Not Old, Just Older: Legacy Connectors in Current Designs

| By Raymond Yuen, Portfolio Director – Commercial at FCI ElectronicsLegacy connectors are dependable, reliable devices that offer design engineers a no-risk solution that has been proven in the field for decades. These interconnect products typically offer the most cost-effective solution, as these commodity devices are standardized and do not involve customized engineering or specialty designs to meet application requirements. The majority of legacy products also have multiple sources to support customers, providing better margins for OEMs. Legacy connectors are important in the industry, as suppliers that deliver legacy devices have sound high-volume manufacturing experience and know-how. As a result, design engineers trust the quality and in-field performance of legacy interconnect products and continue to use them in mature and new designs.

Because it was born out of DuPont, Berg Electronics, and other connector manufacturers since acquired, for example, FCI has accumulated a vast legacy product portfolio, including D-subs, modular jacks, terminal blocks, and their associated I/O cable assemblies; standard 0.8 mm to 2.54 mm pitch board-to-board and wire-to-board products; memory connectors like SO DIMM and DDR; and many others that are still undergoing design improvements and finding new applications to support. In the connector industry, D-subs are a well-established product series developed in the early 1950s. When D-subs were first introduced, they were among the smallest connectors used in computer systems. Most OEMs have continued to use these reliable, low-cost legacy connectors in their designs. Some OEMS even treat D-sub connectors as a de facto standard for their equipment’s I/O connections. D-subs have evolved over the years to include additional standardized features and modifications. For example, waterproof D-subs for adverse environments, high-density and micro D-subs for smaller-size equipment, and combination D-subs that deliver power and signal, provide options for OEMs to continue using these mature products in new computer, telecom, datacom, and gaming applications. The modular jack connector was developed by Berg Electronics, working with Western Electronic AT&T (FCI acquired Berg in 1999). The first applications were to provide modular connectivity between wireline phone handsets, phone bases, and the wall outlets for those phones. The great majority of early products used wire leads to connect the other points in the devices. Although the internal applications for wireline phones faded away over the years, the modular jack (RJ45, in particular) is now widely used in networking applications. Applications include wireless modems, telephones, PCs, and servers for switch connections in datacenters. A 2 mm pitch board-to-board connector (Minitek) was first developed for hard disk drive (HDD) I/O applications. Its small size was the main selling point, as it fit the drive form factors of the time. Although Minitek has been replaced by SATA and SAS connectors in those applications, it has evolved to become a modular system that is used as a general-purpose interconnect in many end products. The Minitek Series has since been expanded to include a wire-to-board solution suitable for industrial and instrumentation equipment and other general purpose applications, as well as a smaller 1.27 mm pitch version for OEM customers that require a more dense solution utilizing a proven platform. Furthermore, as HDD application demands for increased speed within a smaller footprint continue, connector manufacturers have expanded SATA and SAS connectors beyond the 3 Gb/s range to include 6 Gb/s and 12 Gb/s products. Unshrouded headers for pin-in-paste (PIP) processes (BergStik) were designed for IBM computers in the 1950s. The evolution of the personal computer and the set-top box has driven demand for this connector. Pin-in-Paste (PIP) technology allows the use of TMT products in SMT manufacturing processes. The connectors are automatically or manually placed on the board, then soldered in the same operation as the SMT components. Despite this, the mechanical strength of the TMT soldering is maintained, which is still an important requirement for connectors nowadays in many mil/aero, industrial, and automotive applications. The first BergStik connectors were straight 0.025 square wire products molded into plastic. As computer technology advanced, so too did the BergStik, decreasing in size but increasing in functionality. This board-to-board solution was one of the first interconnects to be used as a mezzanine connector, enabling multiple board stacking. Today, an extensive range of thru-hole and surface-mount products is available, including single- or double-row headers in either straight or right-angle orientation. A 1.0mm board-to-board connector system (Conan) was developed in the early 1990s for use in Motorola pagers. The same connector was also adopted in a number of other mobile applications, such as mezzanine mobile PCs, board-to-board connections in early mobile phones, and bar code scanners. Many of those applications faded away as lower-cost, one-piece connection options, such as FFC/FPC connectors, became available, but this fine-pitch, robust, board-to-board connector has found a home in POS (point-of-sale) machines and smart meters. Legacy products are continuously being enhanced to meet new market and application demands. One example is a low-profile, high-density, parallel board-to-board connector system that was one of the first mezzanine connectors to utilize the unique blade-on-beam design. Developed more than 20 years ago, the BergStak connector features a 0.8mm double-row contact pitch that conserves printed circuit board space to meet telecommunication, datacom, and industrial applications. Since its inception, the mezzanine connector system design has been optimized to meet PCI Gen 3 qualifications and support high-speed performance of up 10 Gb/s with reliable signal integrity. The connector system delivers increased connection integrity with early receptacle contacts points, precision-tapered contacts for mating stress control, and polarization capabilities to ensure precise contact positioning for accurate mating alignment and reliability. In addition, the connector system family has been expanded to include a wide range of sizes and stack heights, from 40- to 200- position sizes in 20-position increments; and 5mm to 16mm stack heights in 1mm increments. Customization options are also available to meet virtually any application requirement. Despite the rapid development of new, innovative interconnect technologies throughout the years, legacy connectors still have a place in today’s modern electronics manufacturing world. These proven devices, both in terms of in-field performance and volume manufacturing, are still vital in many of the original applications they were designed for, as well as in today’s high-tech equipment. The tested and validated intermating capability of legacy devices with compatible connector products provides customers with the security and competitive price benefits of dual sourcing. Legacy products are still undergoing design improvements to serve new applications in expanding markets that engineers in the 1950s only dreamed about. |

Product Gallery

FCI’s reflow compatible, pin-in-paste Delta D-sub connector series features thru-hole technology to help customers reduce their total applied cost.

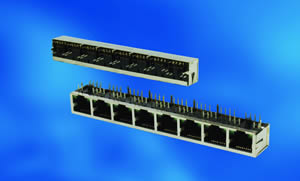

The low profile RJ45 1-stack, 8-port shielded connector with LED is designed for Gigabit Passive Optical Network (GPON) systems and offers a more bandwidth-efficient protocol for data-centric services.

The Minitek™ 2.0mm-pitch modular connector system, with a 0.1 coplanarity for all surface mount parts, consumes significantly less space on the PCB versus similar connector devices.

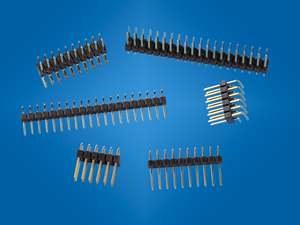

The economical BergStik® un-shrouded headers feature industry-standard 0.64 mm square post contacts on 2.54 mm pitch. The extensive range of through-hole, surface mount and pin-in-paste part options include single- or double-row headers in either straight or right angle orientation.

The Conan® 1.0mm-pitch, low-profile, board-stacking connector system is designed to provide a mechanically secure, high-density electrical interface between parallel printed circuit boards.

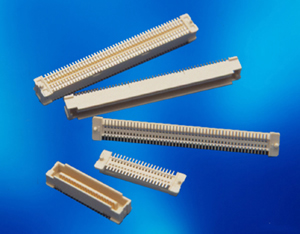

The BergStak® mezzanine connector system features 0.8mm double-row contact pitch to minimize board space while delivering high-speed performance of up 10 Gb/s along with reliable signal integrity performance. |

Delta D-sub connectors

Delta D-sub connectors RJ45 1X8 Modular Jack connector

RJ45 1X8 Modular Jack connector Minitek™

Minitek™ BergStik®

BergStik® Conan®

Conan® BergStak®

BergStak®