How to Source Connectors and Cabling for Industrial Applications

Harsh operating conditions and challenging installation scenarios make it important to specify rugged, reliable, and application-specific interconnects for industrial equipment.

Industrial Connectors

The extreme temperatures and humidity often present in industrial settings place considerable strain on electronic components and can cause equipment to malfunction. Interconnects used in industrial equipment and systems are also subjected to shocks and vibrational forces, and can also be at risk of liquid ingress, as components are sometimes situated on the exterior of equipment with direct exposure to harsh conditions. In addition to the challenging operating conditions, torsion forces, mechanical strain, and ongoing mating/un-mating activity that falls under typical use for industrial equipment can be detrimental to connector performance. Therefore, specifying rugged connectors and cabling for industrial applications involves careful consideration and appropriate test procedures to identify components that can withstand the conditions and deliver reliable performance.

Essential sourcing criteria

High temperatures are often a concern for connectors used in industrial equipment. Manufacturing facilities, energy installations, mining operations, and other industrial applications can be high heat operating environments, and the processes being carried out by equipment can also generate large quantities of heat. Connectors that support appropriate operational temperatures should always be sourced. EIA-364-32C Condition III testing can validate the ability of interconnect components to cope with extreme temperatures. To meet this standard, connectors are put through thermal cycles ranging from -55 °C to +125 °C for a total of 10 times in succession.

Connectors must also be highly resilient to the effects of vibrations, as most industrial settings include drives and motors that are running continuously. EIA-364-28D Condition IV tests can be used to assess how well connectors cope with vibrations. During this test procedure, units are subjected to vibrational frequencies cycling from 10Hz to 2000Hz, with a 1.52 mm vibrational amplitude, to make certain that connectors can perform reliably without interruptions to the electrical connection. This testing is conducted over a 12-hour period, with four hours being assigned to each of the different directional axes.

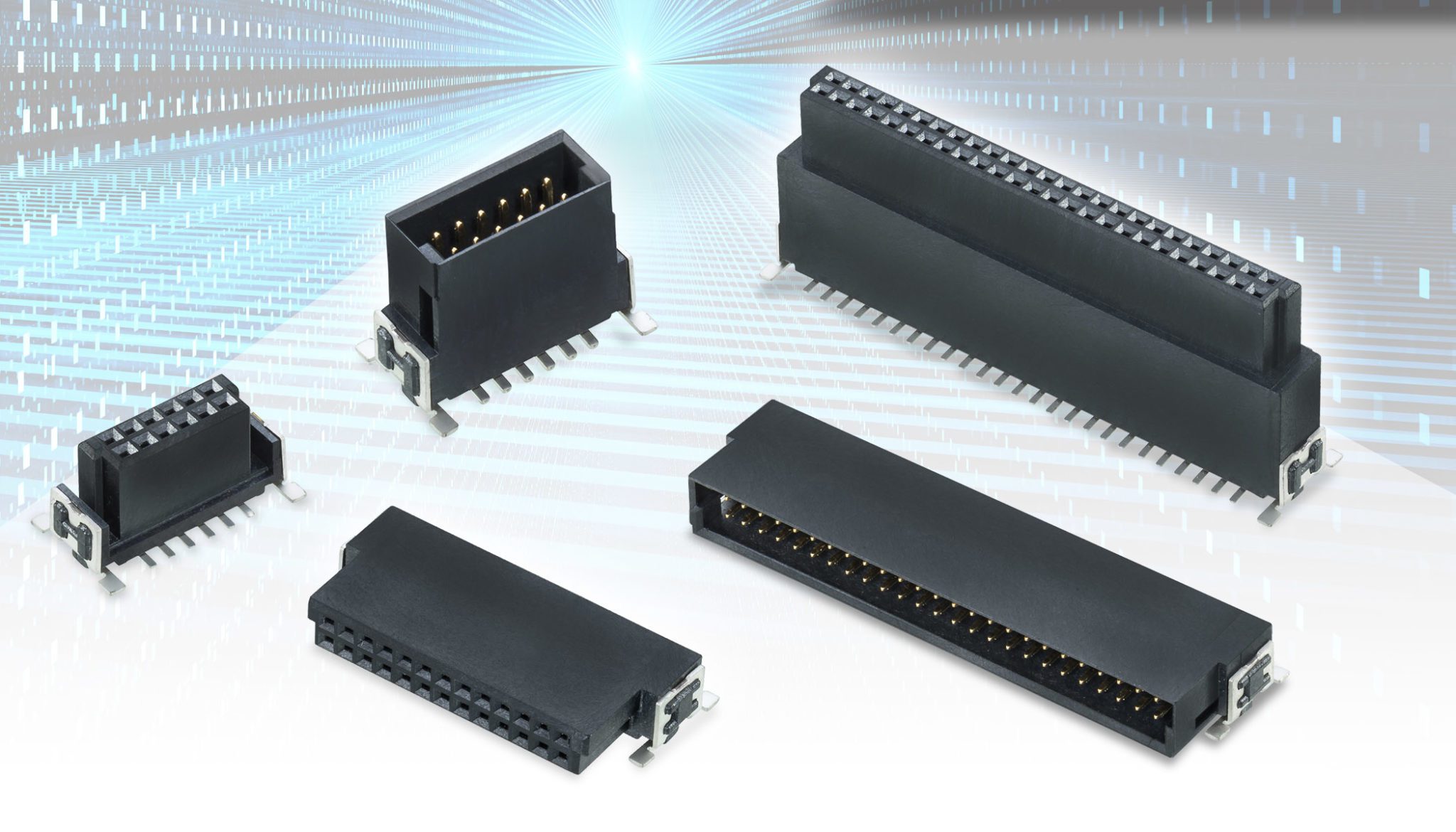

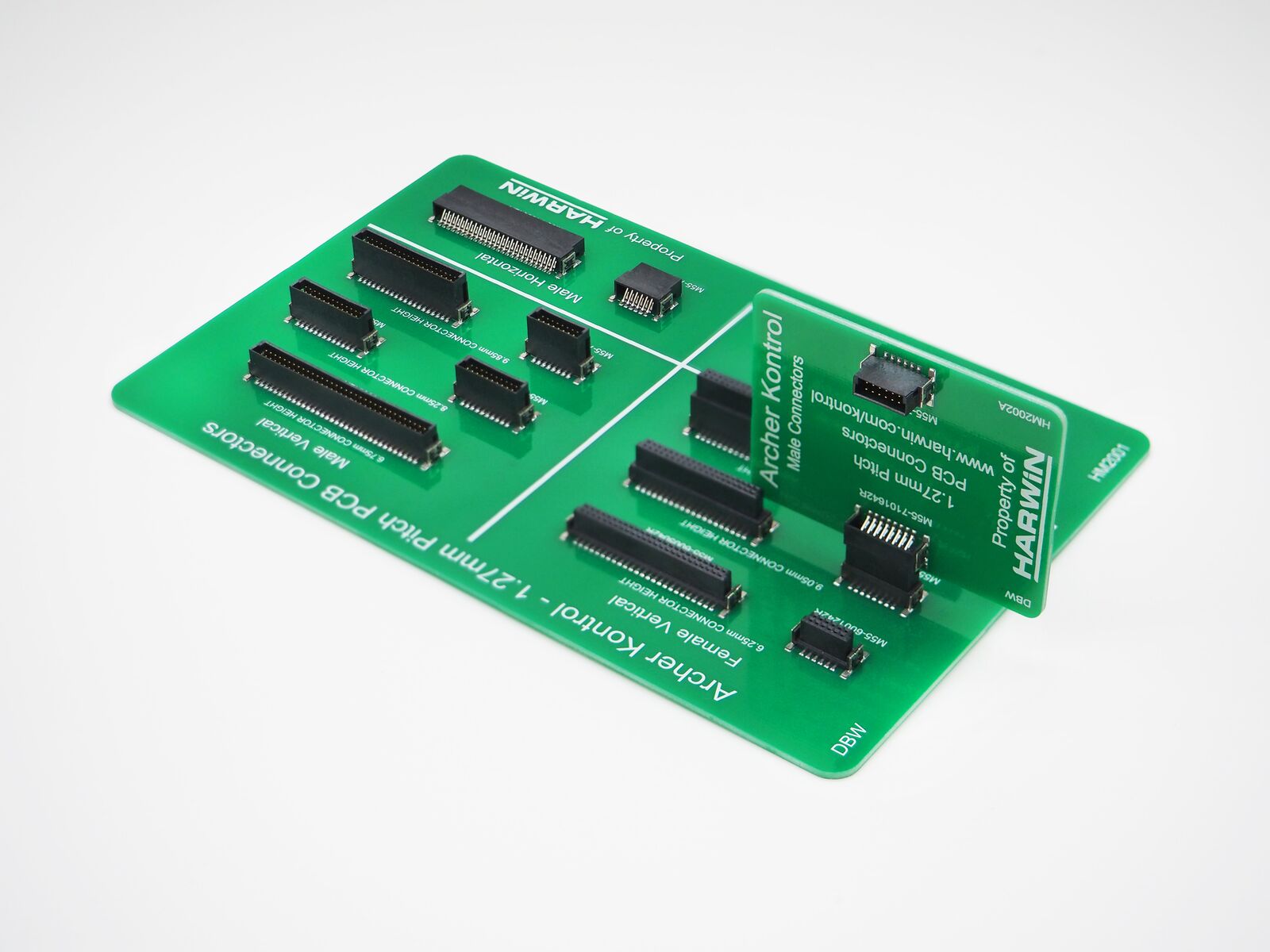

Harwin’s Archer Kontrol connectors can handle temperatures of up to 125 °C and meet EIA-364-32C Condition III thermal shock requirements and EIA-364-28D Condition IV vibration standards. An insulation resistance of >1000MΩ prevents flashover and a retention force of at least 3.9N per contact and a 500-cycle mating durability ensures long-term operational integrity.

Other mechanical stresses include the potential for cables to be pulled out and disconnected by the forces present. To prevent this from happening, some form of strain relief can be incorporated into the cable assembly. Using connectors with SMT hold-downs increases the surface area that the assembly has in contact with the PCB, allowing the connectors to withstand greater pulling forces. When additional strain relief is needed on a cable assembly, backpotting may be the best approach. Here, an epoxy resin compound is applied to the rear of the connector to better secure the wires. If repetitive movements are being made, or when there is limited space, using flexible printed circuits (FPCs) may be preferable to conventional cabling. FPCs have a much thinner construction that is better suited for low-profile implementations and tighter or dynamic bends.

The mating durability of the connector is an important factor to consider. If cables are repeatedly disconnected and reconnected, the connectors must be rated for multiple operating cycles to avoid costly and inconvenient replacement. Connectors are also at risk of damage when installers have no visual access to the mating pair and must instead rely on blind mating. To combat this, connectors that prevent incorrect mating should be specified; polarization, shrouding, and keying mechanisms help achieve this. Generous leading edges can be included in the design of both the male and female elements of the mating pair, which help correctly align the connectors. The shrouding on these connectors ensures they remain securely aligned in the mated position. It is important to ascertain which features are needed to tackle mis-mating. In some situations, a degree of angled misalignment can be accommodated by the connector pair at the start of mating.

The locking mechanism selected is very important, as it needs to be secure enough to prevent connectors and cables from being unintentionally detached. At the same time, it must be quick and simple for an installer to efficiently make all the necessary cabling connections.

The Archer Kontrol industrial connector series from Harwin is suitable for blind-mating applications. Available in configurations with 12-80 contacts fitted, these 1.27 mm pitch connectors achieve impressive performance parameters. Each contact can carry currents of 1.2 A and data rates up to 3 Gb/s are supported. The shrouded design (with built-in polarization) safeguards every contact.

Finding an optimal solution

There are many factors to consider when sourcing connectors and cabling for industrial usage. It is vital to understand the electrical, mechanical, and environmental performance characteristics that are needed to address the numerous challenges posed by uncompromising industrial environments. Specifying application-specific connectors and cabling for industrial applications can be a complex process but matching a connector to the unique conditions in which it will perform ensures long and reliable performance.

Visit Harwin online to learn more about connectivity solutions for industrial settings.

Like this article? Check out our other Harsh Environment and Ruggedized articles, our Industrial Market Page articles, and 2022 and 2021 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- How to Source Connectors and Cabling for Industrial Applications - February 8, 2022

- Nine Considerations for Building a High-Reliability Cable Assembly - February 16, 2021