What are spring probes?

Meet the Connector: Spring Probes (Contact Probes)

Spring probes, also called contact probes or spring-loaded probes, are an essential component in the testing of electronic components. In Test & Measurement applications, they are used to make contact with test points, connecting the DUT (device under test) with the test equipment. Spring probes are also used to perform functional tests (FCT) on the DUT to test its performance under conditions that simulate or are almost equal to the working conditions in which the equipment will be used.

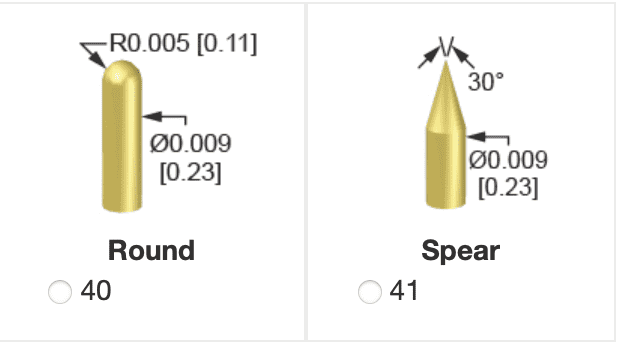

QA Technology’s test probes include springs designed to be used at working stroke, typically 2/3 of the rated full stroke. This maximizes the cycle life of the probe without the risk of over stressing the spring. Round or spear tip types are available.

Spring probes are a simple assembly consisting of a spring, tube or barrel, and plunger. To operate, pressure is applied to the plunger or pin, which then causes the spring to compress within the barrel. Distance between the barrel and the spring prevents friction from degrading the parts. Spring contact probes come in a variety of configurations, including bias ball designs, different lengths, installation methods, grid sizes, head shapes, spring loads, and types of connection. Common variations include:

- ICT/FCT standard

- Double plunger probe

- Battery probe

- Switch probe

- High current probe

- Flying probe

- Solderable probe

- Threaded probe

- Inserters/extractors

- Interface contacts

- Rigid pins (used to test bare circuits, these pins do not have a spring mechanism)

Spring probes also function as part of a connector assembly in spring-loaded contacts. In a connector, an additional mechanism may be used to lock the pin in the compressed position. Spring probe connectors are compliant on the surface of their mating half, instead of extending into it as with conventional pin and socket connectors. This gives spring probes excellent blind-mate capabilities.

Design Notes

- Materials Brass, bronze, or copper are commonly used as the base material for the plunger and barrel of spring-loaded pins, with a thin layer of silver nickel applied to the surface. Gold plating improves the durability and contact resistance. The springs are usually made of spring steel or copper alloys. The plunger may be copper, steel, or other materials, depending on the test specifications.

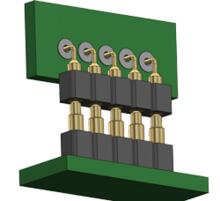

- Connector arrangement Spring-loaded pins are typically arranged in a dense array. In automatic test equipment, a “bed of nails” configuration facilitates the rapid and reliable connection of devices under test (DUTs). In high-performance applications, the arrangement must allow high reliability through many mating/unmating cycles and high-fidelity transmission of electrical signals. In matched impedance circuits, the pins may be arranged with one signal-carrying pin surrounded by grounded pins.

A board-to-board configuration featuring Mill-Max spring contacts.

- Magnets may be added to improve the strength and reliability of the connection. This is done in consumer electronics and high-frequency data transfer applications.

- Spring load is the amount of load that corresponds with the operating stroke of the plunger. This is specified during the selection of the contact probe and will increase as the probe’s travel increases.

- Spring probe interposers can achieve speeds of 12 Gb/s and bandwidths of 20 GHz. Spring probe connectors can also be made coaxial by adding insulators and metal interposer bodies.

Spring probes from Smiths Interconnect feature IDI technology and are designed to optimize performance in high reliability, multicycle applications.

Markets, Sectors, and Applications

Medical, Military and Aerospace, Test & Measurement, Automotive, 3C

Spring contact probes are used in high density, board-to-board, battery contact, test, and high frequency applications.

Suppliers

Harwin, KYOCERA AVX, Mill-Max, Preci-Dip, QA Tech, Smiths Interconnect, TE Connectivity, Everett Charles Technologies, 3M, Staubli

Related products:

Like this article? Check out our other Meet the Connector and our Medical Market Page, and our 2022 and 2023 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024