Rolling with the Changes: 2013 Product/Technology Trends

2013 Product/Technology Trends

The trends that have driven the electronics industry for the past five years continued to evolve in 2013. Many of the new connectors introduced during the year reflect the density and performance demands of applications that consume less space, operate at higher speeds, weigh less in mobile products, and may contribute to the thermal management strategy of the device. Rather than introduce entirely new connector families, many suppliers chose to upgrade the performance of existing products. Bandwidth creep was apparent in many product announcements during the year.

The trends that have driven the electronics industry for the past five years continued to evolve in 2013. Many of the new connectors introduced during the year reflect the density and performance demands of applications that consume less space, operate at higher speeds, weigh less in mobile products, and may contribute to the thermal management strategy of the device. Rather than introduce entirely new connector families, many suppliers chose to upgrade the performance of existing products. Bandwidth creep was apparent in many product announcements during the year.

The relationship between copper and optical links is a good example of the factors that are shaping the future of connectors. In terms of data rates, the bar is constantly being pushed higher as designers continue to find ways to extend the perceived limits of copper. Existing high-speed copper I/O and backplane interconnects are being upgraded in order to support next-generation applications. Universal Serial Bus connectors, for example, have evolved from the original 12Mb/s to the current SuperSpeed USB 3.0 operating at 5Gb/s.

Pluggable I/O connectors such as QSFP began life running four channels at 10Gb/s, and have progressed through QSFP+ to the most current zQSFP+ connectors that provide an upgrade path to 28Gb/s per channel. SFP and QSFP interfaces have grown in popularity due to a combination of greater bandwidth, increased port density, and the flexibility of copper or fiber media.

Pluggable I/O connectors such as QSFP began life running four channels at 10Gb/s, and have progressed through QSFP+ to the most current zQSFP+ connectors that provide an upgrade path to 28Gb/s per channel. SFP and QSFP interfaces have grown in popularity due to a combination of greater bandwidth, increased port density, and the flexibility of copper or fiber media.

Standards-writing organizations and SIGs such as PCI are recognizing the need for optical alternatives and have responded with their OCulink specification that defines both copper and fiber implementations in PCIe applications. This specification will define an internal and external interface operating up to four lanes at 8Gb/s per lane at lengths not practical with copper.

The cost of optical alternatives to copper interconnects continues to fall. For at least the past 10 years, engineers have predicted that the combination of crosstalk, skew, reflections, susceptibility to EMI, and signal attenuation of copper links would mandate the transition to fiber. Many systems today operate at 8-10Gb/s with the next plateau targeting 15 to 25Gb/s. As data rates push past 10Gb/s, the practical maximum length of a copper channel becomes progressively shorter unless advanced signal conditioning devices are utilized. The Apple Thunderbolt interface is an example of a high-speed link that has been enabled through the use of active signal conditioning devices integrated into the cable assembly.

Fiber optic links suffer from none of these signal integrity issues with the added advantage of nearly unlimited bandwidth. The limiting factors for fiber have historically been device cost, energy consumption, and heat generated by the electro-optic conversion process. The reluctance of the industry to adapt to an unfamiliar media has also been a factor in adopting this technology. A combination of physics and economics are beginning to change this equation. We have seen tremendous interest in active optical cables that feature standard electrical interfaces. The electro-optical conversion occurs in the cable connector backshell, which allows the transmission of high-speed signals over fiber to the opposite end where the optic signals are converted back to electrical pulses. Active optical cables require no change to the equipment I/O panel while enabling much longer runs with greater signal fidelity.

Fiber optic links suffer from none of these signal integrity issues with the added advantage of nearly unlimited bandwidth. The limiting factors for fiber have historically been device cost, energy consumption, and heat generated by the electro-optic conversion process. The reluctance of the industry to adapt to an unfamiliar media has also been a factor in adopting this technology. A combination of physics and economics are beginning to change this equation. We have seen tremendous interest in active optical cables that feature standard electrical interfaces. The electro-optical conversion occurs in the cable connector backshell, which allows the transmission of high-speed signals over fiber to the opposite end where the optic signals are converted back to electrical pulses. Active optical cables require no change to the equipment I/O panel while enabling much longer runs with greater signal fidelity.

Samtec introduced a PCIe X8 active optical cable assembly that is capable of supporting PCIe Gen 1; Gen 2 at up to 300 meters; and Gen 3 up to 100 meters.

Optical cables are also becoming practical in shorter applications and are now being considered for applications inside the rack and even within the box. Suppliers such as Samtec, US Conec, and Avago have introduced miniature optical engines that launch multi-gigabit optical signals directly off the board via flat ribbon assemblies for chip-to-chip, chip-to-board, or board-to-board applications.

Research in the science of silicon photonics will result in the ability to fabricate optical and electronic devices on a common silicon die using conventional manufacturing processes. Direct optical links between processors will bypass the distortion and loss associated with signals propagated via even the best printed circuit board materials.

The bandwidth, crosstalk, and channel length limitations of copper are also forcing designers to consider alternatives to traditional backplane design. Orthogonal midplanes can greatly reduce the channel length in large backplane systems.

In an effort to further reduce signal distortion introduced by the midplane, Molex and other suppliers are developing direct orthogonal midplane concepts where daughtercards mate orthogonally, eliminating the midplane entirely.

In an effort to further reduce signal distortion introduced by the midplane, Molex and other suppliers are developing direct orthogonal midplane concepts where daughtercards mate orthogonally, eliminating the midplane entirely.

Another approach is to replace traces on a backplane with discrete or ribbon twinaxial cables. These point-to-point cables offer much lower distortion and attenuation than the highest performance laminate but introduce a new set of mechanical, manufacturing, and maintenance issues.

Another approach is to replace traces on a backplane with discrete or ribbon twinaxial cables. These point-to-point cables offer much lower distortion and attenuation than the highest performance laminate but introduce a new set of mechanical, manufacturing, and maintenance issues.

With 10Gb Ethernet now being widely implemented and the specifications for 40 and 100Gb Ethernet waiting in the wings, the industry is moving toward the development of practical alternatives to copper. Few designers today anticipate copper cables of any length at future 400Gb, and eventually 1Tb Ethernet speeds.

Power and managing its resultant heat remains the focus of many design engineers. Power connectors are playing a key role in addressing both issues. Connectors used in high-current applications continue to sport increased power ratings through the utilization of higher-conductivity materials and optimized contact geometries. Molex rates its EXTreme PowerMass board-to-board connector at 150A per blade. Connector profiles are being reduced to minimize obstruction of cooling airflow and may include open housings that allow air to circulate around the contacts to keep them cooler. Many power connectors are offered with the ability to mix high and medium power contacts along with signal contacts in a single housing, often in highly custom configurations.

Power and managing its resultant heat remains the focus of many design engineers. Power connectors are playing a key role in addressing both issues. Connectors used in high-current applications continue to sport increased power ratings through the utilization of higher-conductivity materials and optimized contact geometries. Molex rates its EXTreme PowerMass board-to-board connector at 150A per blade. Connector profiles are being reduced to minimize obstruction of cooling airflow and may include open housings that allow air to circulate around the contacts to keep them cooler. Many power connectors are offered with the ability to mix high and medium power contacts along with signal contacts in a single housing, often in highly custom configurations.

At the other end of the spectrum, mobile battery-operated products, such as tablet computers and smartphones, place incredibly challenging demands in terms of packing density and weight. Continued functional integration has reduced the number of internal interconnects to a few FEC connectors linking devices mounted on small PCBs or flex circuits.

The markets that utilize connectors are undergoing rapid transformation. The rate of change over the past five years has been astounding.

Just ask the folks at Blockbuster about how people have changed their method of accessing movies. In the three years since the introduction of Apple’s iPad in 2010, this entirely new class of device has grown to 184 million units in 2013, with annual growth rates of tablet sales near 50%.

Low-power-consuming devices using ARM architecture have revolutionized the electronics industry, making tablets and smartphones the preferred devices for communications and accessing the Internet. In some cases, entire classes of electronic devices are being obsoleted by applications that enable a single device to be multifunctional. Consumers have discovered newer smartphones can produce better photos then a point-and-shoot or even SLR camera. GPS-based applications guide users to their destinations and assist in finding the best price at a local store. Desktop computer sales have dropped off sharply and laptop computers are not hitting their forecast sales volumes.

Tablet computers achieve incredible packaging density to achieve as small a profile as possible. The result has left little room for I/O interconnects. Micro USB, a 3.5mm headphone jack, or a proprietary Apple Lightning connector populate the minimal I/O panel space left on these devices. Wireless technologies, including Wi-Fi and Bluetooth, as well as proposed optical I/O, will continue to impact traditional I/O interfaces. Internal as well as external connectors that feature exceptionally fine pitch will continue to represent major growth segments. Traditional stamped and formed metallic contact technology may be approaching practical limits, which will drive research for alternatives that offer higher signal integrity and panel density.

Incredible advances in robotics and 3D printers are opening entirely new opportunities for electronic connectors. A typical car now contains multiple computers that manage everything from passenger comfort and safety to emissions. Medical monitoring, diagnostic, and even therapeutic devices are moving from the hospital to community clinics, doctor offices, and to the home. Some of these devices will become near-consumer items, which will require I/O connectors that can survive use by untrained patients, as well as be aesthetically attractive.

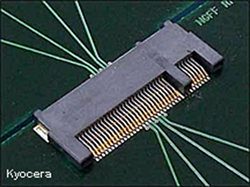

Several new connectors introduced this year reflect changing technology, such as memory. Suppliers like FCI Electronics and others have tooled DDR4 DIMM sockets as this new generation of memory modules enters the market. Recognizing the growing adoption of solid-state disk drives, TE Connectivity and Kyocera launched new lines of M.2 next-generation form factor connectors that consume the minimal space available in ultrabooks and tablet PCs.

Several new connectors introduced this year reflect changing technology, such as memory. Suppliers like FCI Electronics and others have tooled DDR4 DIMM sockets as this new generation of memory modules enters the market. Recognizing the growing adoption of solid-state disk drives, TE Connectivity and Kyocera launched new lines of M.2 next-generation form factor connectors that consume the minimal space available in ultrabooks and tablet PCs.

Applications in military, intelligence, and avionics are growing rapidly. The advent of unmanned aerial, land, and underwater vehicles, along with the Future Soldier program, is generating new classes of military-grade equipment that requires absolute reliability in rugged conditions. Connectors will need to be smaller, lighter, offer higher bandwidth/power rating, and be cost-effective to support reduced government budgets.

On the commercial side, Internet traffic continues to grow at a record pace. More users demanding greater bandwidth continue to drive server farm expansion. Introduction of “micro servers” greatly increases system capacity per rack and may result in reduced demand for cables between servers, but higher performance aggregating cables to switches and routers.

In many market segments, software has become the key enabler to advanced services. Hardware reliability is critical, but software improves accessibility, ease of use, as well as improved user-friendly interfaces, such as voice, gesture, and touch.

The electronic connector industry will continue to be challenged to stay ahead of the rapidly shifting demands of the markets they serve. 2014 is shaping up to be another year of challenges and opportunities for those willing to innovate and evolve.

- Optics Outpace Copper at OFC 2024 - April 16, 2024

- Digital Lighting Enhances your Theatrical Experience - March 5, 2024

- DesignCon 2024 in Review - February 13, 2024