What are Push-Pull Circular Connectors?

What are Push-pull Connectors?

Meet the Connector: Push-pull Connectors

Push-pull connectors are circular connectors that have a spring-action cylindrical sleeve surrounding — or within — the integral connector housing that self-latches during mating. The connection is released through a squeeze-and-pull, rotate-and-pull, or other specific unlocking action that prevents accidental disconnection. Push-pull circular connectors are available in numerous sizes, voltages, and pin counts, and in coaxial, triaxial, fluidic, and pneumatic configurations.

The push-pull circular connector was invented by engineer and LEMO Connectors founder Léon Mouttet after he attended a 1954 electronics exhibition in Milan. At the show, he surveyed the standard circular connector selection — mainly screw-thread or bayonet-locking circular connectors — and noticed a problem: Those connector types require time and two hands to mate. Mouttet developed a quick-locking alternative solution, taking inspiration from the spring action used in car cigarette lighters. His new circular connector design eventually became the Push-Pull LEMO B Series connector.

Since then, many connector companies have launched proprietary push-pull circular connectors with unique properties that serve specific markets and applications.

LEMO’s B Series Push-Pull Connector. When a surgeon told LEMO’s retired sales director Walter Straessle, “If your connector disconnects and we fail the operation, it will be your fault!” Straessle replied, “No problem, it will not disconnect.”

Handling Advantages

Ergonomic handling is the hallmark of this circular connector type. The push-pull locking mechanism allows users to easily mate or disconnect equipment with just one hand, even in blind mating situations. An audible or tactile “click” assures the user that the connection is complete and secure; no double-checking or visual confirmation is needed. This enables users at every skill level to quickly and reliably connect equipment. Keying, color coding, and LED options increase that reassurance.

ITT Cannon’s PL Series plastic push-pull circular connectors are disconnected by pulling on a release sleeve on the outer shell.

Design Notes

- Standards No single certification or standard guides the design of push-pull circular connectors, leading to a huge range of variation and very few examples of interoperability across manufacturers. Many push-pull products are designed and tested to meet market-specific standards such as the medical electrical safety standard IEC 60606-1 and the military durability standard MIL-STD-810F.

- Mating cycles Push-pull circular connectors are typically designed for a minimum of 2,000 mating cycles for plastic versions and 5,000 mating cycles for metal versions.

- Spacing No bulky tools are needed to connect push-pull connectors, so they may be mounted closely together, as they only require two fingers to grip the shell to connect or disconnect. (Additional clearance is needed for push-pulls that require a twist motion to disconnect.)

- Materials Metals used for push-push connector shells include copper, stainless steel, gold, and alloys. In the medical market, plastic or polymer options are favored for cleanability and aesthetics. The materials used in medical equipment are typically crush-proof as well as able to withstand autoclave, UV sterilization, and other disinfection processes. In some cases, biocompatible materials may be required. Push-pulls used in space and other markets may need to meet outgassing requirements.

- Ruggedization Push-pull circular connectors and their cable assemblies are available with specific durability attributes for harsh environment applications, including those exposed to temperature extremes, radiation, rough handling, chemicals, and other environmental factors.

- Sealing Many manufacturers offer push-pull connectors with IP-rated protection against fluid and particulate ingress. Hermetic sealing within the connector can be enhanced with silicone O-rings and flexible polymer jacketing surrounding the cable assembly.

- Interference Electromagnetic interference (EMI) or radio-frequency interference (RFI) is a significant concern in environments filled with electronic equipment, such as medical settings and aviation. The use of metal in the shell and ground terminal helps mitigate this concern and enhanced shielding is available from some manufacturers.

binder’s subminiature push-pull connector is suitable for industrial applications.

Markets, Sectors, and Applications

Medical (portable, handheld, diagnostic equipment), industrial (automation controls, robotics), Test & Measurement (analyzers, test equipment), A/V (event wiring, broadcast equipment), communications (antennas, radar, radio equipment), automotive (diagnostic and production equipment), mil/aero (soldier-worn equipment, portable devices), transportation (rail signaling, monitoring, and control systems)

Bernier’s CMA Series are designed for use in harsh environments. These connectors serve radio equipment, soldier systems, and tactical equipments.

NorComp’s QUIK-LOQ ruggedized and waterproof push-pull circular connectors are available in a disposable option.

Suppliers

The circular push-pull is available in many variations from many manufacturers, including Airborn, Amphenol LTW, Amphenol Pcd, Bernier, binder, Fischer Connectors, Hirose Electric, ITT Cannon, LEMO (from Heilind), JAE, Molex, Neutrik, NorComp, PEI Genesis, Phoenix Contact, and Samtec.

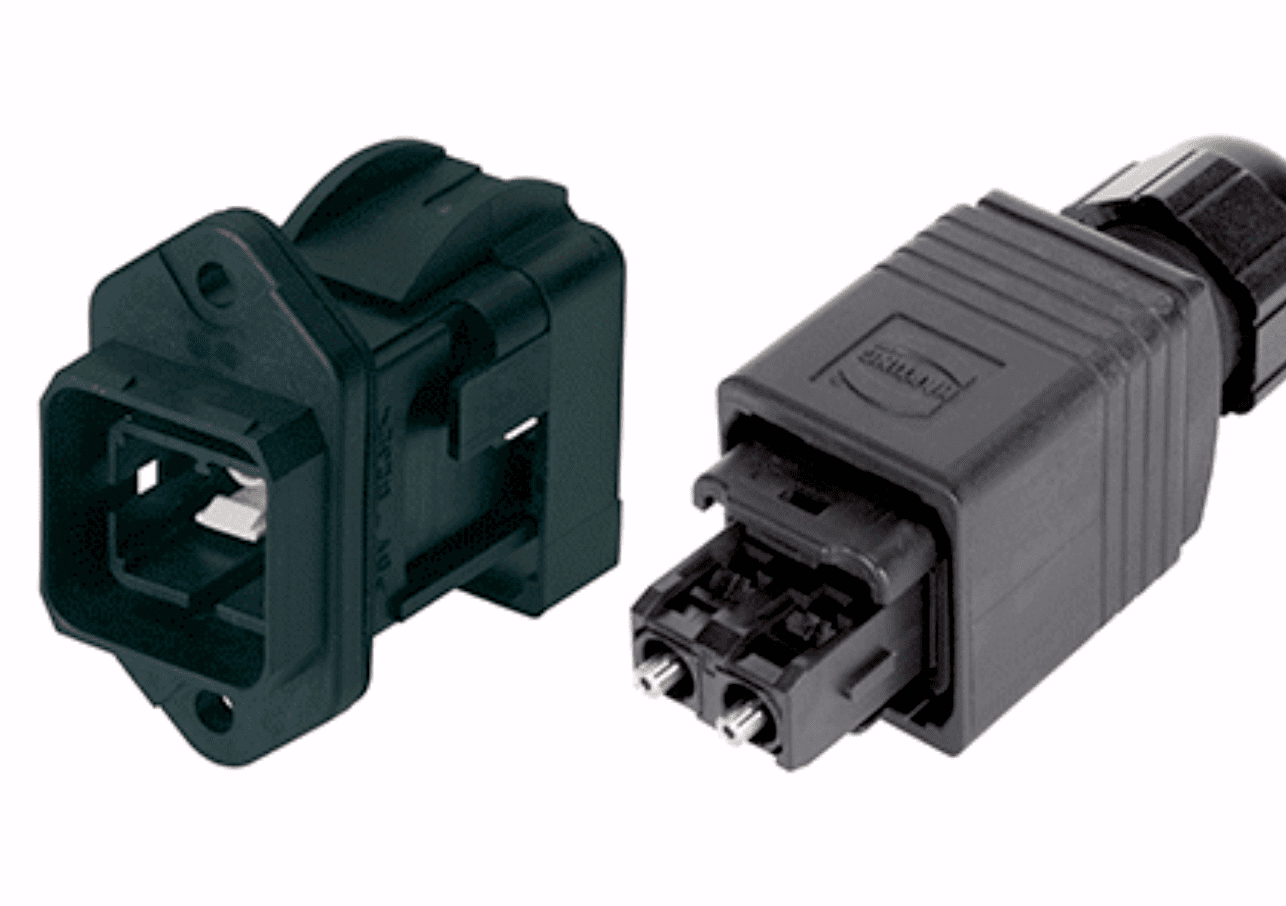

Some industrial push-pull connectors feature a rectangular or square body, such as HARTING’s PushPull.

Related Products

- XLR connectors

- Bayonet connectors

- LC connectors

- Circular DIN connectors

- Circular Metric connectors

- Circular MIL-Spec connectors

- Standard circular connectors (screw-type, bayonet locking, etc.)

- M12-type push-pull connectors (used in rail and industrial applications)

Like this article? Check out our other Meet the Connector, circular connectors, and Market Update articles, our Medical Market Page, and our 2021 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Meet the Connector: DIN Standard Connectors - April 16, 2024

- Software-Driven Radio Reinvigorates Old Technology - April 9, 2024

- What is a Busbar? - April 2, 2024