Smaller Medical Devices Create Space for Micro Connectors

As personal medical devices follow the path of consumer electronics, product miniaturization has made it easy for patients to integrate these technologies into their lives. Medical machines for hospital settings are also scaling down and becoming available to more facilities. Micro and miniaturized interconnects play a key role in enabling these medical equipment trends.

The medical device market is focused on products that are small and light while still delivering high power, high speed, and robustness. Personal medical devices are following the path of consumer electronics, making them easy for patients to use and integrate into their everyday lives. Medical machines for hospital settings are also decreasing in size to lower the cost and make them more available to smaller facilities. Miniature and micro connector solutions are at the heart of this downsizing trend.

“On the industrial side, it’s about making big things smaller, more portable, and more efficient to use,” said Michael White, technical marketing specialist at Hirose Electric. The consumer side is heavily influenced by, among other things, an increase in telemedicine. For that market, he said, “the desire is to make equipment and technology wireless and portable.”

White explained that from a product perspective, four categories in addition to miniaturization come into play to address these trends: high power, high speed, and efficiency (power, EMI, secure mating). Junya Doi, consumer electronics specialist at Hirose, added that the trend involves a combination of power and board space. The need for passing a certain amount of amperage with the smallest possible footprint is becoming more evident.”

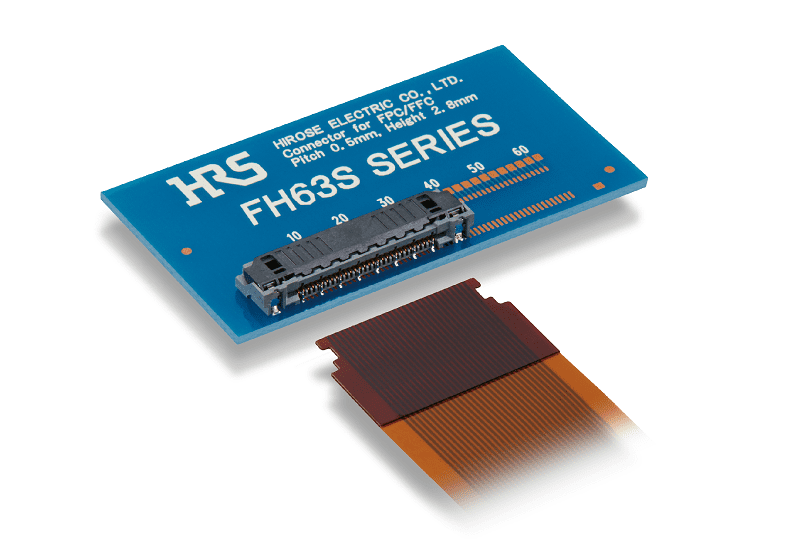

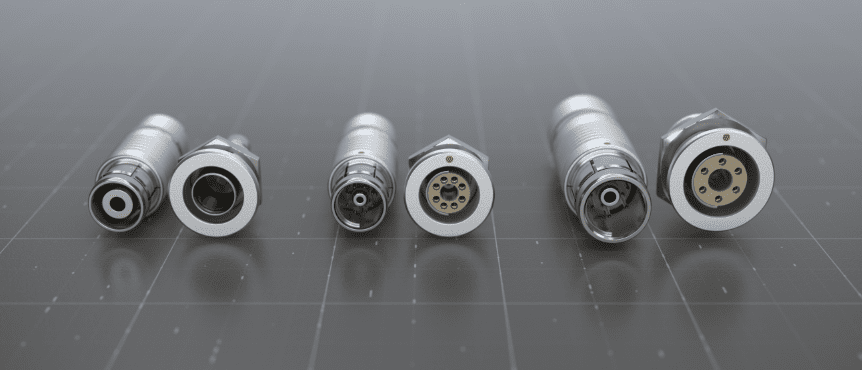

Hirose’s LF Connector, available from Mouser Electronics, a circular I/O connector with shielding, is available with waterproof construction and in mini sizes for medical, industrial, and other harsh environment applications.

High speed and shielding for power and data are more of an issue for industrial equipment than for consumer medical devices such as wearables, said White. For high speed, Hirose offers the LF Connector, a circular I/O connector with shielding that is also capable of running Cat6A standard and compliance.

Efficiency is impacted by the ease and security of mating connectors. In medical devices, the security of the connections is critical. Producing equipment for medical imaging, testing, or diagnostics takes years of development and approvals. “Efficiency also means avoiding product malfunctions and product defects. That extends to the manufacturability,” said Scott Ginnett, director of marketing at Hirose. “There’s nothing more damaging to a company than producing products that suddenly have problems. You don’t want it to come down to a small connector that didn’t properly mate with the flex connector. Efficiency in terms of avoiding product malfunction and defects starts by getting more efficiency in the connection.”

Hirose’s One Action FH technology enables connectors to be mated without lifting the actuator.

Incorporating feedback into the connector design, particularly in I/O connectors, is a way to build in efficiency and ensure the connection is secure. “Whether it’s visual or something that you feel in your hand or something you hear, that feedback provides the confirmation that you’ve indeed mated that connector successfully,” said White. “It’s always important, but perhaps especially in medical applications, to avoid mis-mating and incomplete mating. A connector design that is intuitive to the user thrives in this space.”

OEM’s are developing smaller, more cost-effective versions of costly full-size machines that integrate smaller connectors. “Manufacturers can make a smaller one that will be less expensive,” said David Ptacek, national sales director for Fischer Connectors. “We can make a smaller connector by making it a little more compact. We can make it hermaphroditic (male and female pins in the same side) and compressing the side, with a larger back end of the contact where the wire goes in that can accept the larger gauge wire.”

Hybrid configurations of two or three types of channels integrated within one single, small, multi-tasking cable/connector help medical OEMs make devices smaller, lighter, and easier to use. The versatile Fischer Core Series in brass offers fluidic connectors (above) in different sizes and hybrid configurations used in various pneumatic instruments with compressed air supply for puncturing, drilling, sawing, shockwave, etc., in surgery, dentistry and therapeutic systems. They are sterilizable up to 500 autoclave cycles, withstand up to 10,000 mating cycles, resist high shock and vibration, and their robust key mechanism ensures safe and secure connections.

This is especially important for county and rural hospitals that provide access to care for people who don’t live near a large medical facility. “A lot of the major manufacturers are trying to right-size a robot for that environment, instead of having everybody drive a couple hundred miles or so for a procedure,” said Ptacek. Increased demand for smaller equipment is also evident in orthopedic surgery, which requires a great deal of physicality. Machines that are easier to handle give a greater number of surgeons the ability to work in this field, regardless of their size, he added. “They want devices that will have smaller and lighter cables and connections, that push more power, and have more capabilities, such as RF and 4K. That means the space is going to get smaller and compact.”

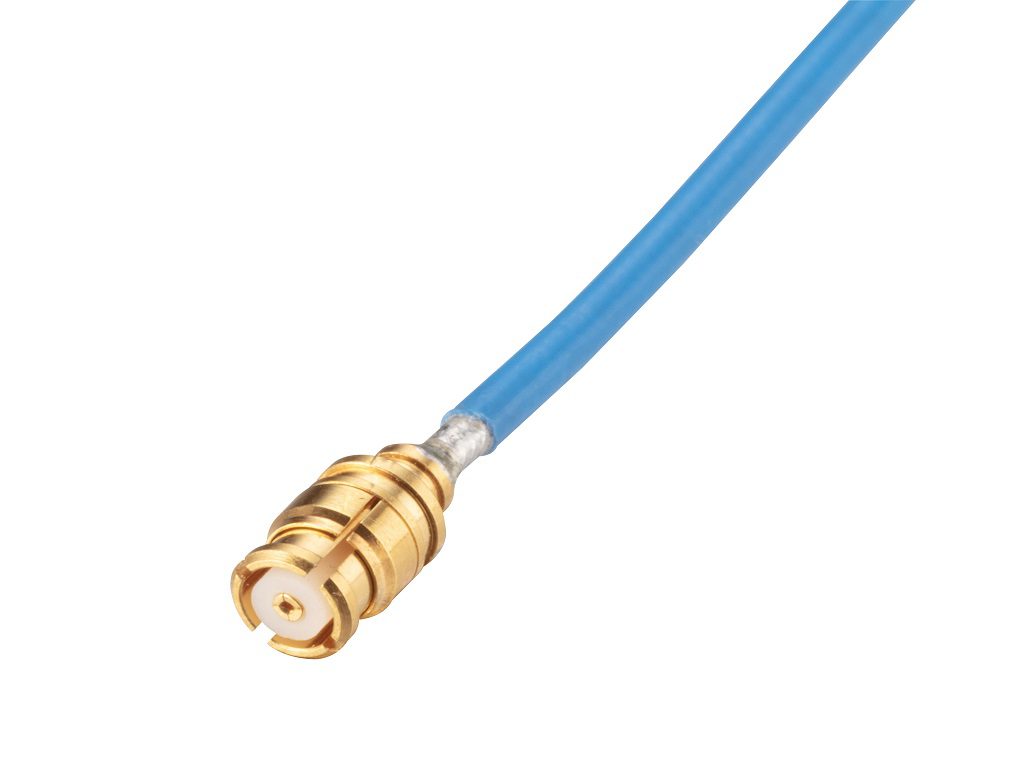

TF-047 from Times Microwave is ideal for medical applications like flexible catheters, medical imaging, and patient monitoring applications. Micro-coaxial cables enable next-generation devices to deliver advanced treatment or high-resolution imaging.

“Applications such as precision medical devices present unique equipment challenges, demanding specialized interconnect solutions that must be high-performance, safe, and reliable,” said Kai Loh, product solution manager at Times Microwave Systems. “Micro coaxial cables are enablers for next-generation medical devices that deliver advanced treatment or high-resolution imaging. They are a key building block for highly integrated medical cable assemblies with improved maneuverability and safety. The XtendedFlex 045 is a game-changer, with a unique construction and customizability to address increasing needs for compactness and flexibility, low attenuation, and thermal dissipation. And the new TF-047 adds another dimension to our lineup of micro-coaxial cables.”

Micro connectors improve home care

Medical devices for home use differ from the technology found in clinical environments. They are becoming more like other consumer electronics. Making these devices easy to use, less obtrusive, and more comfortable to handle increases the chances of patients using them and using them correctly. Sascha Gres, business development manager at Harwin, explained that equipment for use at home must be easy to use for untrained people, as well as lightweight, compact, and easy to carry. Any issues with reliability could potentially affect monitoring accuracy or treatment effectiveness.

Blood pressure monitors for people with hypertension are typically portable units that run on batteries. Someone with diabetes may use a blood glucose monitor, taking periodic measurements every day. “These checks can be done with a wearable or a handheld sensor. People with arrhythmias can have their heart rate continuously monitored via a wearable ECG device. The acquired data can then be transmitted (across an internet connection) to the relevant specialist for subsequent in-depth analysis,” Gres added.

Harwin’s Archer .5 and Archer .8 connectors are used in space-limited medical designs, such as insulin pumps.

Insulin patch pumps and tubeless insulin patch pumps are small digital devices that are an alternative to insulin injections. The devices can be programmed to automatically deliver doses of insulin on a regular schedule, day and night. This automatic system helps patients maintain their blood sugar levels within their target range. To work properly, it must be attached to the patient’s body most or all of the time. Some devices are part of a closed loop system, reducing or eliminating the need for human interaction, explained Sobin Hiraoka, business development manager, Molex Consumer & Commercial. A closed loop system has a sensor (CGM) that measures the glucose level, communicates this information to the insulin pump (often accompanied by a coordinating mobile app), and delivers the appropriate amount of insulin, all within a connected system. (In a typical, non-closed loop system, the CGM does not communicate with the insulin pump for automated insulin delivery.)

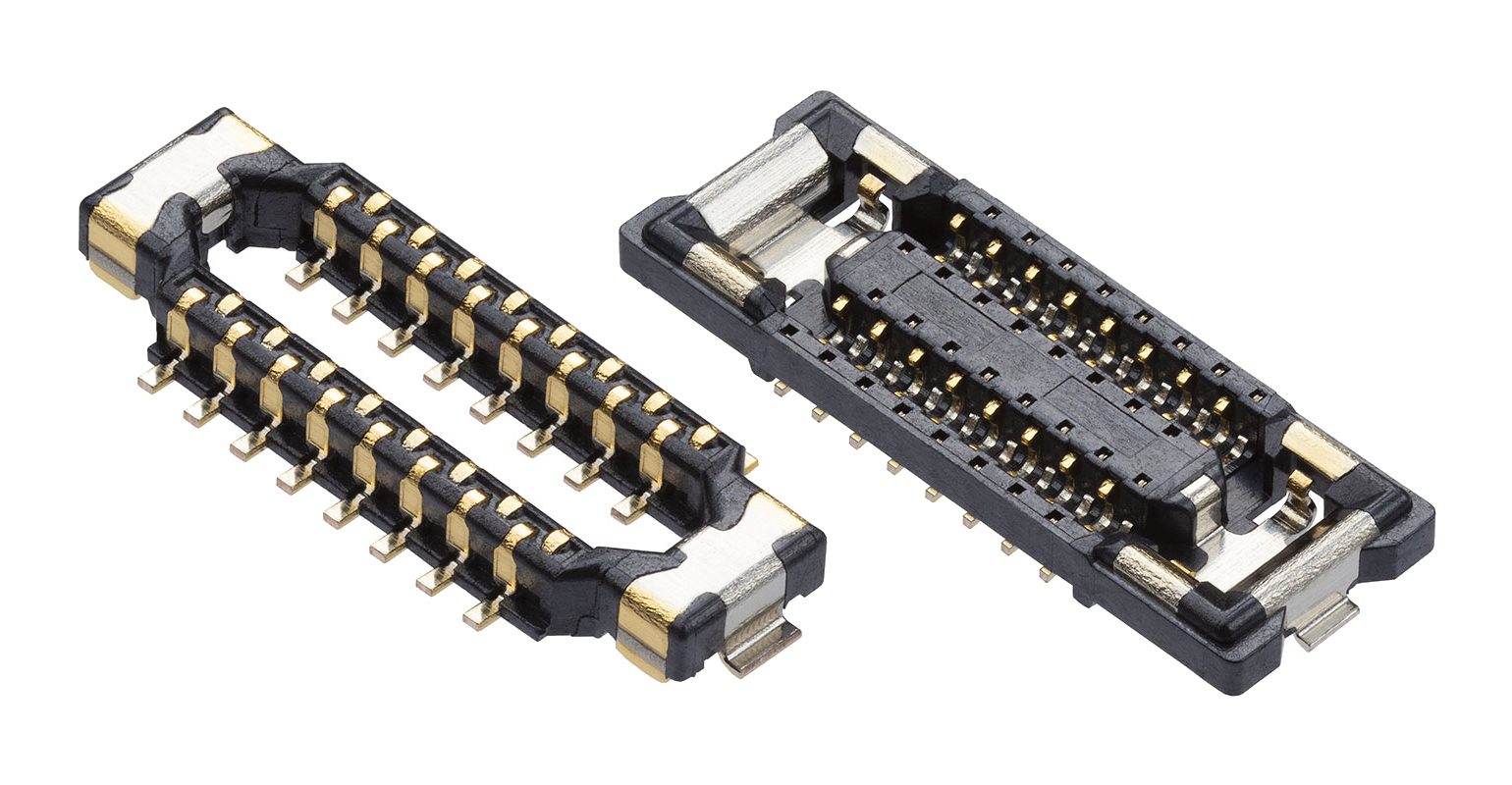

Quad Row, part of Molex’s Core Products, is the industry’s highest density board-to-board connector available. This two-row system enables a 30-40% shorter length when compared to standard two-row connectors, due to its 0.175 mm signal pitch (while the soldering pitch remains at an industry standard 0.35 mm pitch).

“The drive for smaller, more reliable and optimal wireless connectivity for patch pumps and supporting wearable hardware requires connector miniaturization and a wide variety of antenna options,” said Hiraoka. “Connector miniaturization includes decreasing and staggering the signal pitch to minimize the PCB footprint, as well as shrinking the connector to a height less than 1.0 mm. A great side benefit to this is lighter weight connectors.”

Hiraoka explained that several connector features improve the device’s reliability. Metal power nails and inner covers, along with insert molding, increases the connector robustness. Terminal and nail locks provide additional retention force to prevent connector disconnection. Many of Molex’s type C connectors offer IPX7 and IPX8 waterproof protection, helping to protect sensitive PCBA components from liquid and dust intrusion.

Wireless connectivity and implementation can be a tricky endeavor, whether it’s maximizing efficiency or determining a suitable location for the antenna. Oftentimes, consultation with an RF engineer will be required to help customers with such challenges. In addition, a wide variety of sizes and types of internal and external antennas, covering wireless protocols such as Bluetooth low energy (BLE), WIFI, NFC and LTE/5G, will aid design engineers in finding an ideal solution.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for Hirose Electric, Fischer Connectors, Times Microwave, Harwin, Molex, and Mouser Electronics. See also: Mouser’s overview of new medical wearable technologies.

Like this article? Check out our other High-Reliability and Wearable articles, our Medical Market Page, and our 2023 and 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Mezzanine Connectors Product Roundup - April 16, 2024

- Out Now! New eBook Shares Bright Ideas for Electrification - April 16, 2024

- What are ARINC 801 Connectors? - April 9, 2024