The World is Flat: FFCs Define Future Applications

Flat flexible cables are sliding into places other cables dare not go and help keep devices cool, light, and fast.

In the realm of cables, the usual suspects are round. A cylindrical package is a logical design to surround a centrally positioned conductor within insulation or to encase a bundle of fibers. However, that logic dissolved in the push towards high-density computing applications such as small personal electronics. In these ever-shrinking form factors, cables need to be able to slip into tight spaces. Flexible flat cable (FFC) fits the bill, as its super-low profile allows it to easily fit into tight spaces. It can bend or even fold and typically is lighter in weight than its round counterparts, making it a good choice for portable devices or automotive and aerospace equipment, where weight savings is critical.

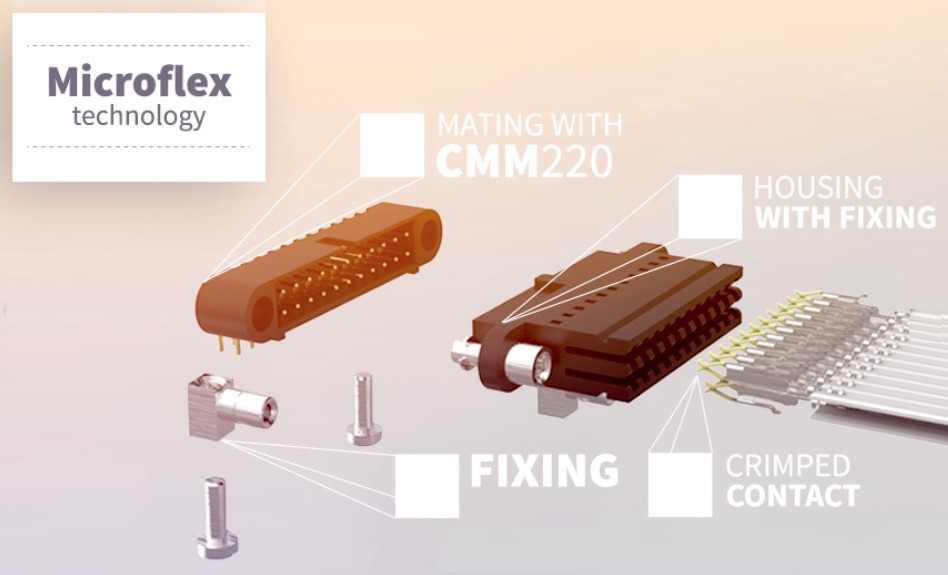

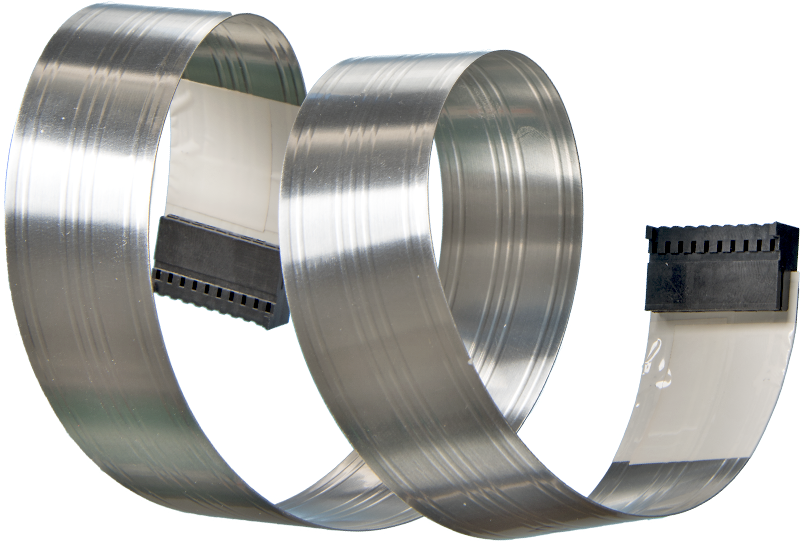

Nicomatic FFC Cable

FFC, a recent variation of the ribbon cable that became prolific in 1960s, consists of a micro-thin, tape-like length of flexible plastic, film, polymeric, or engineered rubber material with metal (typically copper) wire conductors embedded in parallel along its base. The distance between each of those conductors is defined as its pitch, and FFC cables are available in pitches that typically range from 0.5mm to 2.00mm and beyond. This pitch enables each wire to be individually shielded from other wires and interference. Spreading out the conducting wires also helps disperse heat. The wire gauges available for FFC have expanded to a span of 4 to 44 AWG.

Nicomatic Microflex Technology

The encasement material for those wires can be specified to meet unique application environments, and treatments are available for thermal protection, chemical exposure resistance, and other qualities. In flexible printed cable (FPC), a related technology, the circuitry is printed or embedded directly onto the plastic substrate, essentially enabling a cable to function as a flexible printed circuit board (PCB).

Although FFC first found widespread use in consumer and computing applications, it is rapidly becoming a top choice in other markets. FFC is now used in many portable medical devices, and as industrial and transportation equipment evolves to demand greater connectivity, this cable type is finding a place in larger applications. The explosive growth in electronic content in automobiles, for instance, has created new opportunities for FFC and FPC cables and connectors in lighting, entertainment, navigation, and safety systems. The rollout of Industry 4.0 and 5G will depend heavily on these versatile and powerful cable options.

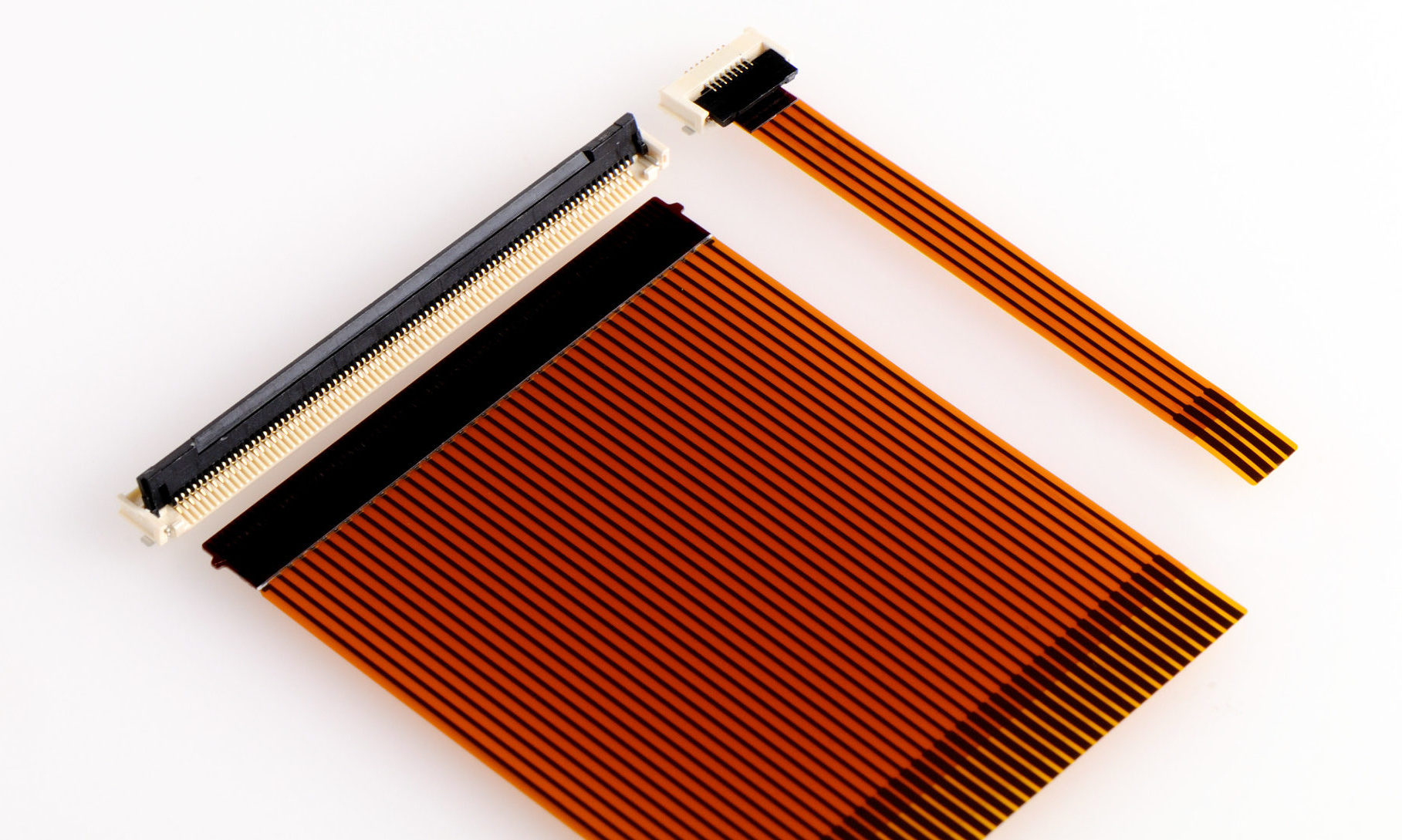

EVAFLEX Connectors by I-PEX coordinate well with FFC products.

“FPC connectors will be integral in the deployment of mobile 5G. The future requirements of 5G are forcing FPC suppliers to ‘catch up’ to PCB technology to support millimeter wave frequencies efficiently,” said Travis Amrine, global industry marketing manager, I-PEX Connectors. “We innovate with the 5G chipset market leaders and their FPC partners to enable current and future designs.”

I-PEX Connector’s NOVASTACK 35-HDP Shielded Board-to-Board FPC connector

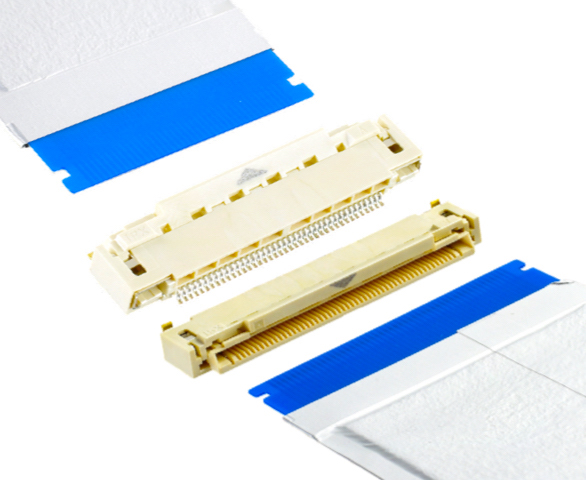

A variety of interconnect products provide termination options for FPC and FFC cabling. The I-PEX MINIFLEX FPC/FFC connectors, commonly referred to as zero-insertion-force (ZIF) or low-insertion-force (LIF) connectors, offer some of the smallest pin pitch ranges on the market, extending from 0.5mm to 0.175mm. Connector height profiles range from 2.5mm to 0.55mm. For applications that require higher FPC retention force, secure connections can be ensured with an additional mechanical lock option with an FPC cut-out lock feature. I-PEX Connector’s EVAFLEX FPC/FFC connectors have an auto-locking feature that makes them more robust and durable than traditional FPC/FFC connectors. These connectors also include EMI shielding, support high-data-rate transmission, and can endure higher levels of shock and vibration than most FFC/FPC connectors. In addition, its NOVASTACK family of board-to-board and board-to-flex (FPC) connectors are designed to handle high-speed and high-frequency signals and are available in fully shielded and unshielded versions with a 0.35mm pitch and a 0.7mm mated height (without FPC).

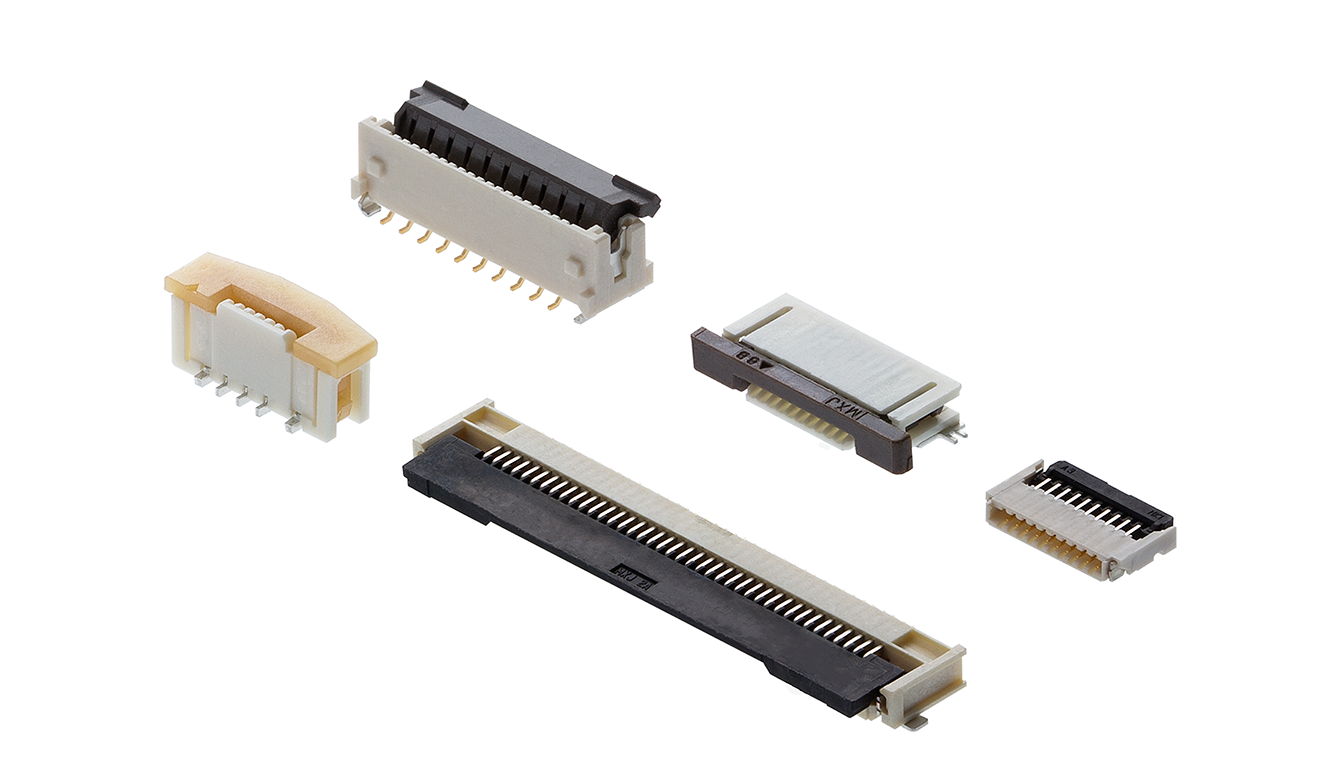

Molex FFC and FPC connector and cable products

Molex makes a broad selection of FFC and FPC connectors with dual, bottom, and top contact positions in an assortment of circuit sizes and cable style choices to create additional design flexibility. “The digital transformation of our global society is driving market demands for increasingly smaller, more reliable connections. In anticipation of these complex design challenges, Molex is continually designing and developing lower-profile and higher-density interconnects,” said Mike Higashikawa, business development manager, Molex Micro Solutions.

Molex Easy-On FFC and FPC Connectors

The company’s Easy-On FFC/FPC product line of connectors offer pitches as tight as 0.20mm and provide ideal solutions for space-constrained packaging applications like gaming devices, drones, smartphones, wearable devices, automotive interior systems, and medical devices. With ZIF, non-ZIF, slider, flip actuator, and FPC-to-board styles, and a variety of circuit options, this combination of features makes it easy to properly mate the connector while providing reliable, high-retention force needed to withstand exposure to shock and vibration.

At electronica 2018, Nicomatic displayed its FFC V Shield cable, a flexible shielded solution for harsh environment applications. This cable provides protection from electromagnetic and radio frequency interference (EMI/RFI) and electrostatic discharge (ESD), which makes it suitable for applications where high-flexibility cable and data protection are crucial. The FFC V Shield is lightweight and durable with a flex life of 15 million cycles and a bend radius of 63.5mm. Nicomatic also makes an FFC cable product used in jumpers that consists of two flat copper conductors laminated between two layers of polyester/adhesive insulation. The company says these jumpers provide a better retention compared to FFCs used with ZIF/LIF connectors, thanks to a large selection of contacts and housing choices. The best contact resistance, together with a high mechanical force, provide greater overall system reliability, which translates to a longer life for the end product.

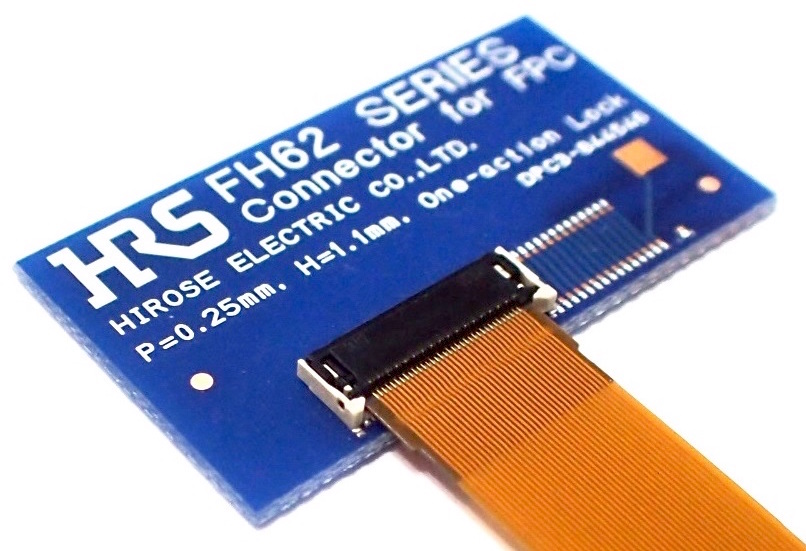

Hirose FH62 Series FFC

Hirose also offers FFC/FPC connectors that are well suited to robotic or hand assembly. The FH62/FH63 Series feature one-action locking and mating can be confirmed with an image sensor. The FH62’s low height and narrow pitch make it a good choice for portable devices, while the FH63 is heat-resistant up to 105°C and features a two-point contact structure. These connectors are ideal for televisions, appliances, automotive applications, and medical equipment.

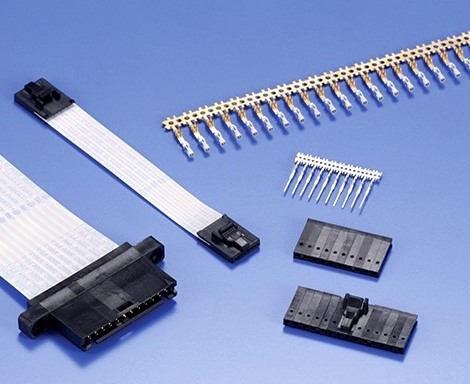

TE Connectivity’s offerings for FFC and FPC connectors include a variety of high-density wire-to-board (WTB) and wire-to-wire (WTW) connectors designed for automated assembly. The family is composed of WTB products on 2.54mm and 1.27mm centerlines and WTW products on 2.54mm centerlines. Receptacle housings not only mate with the pin housings, but also with an array of PCB headers from other TE product families, including AMPMODU and AMP-LATCH connectors.

TE Connectivity FFC Products

As the market trends towards miniaturization, FPC connectors have been developed to meet the challenges of this expanding market, which demands smaller centerline or pitch spacing, lower profile heights, and lighter interconnect solutions. TE’s Connectivity’s FPC solutions use an actuator to secure the cable termination, don’t require any specialized machine tooling, are available in centerline spacings spanning 0.25mm to 1.25mm, and have a lightweight, low-profile package.

Many other connector companies offer FFC and FPC products as well. AirBorn Flexible Circuits makes printed circuitry in single-sided, double-sided, multi-layer, rigid-flex and sculptured flex variations, as well as built-in contacts. ACES Connectors‘ line of FFC/FPC connectors come in various pitch options and include features to meet a wide variety of space and usage needs for applications in all markets, such as high-speed transmission for 10Gb/s, good retention with latch features, and EMI prevention with patented ground design.

These versatile, powerful cables and coordinating connectors have helped make possible today’s portable electronic devices. Future innovations undoubtedly will also rely on flat flexible cable to get into tight situations.

Like this article? Check out our other Connector and Cable Basics, New Technology, and High-Speed Connectivity articles, our 2019 Article Archive, and our Datacom/Telecom Market Page.

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024