It’s a Bird; It’s a Plane — No, it’s a UAV!

Electronic connectors play a critical role in the expanding world of unmanned vehicles and devices.

The electronic component industry has benefited over the years from the introduction of entirely new classes of products that created additional applications for separable connectors. In some cases, what has historically been a mechanical device is adapted to or replaced by electronics. Examples of this “electronification” process include the typewriter being made obsolete by the personal computer, engineering drawings being replaced by 3D CAD renderings, and the lighting and ignition circuits in automobiles being supplemented by multiple computers that manage everything from entertainment to engine exhaust.

The electronic component industry has benefited over the years from the introduction of entirely new classes of products that created additional applications for separable connectors. In some cases, what has historically been a mechanical device is adapted to or replaced by electronics. Examples of this “electronification” process include the typewriter being made obsolete by the personal computer, engineering drawings being replaced by 3D CAD renderings, and the lighting and ignition circuits in automobiles being supplemented by multiple computers that manage everything from entertainment to engine exhaust.

The connector industry has been a huge beneficiary of this process and has responded to the technical challenges by developing a constant stream of new interfaces that address the needs of these unique applications. In addition to standard lines of connectors, many of which have become high-volume commodity products, connector manufacturers have developed new interfaces that address specific application requirements including higher current, smaller size, higher pin counts, greater reliability, controlled impedance, EMI shielding, and resistance to rugged environments. Highly specialized connectors have been developed for specific applications that range from land grid array sockets with 1,000+ contacts to power connectors that are rated to 800+ amps.

Today, a new device category of unmanned aerial, land, and undersea vehicles is an emerging market that originated to serve military requirements but is now growing into a host of civilian applications.

Although the concept of unmanned or autonomously controlled vehicles dates back to the early 1900s, UAVs have experienced spectacular growth over the past 10 years. The Predator, one of the first military UAV platforms, was developed in 1994 and first deployed in Bosnia in 1995, primarily in surveillance missions. Its role changed in 2002 when it was outfitted with Hellfire missiles and became an effective seek-and-destroy weapon in Afghanistan. The roster of UAVs, along with the scope of their capabilities, has grown logarithmically due to their phenomenal success in disabling the leadership of Al-Qaeda in Afghanistan, Iraq, and Pakistan. The ability to swoop down on an enemy, undetected until the last moment, has enabled our military to take our soldiers out of harm’s way, a major step toward remote-controlled warfare. UAVs can operate at high or exceptionally low elevations and have enabled extended observation flights of up to 36 hours. The Defense Department reported that one in three aircraft in its arsenal is now unmanned.

Although the concept of unmanned or autonomously controlled vehicles dates back to the early 1900s, UAVs have experienced spectacular growth over the past 10 years. The Predator, one of the first military UAV platforms, was developed in 1994 and first deployed in Bosnia in 1995, primarily in surveillance missions. Its role changed in 2002 when it was outfitted with Hellfire missiles and became an effective seek-and-destroy weapon in Afghanistan. The roster of UAVs, along with the scope of their capabilities, has grown logarithmically due to their phenomenal success in disabling the leadership of Al-Qaeda in Afghanistan, Iraq, and Pakistan. The ability to swoop down on an enemy, undetected until the last moment, has enabled our military to take our soldiers out of harm’s way, a major step toward remote-controlled warfare. UAVs can operate at high or exceptionally low elevations and have enabled extended observation flights of up to 36 hours. The Defense Department reported that one in three aircraft in its arsenal is now unmanned.

Miniature UAVs, such as “throwbots,” can literally be tossed into a room, right themselves, and even climb stairs while performing video surveillance or bomb detection. Some of these may be considered expendable for use in a single mission. Others, such as the Predator, are expected to perform for many years. Components used in these devices must meet the highest level of durability possible.

Miniature UAVs, such as “throwbots,” can literally be tossed into a room, right themselves, and even climb stairs while performing video surveillance or bomb detection. Some of these may be considered expendable for use in a single mission. Others, such as the Predator, are expected to perform for many years. Components used in these devices must meet the highest level of durability possible.

A large arsenal of new unmanned, remotely controlled devices has been developed for specific tasks in recent years, including bomb detection and removal, surveillance, material transportation, and even rescue of injured soldiers.

A large arsenal of new unmanned, remotely controlled devices has been developed for specific tasks in recent years, including bomb detection and removal, surveillance, material transportation, and even rescue of injured soldiers.

In addition to the vehicle, a typical military UAV system consists of a ground control unit and satellite communications terminal. The UAV incorporates an extensive array of electronic systems that manage flight control, navigation, video reconnaissance, weapons management, target acquisition, and communications. All of these systems require absolute reliability in potentially harsh environments.

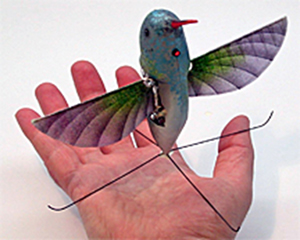

At the opposite end of the scale are “microbots” that measure a few inches in diameter and are designed to fly, crawl on the ground, or move on or under the sea to provide close-range and undectable video and audio. Recent demonstrations have proven the ability of position-aware microbot swarms to avoid collision and perform group tasks.

At the opposite end of the scale are “microbots” that measure a few inches in diameter and are designed to fly, crawl on the ground, or move on or under the sea to provide close-range and undectable video and audio. Recent demonstrations have proven the ability of position-aware microbot swarms to avoid collision and perform group tasks.

Autonomous vehicles are another class of devices that have begun to enter the market. The US Army recently approved the Lockheed Martin Squad Mission Support System (SMSS), which is an autonomous truck with a range of 125 miles that is capable of transporting 1,000 pounds of equipment over rugged terrain. These driverless vehicles navigate to programmed destinations and have the ability to recognize established roads as well as navigate around obstacles.

Work also continues on autonomous killer drones that carry lethal weapons, although there are serious ethical and legal issues that must be resolved before they can be deployed.

Work also continues on autonomous killer drones that carry lethal weapons, although there are serious ethical and legal issues that must be resolved before they can be deployed.

Remotely piloted aerial and land vehicles have also caught the attention of civilian authorities. Small UAVs are cost-effective alternatives to deploying a full-size helicopter for surveillance by police. Not only is the platform much less expensive to purchase, but it can cost as little as $30 per hour to operate. Firemen are able to survey the condition of a building or forest fire to determine the most effective attack. Drones have been used to dust crops, create maps, and cover news events, as well as monitor transmission lines, flood conditions, livestock, and wildlife. Already dozens of law enforcement agencies have obtained FAA approval for operating domestic UAVs.

Remotely piloted aerial and land vehicles have also caught the attention of civilian authorities. Small UAVs are cost-effective alternatives to deploying a full-size helicopter for surveillance by police. Not only is the platform much less expensive to purchase, but it can cost as little as $30 per hour to operate. Firemen are able to survey the condition of a building or forest fire to determine the most effective attack. Drones have been used to dust crops, create maps, and cover news events, as well as monitor transmission lines, flood conditions, livestock, and wildlife. Already dozens of law enforcement agencies have obtained FAA approval for operating domestic UAVs.

Many of these surveillance platforms have been used by the government to patrol our borders to fight drug trafficking and illegal immigration. Other civilian robots investigate potential bombs and search earthquake-damaged buildings for survivors. Remote-controlled robots were sent into the tsunami-ravaged nuclear reactors in Japan, where radiation levels would be lethal to personnel. Future applications include the possibility of unmanned autonomous commercial aircraft to ferry cargo and even passengers between airports.

Fleets of domestic drones have raised a number of concerns including privacy issues and fears of collision with passenger planes. The FAA is in the process of devising new regulations and appears to be moving toward allowing drones unlimited access to civilian airspace. The trend is clearly for more of these devices to be deployed. More than 50 companies are said to be working on domestic drones, as the market potential far exceeds military forecasts.

Unlike consumer remote-controlled toys, unmanned vehicles in military and commercial applications require highly reliable connectors and cable assemblies that transmit everything from DC power to high-speed video signals. Connectors must be small and lightweight, with the ability to survive shock, continuous vibration, and exposure to moisture, while operating in a wide range of ambient temperatures. They must provide a fail-safe connection that is often serviced by untrained personnel in field conditions. Connector types vary from standard and hybrid circular military styles such as MIL-DTL-38999 to rectangular MIL-C 24308 types.

Unlike consumer remote-controlled toys, unmanned vehicles in military and commercial applications require highly reliable connectors and cable assemblies that transmit everything from DC power to high-speed video signals. Connectors must be small and lightweight, with the ability to survive shock, continuous vibration, and exposure to moisture, while operating in a wide range of ambient temperatures. They must provide a fail-safe connection that is often serviced by untrained personnel in field conditions. Connector types vary from standard and hybrid circular military styles such as MIL-DTL-38999 to rectangular MIL-C 24308 types.

Connectors that feature environmental and hermetic sealing, as well as EMI filters, are vital in these applications to protect critical circuits. Their ability to maintain tightly controlled impedance is important in high-speed circuits. Micro and nano connectors address concerns for size and weight, and in some cases highly specialized connectors that feature aluminum alloy and composite shells are being marketed to specifically address UAV applications. Fiber optic connectors also offer major advantages with their reduced size, lighter weight, and extended bandwidth, with the added bonus of EMI resistance. Ruggedized connectors that support standard interface protocols, including USB, PCIe, and 10Gb Ethernet, are also in demand.

Connectors that feature environmental and hermetic sealing, as well as EMI filters, are vital in these applications to protect critical circuits. Their ability to maintain tightly controlled impedance is important in high-speed circuits. Micro and nano connectors address concerns for size and weight, and in some cases highly specialized connectors that feature aluminum alloy and composite shells are being marketed to specifically address UAV applications. Fiber optic connectors also offer major advantages with their reduced size, lighter weight, and extended bandwidth, with the added bonus of EMI resistance. Ruggedized connectors that support standard interface protocols, including USB, PCIe, and 10Gb Ethernet, are also in demand.

In addition to the many interfaces located in the unmanned vehicle, ground-based control and maintenance equipment also provides new opportunities for connector manufacturers in this market segment.

In addition to the many interfaces located in the unmanned vehicle, ground-based control and maintenance equipment also provides new opportunities for connector manufacturers in this market segment.

Suppliers such as Fischer, a company that has historically focused on connectors used in high reliability medical equipment, have adapted product lines for UAV applications. Other broad line suppliers, such as Amphenol Pcd, Harwin, Hypertronics, Molex, and TE Connectivity, are marketing appropriate connector types to address applications in this high value connector segment where durability and reliability is the top priority.

Current estimates indicate that the United States military has a stable of more than 7,000 unmanned air, ground, and undersea devices, with many more on order. The aerospace industry forecasts a worldwide deployment of nearly 30,000 UAVs by 2018, half of which are expected within the United States. With the long-term objective to reduce the number of soldiers on the battlefield, these high-tech devices are more cost-effective and more politically acceptable. Although overall defense spending is expected to drop 5 to 10% over the next 18 months, the percentage of the remaining budget allocated to drones is expected to grow.

The civilian market could be many times the size of the military segment, with more than 19,000 domestic law enforcement agencies potentially looking at this technology.

Some estimates put the global value of spending for unmanned aerial vehicles at $5.9 billion, with the expectation that spending will double over the next 10 years. Connector content will represent a significant percentage of that total value, making this market a very attractive growth segment. Once again, advances in technology are opening new product categories and providing expanded opportunities to the electronic connector industry.

- Optics Outpace Copper at OFC 2024 - April 16, 2024

- Digital Lighting Enhances your Theatrical Experience - March 5, 2024

- DesignCon 2024 in Review - February 13, 2024