including an inherently robust design, high durability, rugged resistance to shock and vibration, small size, light weight, a broad selection of standard offerings, customization capabilities, and extensive design flexibility. As such, this technology will continue to evolve to meet the steadily increasing demand for portable electronics across multiple markets and the desire for ever smaller, lighter weight, more durable, higher performance, and environmentally resistant component solutions.

By Kensuke Oe, Senior Sales Manager at Yokowo America Corp.

Like this article? Check out our other Connector Basics and High-Speed articles, our 2019 article archive, and our Markets page.

- Waterproof Pogo-Pin Connectors for Portable and Wearable Medical Applications - February 2, 2021

- Waterproof Connectors for Portable Devices - April 9, 2019