M12 Connector Types, Uses & Applications

Rugged and durable M12 connectors have a long history, but connected industrial technologies have inspired new modifications, improvements, and utility.

Although M12 connectors have been in widespread use for decades — long before the Internet of Industrial Things (IIoT) or Industry 4.0 was even a concept — they have recently become the preferred connector for Industrial Ethernet. Designers and original equipment manufacturers (OEMs) are incorporating M12 connectors into new machines as industrial environments become increasingly connected. They are also using these connectors to update existing infrastructure. With backwards compatibility, using M12s to replace older and less robust technology is relatively simple and cost-effective.

On the device side, they are used for data transmission, pulling data from devices and transmitting it to the application, where data is aggregated to provide information to the user. M12 connectors also make the connections between programmable logic controllers (PLCs), sensors, input/output (I/O) blocks, and wireless access points (WAPs) and can transmit high levels of power for extended periods of time in applications such as alternating current (AC) motors and drives, motor control switches, and low-voltage applications like fieldbus Ethernet components and network devices.

M12 technology continues to evolve as the applications they serve become more connected. Manufacturers of M12 connectors are adding new features to meet the needs of the robotics, automation, food and beverage, alternative energy, transportation, and cellular communication industries. The flexibility and customization potential for these versatile and powerful connectors helps make them an enduring choice for industrial environments.

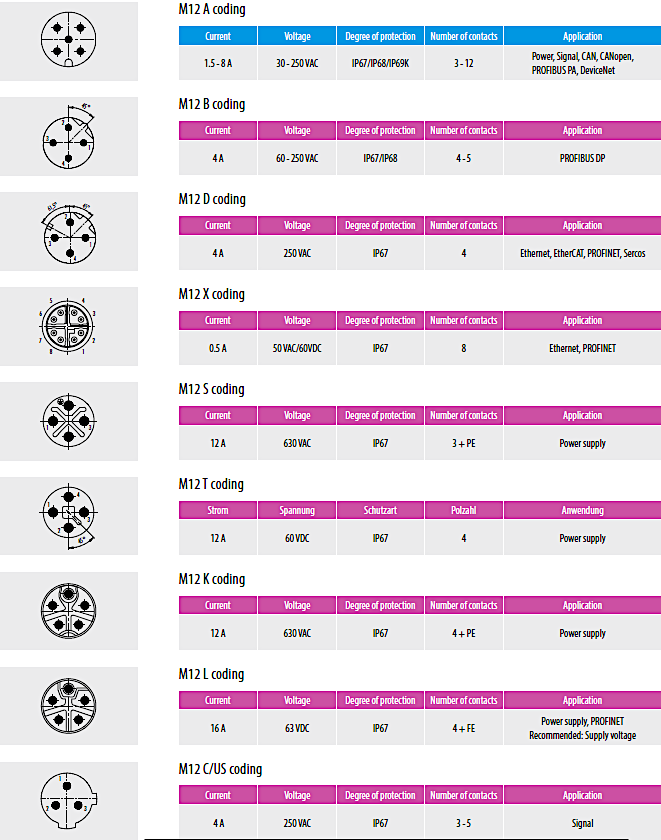

M12 Codings, Pins, and Coupling Systems

M12 connectors are available in a wide variety of configurations that enable designers to specify unique pin layouts, locking features, and coding features to suit the needs of a specific application.

Coding: On the plant floor or in the field, users must be able to disconnect existing connectors for maintenance or replacement and install new connectors quickly, especially in applications where connections must remain dust- and/or water-tight. M12 connectors are easily installable and clearly coded to reduce the chance of accidental mismating.

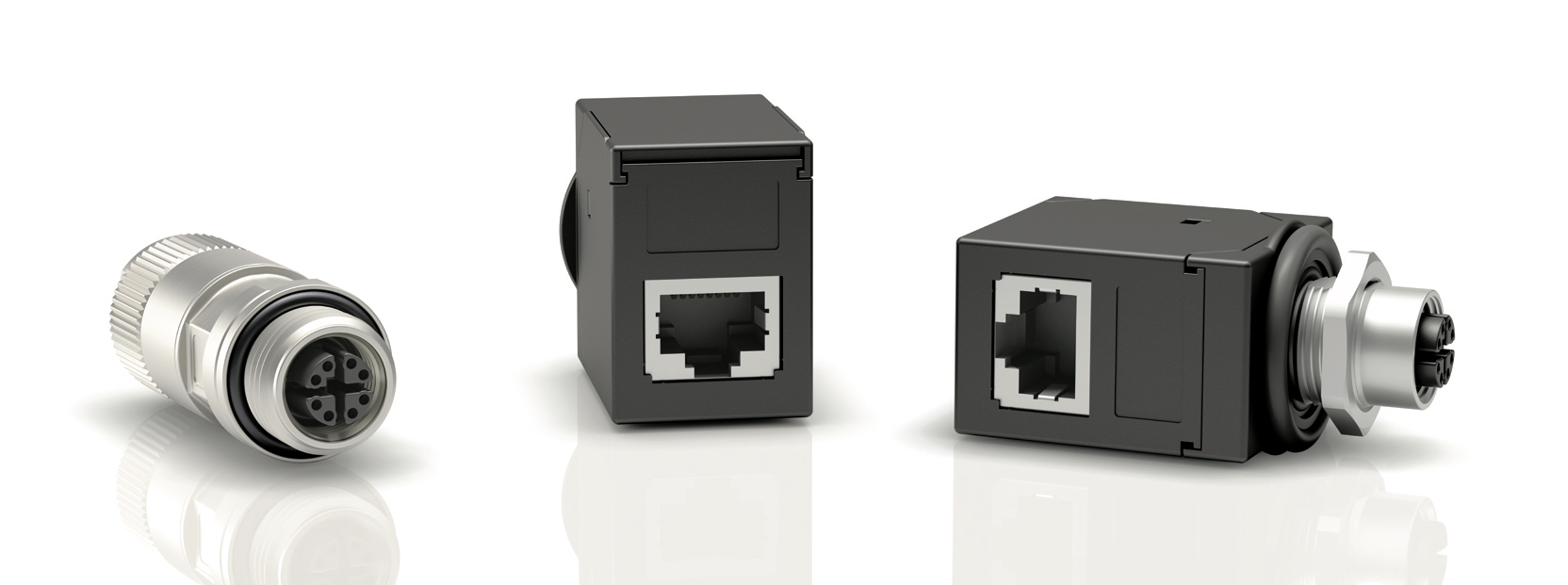

As applications require higher-speed connections, X-coded connectors like these M12 X-coded female connectors from binder will likely replace D-coded connectors.

M12 coding for signal and data transmission:

- A-coded for sensors and DC power

- B-coded for PROFIBUS

- D-coded for 100Mbit Ethernet and Profinet

- X-coded for 10Gbit Ethernet (10GbE)

M12 coding for power supplies:

- S-Coded and K-Coded connectors are designed for AC power supplies up to 630V/16 A. An ideal power connector for applications such as AC motor and drives, motor control switches, and frequency inverters.

- T-Coded and L-Coded connectors are designed for DC power supplies up to 63V DC/16 A. An ideal power connector for low-voltage applications such as DC motor and drives, fieldbus Ethernet components, network devices, and LED lighting fixtures.

M12-L DC power supply connectors from binder are PROFINET-compliant and field-wireable.

Pins: M12 connectors are available with 3, 4, 5, 8, or 12 pins. The ideal pin-count depends on the application. For example, most sensors and power applications use three or four pins, while PROFINET and Ethernet use 4 and 8 pins, and 12 pins are for signal requirements.

Coupling Systems: There are three basic types of coupling systems for M12 connectors:

- Push-Pull: Mates easily and securely with an audible click to indicate that a proper connection has been established.

- Threaded: Provides high resistance against vibration.

- Bayonet: Uses pins on the receptacle and ramps on the plug to enable quick mating and unmating.

Additional M12 Features and Options

A connector or cable assembly choice for a specific application can be further customized by selecting application-specific options, including:

- Gender: male, female, hermaphroditic

- Termination Style: crimp, screw, clamp, or IDT (Insulation Displacement Termination)

- Housing Material: plastic, metal, or stainless steel

- Contact Plating: gold, tin, and Optalloy

- Environmental Protection: IP67, IP68, or IP69K

- Cable Length

- Cable Jacket: PUR or PVC

- Mounting Style: Panel-mount or field-attachable

- Rated Voltage

- Rated Current

Codings, pin-counts, and applications for M12 connectors

Rugged and Reliable Performance

M12 connectors are ideal for industrial environments in part because they offer superior performance in harsh conditions. M12 connectors offer a minimum of IP67-rated environmental protection against dust and water and also protect against impact, vibration, UV exposure, and temperature cycling. For the most demanding applications, such as those subject to frequent washdowns, they are also available with IP68 and IP69K sealing.

M12 A-coded connectors from binder are IP69K-rated, as well as Ecolab and FDA certified, making them ideal for harsh washdown applications in the food and beverage and chemical industries.

Mating cycle ratings are also an important consideration for machine builders choosing a connector for their application. Connector mating cycles are determined by the properties of the contact and plating materials used, as well as the thickness of the plating. Cheaper connectors, such as tin-plated copper alloy contacts, will not perform as well as those made with corrosion-resistant materials, such as gold-plated beryllium copper contacts, which are typically rated for more than 100 mating cycles.

EMI Shielding

Hard-wired M12 connections also offer some advantages over wireless connections, including the intrinsic security of physical connections and protection from interference, which is especially critical in IIoT-enabled factories filled with electromagnetic interference (EMI), such as radio frequency interference (RFI). Unseen and unheard by people, this electronic noise pollution frequently interferes with high-precision sensors already taxed by the physical noise and vibrations of a busy factory floor.

Compact Size

In addition to high signal integrity, Industry 4.0 applications demand ever more compact components and connectivity solutions, even as power and data transmission needs grow. Increasingly smaller devices and sensors are transmitting more data, which requires more connection points and means that connectors must deliver the same — if not greater — power density in a smaller footprint.

Originally designed to reduce the size of the original 7/8” standard sensor connectors, M12 connectors have an outside diameter of just 12mm. This small footprint makes M12s well suited for applications with little available space, including automation control systems, telemetry modules, compact LED lighting fixtures, and value actuators.

M12 connectors can transmit impressive amounts of data and power in rugged industrial environments and feature several critical features that enhance ruggedness, reduce interference, and enable flexibility. As such, they are sure to remain essential components as Industry 4.0 applications continue to expand and mature.

Like this article? Check out our other Connection Basics, M12, and Harsh Environment articles, our Industrial and Sensors & Antennas Market Pages, and our 2020 and 2019 Article Archives.

- M12 Connector Types, Uses & Applications - June 9, 2020