Problem Solved – Thinking Inside the Box (and Rack)

Problem Solved – Thinking Inside the Box (and Rack)

Building enterprise computing systems and configuring the data centers they inhabit present a number of challenges. Space ranks at the top of the list; more and more performance must be wrung from the same volume as the previous product generation. Meanwhile, additional equipment needs to be squeezed into the data center’s existing footprint. Cables and cable assemblies for internal and external applications can make this challenge more difficult by requiring a large-volume pathway for routing.

Building enterprise computing systems and configuring the data centers they inhabit present a number of challenges. Space ranks at the top of the list; more and more performance must be wrung from the same volume as the previous product generation. Meanwhile, additional equipment needs to be squeezed into the data center’s existing footprint. Cables and cable assemblies for internal and external applications can make this challenge more difficult by requiring a large-volume pathway for routing.

Passive copper cables remain a cost-effective option for routing I/O in high-performance enterprise systems and for networking applications with reaches of 10 meters or less. However, conventional copper cabling can consume precious real estate and contribute to congestion inside and outside the box. Internally, cable congestion can restrict critical airflow around the electronic components and block heat sinks. Externally, cables can eat up precious space in the rack. In addition to their bulk, most high-speed cables require a generous bend radius, demanding even more space.

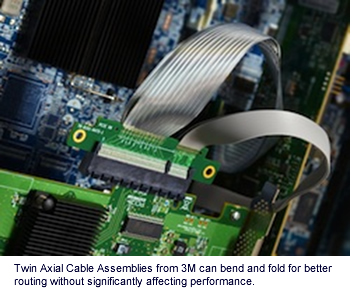

In response to acute space constraints, 3M set out to design a thinner, more routable high-speed twin axial cable. That effort resulted in the development of a flat, foldable twin axial cable. The cable’s construction is fundamentally different than conventional wrapped twin axial cable. It provides high signal integrity over large distances, and has the ability to bend and fold without significantly affecting performance. Cable assemblies based on the cable are currently being used for and designed into internal and external applications to speeds as high as 14 Gb/s per channel and potentially much higher, depending on cable length and configuration.

A major barrier to decreasing cable assembly bulk and increasing routability has been the shielding construction. Shielding, of course, is necessary to maintain signal integrity in high-speed data cables. In conventional twin axial constructions, shielding is typically wrapped spirally around the insulated wire pairs. The shielding layer is then overwrapped with another film layer to provide support and retain the primary shield wrap. In a bundle of eight such pairs, the final cable is typically 4 mm to 8 mm thick (depending on the wire gauge and the material used to contain the bundle). While wrapped-shield cables offer some limited ability to bend around corners, designers must be careful not to bend the cables too much because the shielding and overwrap materials can distort the precise cable geometry needed to maintain impedance control, which can degrade signal performance. Moreover, the wrapped shield, with repeated breaks in the shield along the cable length, can produce an unwanted resonance effect, evident at certain frequencies.

The flat, foldable twin axial cable takes a different approach. It combines very low bend radius with high performance. This is achieved by using a longitudinal shield structure with a signal response that is highly tolerant of decreased bend radii. With this design, bending and folding the cable, even in multiple places, does not significantly impact its performance. Tests show that each fold (180° fold at 1 mm bend radius) impacts impedance at the fold location by approximately 0.5 ohms (70 ps 20/80% rise time), which is well within the tightest impedance specification. In many current applications, the cable is folded in at least four or more locations. An even greater fold count can be achieved without adversely affecting the cable or cable assembly’s ability to meet the given performance requirement.

At only 0.88 mm thick for a single ribbon of 30 AWG (American Wire Gauge) cable (two ribbons stacked or side-by-side are needed for an 8-pair cable), this flat, foldable twin axial cable is significantly slimmer than its wrapped-shield predecessors, yet it can outperform them. Up to at least 40 GHz, according to tests conducted at 3M, the cable is free from the large signal loss over a certain frequency range (resonance) that is common in wrapped-shield twin axial cable. This means that the cable is suitable for current and emerging high-speed serial transmission standards, such as SAS 2.1, PCI Express, Ethernet, Infiniband, SFP+, QSFP/QSFP+, and others. The cable is also low skew, and the ribbon construction allows users to further control skew that sometimes occurs when managing discrete, individual twin axial pairs, which is especially important at speeds above 10 Gb/s.

For internal applications, the flat, foldable twin axial cable’s tight bend radius and low profile opens up entirely new options for routing cable. The cable can be run along cabinet walls and bent flush into corners. It can snake between processors, heat sinks, and fans, freeing up valuable space in the mechanical design of the unit for components or airflow. Highly conformable compared to round cable, the cable can be placed out of the way of airflow. Therefore, it can potentially reduce the cost, complexity, and power consumption of cooling the system.

For external applications, the cable’s ability to fold allows for higher density racks and space savings. A typical round copper cable can consume several inches as it is bent to turn a corner, while a flat foldable cable can use less than half an inch to bend. The combined space savings multiplied over many racks in a data center can be very significant.[hr]

By Douglas Gundel, Lead Product Development Engineer, 3M Electronic Solution Division