Five Common Solutions for Connecting Two Industrial Ethernet Cables

How do you connect two Ethernet cables to each other while maintaining environmental ratings, signal integrity, and data speeds? We examine the capabilities, pros, and cons of five common solutions.

By Nate Owens, Product Marketing Manager, Industrial Field Connectivity, and Sam Hartman Product Marketing Specialist, Industrial Field Connectivity, Phoenix Contact USA Industrial Ethernet

How do you connect two networking cables while maintaining environmental ratings, signal integrity, and data speeds? We examine five common solutions for connecting two Industrial Ethernet cables, along with their various pros and cons.

1. Put a pluggable RJ45 connector on it.

For residential or office wiring, RJ45 connectors are readily available and relatively easy to terminate. These types of Ethernet connectors are used on most routers and Ethernet switches that connect devices to a network. To connect two cables, you need the standard male connector and a female version. You can also wire both sides with a standard RJ45 male connector and then add a female/female coupler.

A pluggable RJ45 connector from Phoenix Contact, male plug and female socket configurations.

Pros: Readily available components

Cons: Not watertight, not good in high-vibration areas, not ruggedized for industrial use

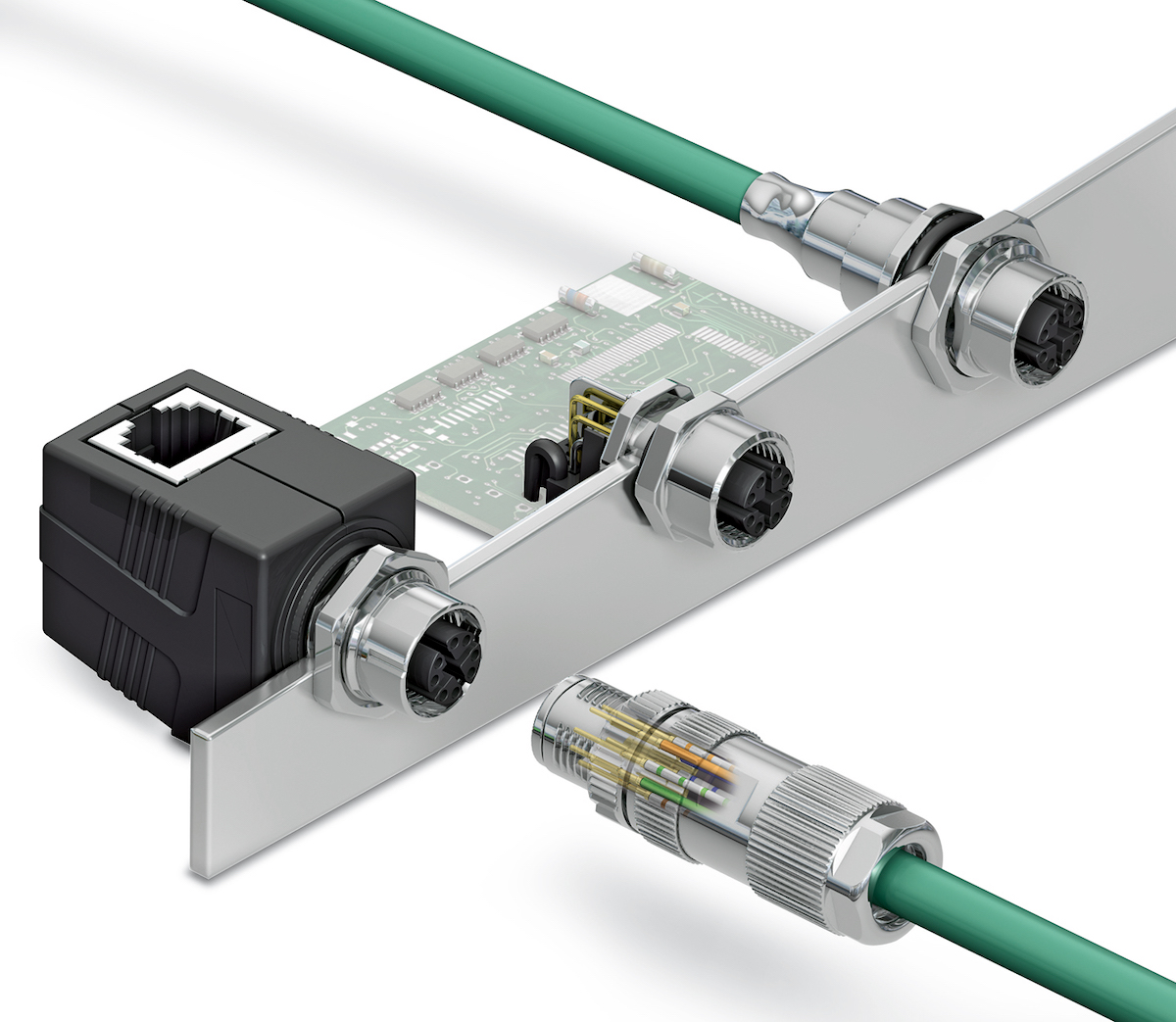

2. Put an industrial M12 connector on it.

For industrial wiring on the factory floor, the M12 connector has become the proven standard. Used in many vision systems, I/O blocks, and data loggers, this Industrial Ethernet connector maintains data integrity in wet, dusty, and high-vibration areas. It is also typically shielded for better protection against electromagnetic interference (EMI).

Industrial M12 connectors from Phoenix Contact

Pros: Robust, water-tight, secure locking

Cons: Female versions or couplers are not as readily available

3. Connect to a patch panel.

Often, a free-end cable first needs to be fed into a junction box or enclosure without a connector. This is because sealing glands on panel knockouts must be sized to seal the cable diameter and thus don’t allow enough clearance for a connector to pass through. One common method for connecting data cables inside an enclosure is to use a patch panel. Cut wire can be terminated using common methods like screw connections, push-in spring connections, or insulation displacement connection (IDC) terminals. Additionally, simple pass-through RJ45-to-RJ45 options are commonly available.

Pros: Small width, modular, DIN-rail-mounted, various wiring options

Cons: Requires additional enclosure and glands for sealing

4. Simply plug RJ45 connectors into an unmanaged Ethernet switch.

The cost of industrial switches has decreased greatly in the past decade, making them an affordable choice for connecting multiple Ethernet cables. They support standard functions such as data packet prioritization and are commonly referred to as the Ethernet wire nut. They also come in a ruggedized housing, are rated to a wide temperature range, and are available with DIN rail mounting options.

An unmanaged Ethernet switch from Phoenix Contact.

Pros: Best for connecting multiple free-end Ethernet cables. Mechanical port locks avoid unauthorized removal.

Cons: Requires additional enclosure and glands for sealing. Not cost-effective when only combining two cables.

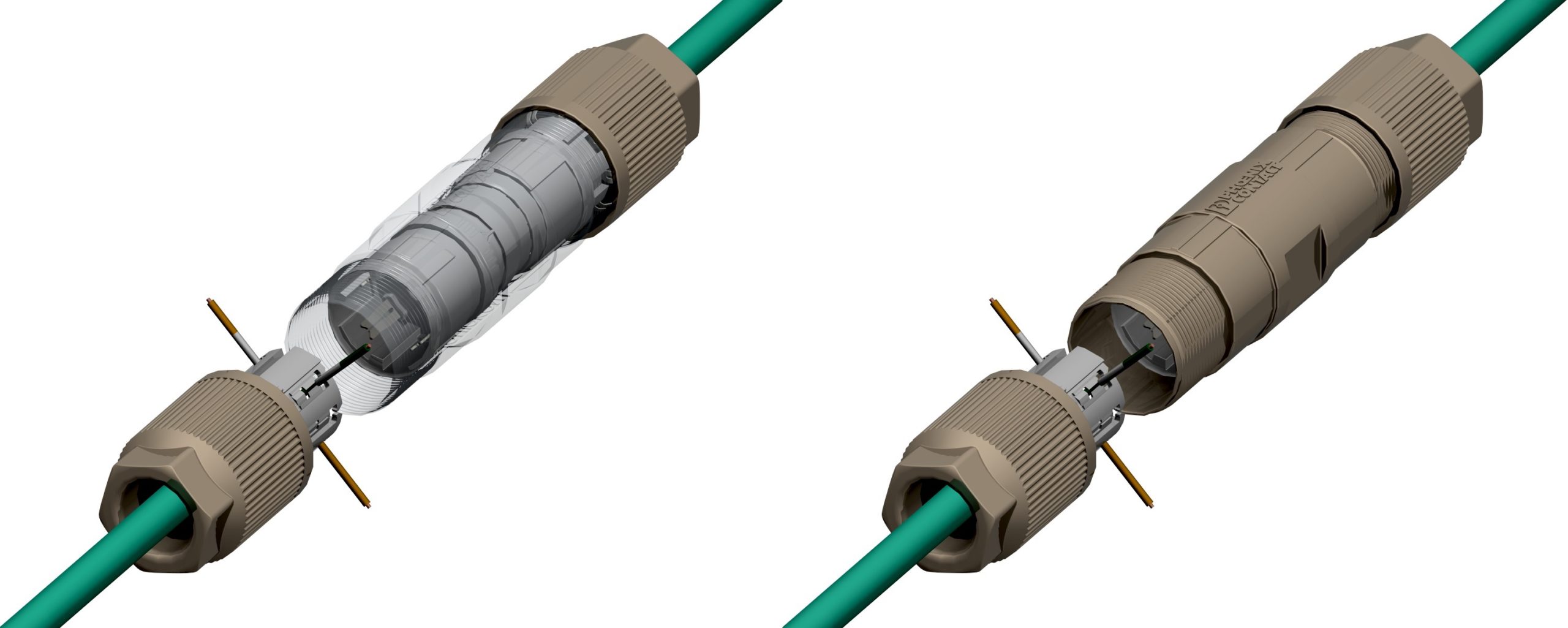

5. Use new IDC watertight inline cable splice connectors.

New developments in splice connectors make it easier to join two cables without the trade-offs or additional parts and labor common to other methods of connecting two Industrial Ethernet cables, and with only a single part. IDC technology is perfect for field installations because it doesn’t require wire stripping or any special tools, and can be up to 80% quicker to install than competing connector solutions. In addition, the small circular form factor of these connectors is designed to fit round cables naturally and can easily establish permanent shielded connections to ensure reliable data communication.

Pros: Fully shielded, reduced assembly time, only three components, wide cable OD and AWG range, perfect for simple on-site wiring

Cons: Not for plug-and-play

While each of these termination methods will connect two Industrial Ethernet cables, inline splice connectors offer a simple, practical, single-component solution that saves both time and money. This solution has successfully been used to solve the installation challenges of many applications. For example, they are particularly well-suited for:

- Maintenance Worker Repair: A damaged Ethernet cable can quickly shut down machine operation. If an installed cable is cut or damaged, these splices can enable quick on-site repairs, restoring operation in less than 15 minutes.

- Traffic Monitoring and Surveillance Installations: Direct-burial cables are often run underground and up into the camera’s pole. The UV-rated black camera cable then needs to tie into the underground run. These splices provide a compact and robust connection point between the two cables in the pole.

- Cable Extension: Rather than pulling a whole new cable when an Ethernet run needs to be extended, these splices allow the additional length needed to be added onto the existing run. Ethernet typically has a maximum length of 100m; so, if 75m are already installed, a 10m add-on splice is a much more cost-effective option than a new 85m run.

- New and Expanding Infrastructure: Industrial Ethernet cables are typically rated and ideal for railway applications. They are also commonly used to upgrade public transit vehicles and add smart building lighting systems. With watertight IDC cable splices, the options are endless for connecting Ethernet devices in even the most aggressive environments.

The unique approach to field-splicing that shielded, watertight IDC inline cable splices provide can improve installation process and reduce both downtime and labor and component costs. More than a simple junction, robust inline cable splice connectors create a permanent, shielded connection to ensure reliable data communication. They are one of the most effective solutions for connecting two Industrial Ethernet cables.

For more information, visit Phoenix Contact online or email authors Nate Owens and Sam Hartman.