Artificial Intelligence Brings Precision and Insights to Computer-Assisted Surgery

New developments in artificial intelligence are making computer-assisted surgery more precise, less invasive, and more successful than ever.

Artificial Intelligence in Computer-Assisted Surgery

Computer-assisted surgery, also called image-guided surgery (IGS), has been a key player in the operating room for more than two decades. IGS provides surgeons with real-time 3-D images of body structures, including organs and bones, to guide precise movements of a scalpel or laser for maximum success and minimal recovery time. In delicate procedures such as neurosurgeries, surgeons can view on a computer screen real-time images of areas of the brain that were once too difficult to operate on due to location or complicated tumor dimensions. IGS can be used to collect measurements and other data, plan surgical access points, track instruments as they move, and monitor conditions in the surgical site and the patient during the procedure.

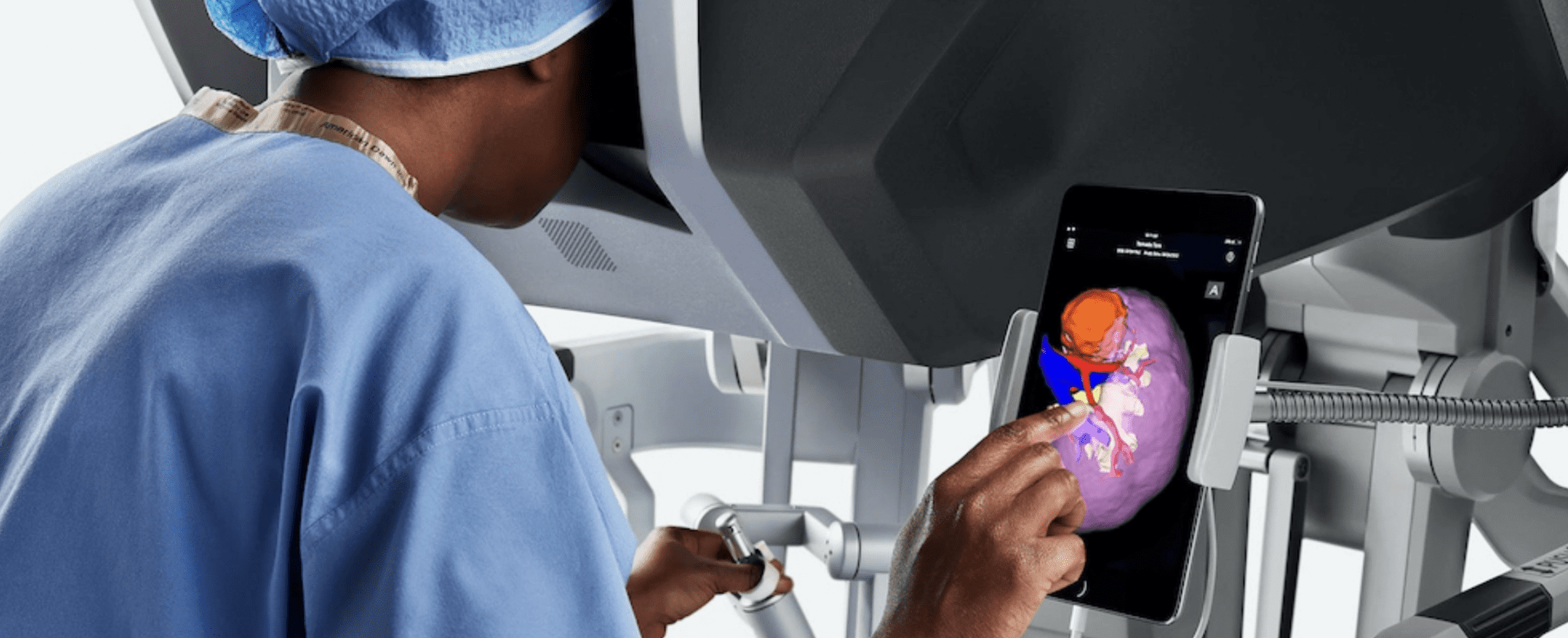

The da Vinci surgical robot performs computer assisted and remote procedures.

New technologies that integrate IGS with artificial intelligence (AI), augmented reality (AR), and virtual reality (VR) will further reduce errors and improve recovery times and outcomes for patients. Surgeons can use AI platforms such as PeekMed to review historical data and past procedures to create a surgical plan. AR improves surgeons’ intraoperative vision of the surgical site and surrounding area with comparisons to a baseline preoperative image and assessments of real-time changes.

AI can also combine with machine learning to minimize the need for more invasive treatments. For instance, thermal imaging can be used to assess internal structures and minimize the need for radiation technologies such as X-ray or MRI. “While thermography cannot entirely replace these diagnostic tools, it can be used to monitor a patient’s condition in real time, also reducing the need for exploratory surgery,” said David Pike, explaining the technology for Mouser Electronics.

Samtec mPower® Ultra Micro Power Connection System, available from Mouser Electronics, features micro 2mm-pitch 18A power blade interconnects designed for power only or for staging a combination power and signal / ground solution. This micro, high-power solution delivers design flexibility for power-only or power/signal applications, including advanced medical technologies and other harsh environment applications.

LEMO’s B Series of push-pull connectors, available from PEI Genesis, is a secure, push-pull latching system with high-density panel spacing, full EMI shielding, and quick mating or unmating for fast equipment changes in critical medical environments.

High-reliability interconnects are at the heart of these advancements. Connector suppliers work closely with medical device designers to expand the capabilities of imaging and data technologies with the help of flexible, lightweight, and high-speed components. New products that combine functionalities, such as connectors that can transmit power, signal, gases, and fluid, can be united with rugged yet flexible circuits and switches, enhanced sensors, antennas, catheters, and integrated assemblies to generate high quality images in real time, guiding the surgeon’s progress.

Robotic-assisted surgery, such as that enabled by the da Vinci surgical suite, integrates all of these technologies to relieve surgeon stress, improve precision, and minimize surgical damage to tissues by operating with the smallest possible disruption. It even allows the surgeon to operate remotely when the patient is in far-away locations. Medical schools are also bringing these technologies into the learning process, enabling students to “perform” surgery on virtual models. A control platform and robots perform the surgery with intraoperative human oversight via monitor. AI can also reduce the need for surgery in the first place by offering early detection and diagnosis.

Hirose Electronics has focused on miniaturization in new product developments for the medical market. The FunctionMax high-speed transmission, 0.5mm pitch 2.0-3.0mm height with ground plate high-speed board-to-board enables designers to create lightweight, compact devices while increasing speed and reliability.

Many interconnects work in concert throughout the data processing operations, imaging technologies, robots, and devices used to deliver advanced surgical care. An imaging system can include high-speed mezzanine connectors for the control board and monitor connections, USBs for device connections, and FPC connectors for devices and robotics that require flexibility for movement. Miniaturization, ruggedness, and high reliability are key qualities required by components designed into medical robotics and devices.

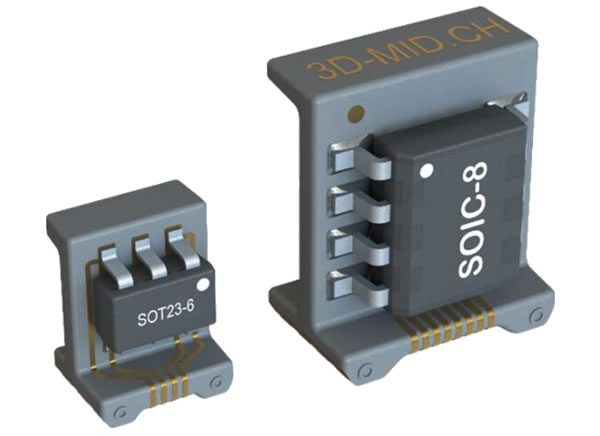

HARTING’s 3D Circuits platform with 3D-MID technology combines electronic and mechanical functions in one component that integrates all the circuitry into one carrier component that can form the functional basis for small medical equipment.

Many of the connectors used in these devices cross markets in functionality. Applications in the military/aerospace, consumer, and industrial markets also require small, lightweight, and high-reliability features, and interconnects designed for one of these markets may easily cross over to the next.

Smiths Interconnect signal and power ARINC 628 connectors serve medical as well as mil/aero and industrial applications with a design that focuses on reliability under intense use conditions. They feature hyperboloid contact technology and quick disconnect push button release good for up to 100,000 mating cycles.

For many medical applications, however, an additional consideration is resistance to bacterial growth and cleanability. Connectors made with sterilizable materials that endure sterilization processes play a role in safety. Connectors often cannot be housed inside the protective casing of the machine, such as connectors that supply power or connect to device attachments. These must be made from antimicrobial plastics and metals and resist cleaning, disinfection, and sterilization processes.

ODU Medi-Snap connectors, available from Mouser Electronics, are suitable for robotic surgical tools. They offer a space-saving, lightweight design, sterility and chemical resistance, and breakaway ease of connection and disconnection through a push-pull mechanism.

The da Vinci and other early high-tech surgical platforms are rapidly being joined by a new generation of equipment that emphasizes high-speed connectivity and communication across devices, platforms, and distances. In the high-stakes operating theater, high-reliability connectors help deliver positive outcomes for patients and providers.

Like this article? Check out our other articles on high-reliability connectors, our Medical Market Page, and our 2023 and 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- State of the Industry: 2022-2023 Connector Sales - April 16, 2024

- Amphenol is On a Roll - April 2, 2024

- Nicomatic Proves That Two Heads are Better Than One - March 26, 2024