M12 and M8 Connectors: The Perfect Choice for Industry’s Harsh Environments

M12s and M8s deliver even in the most disruptive conditions. These workhorse connectors are available with extensive options that serve many different industrial environments.

Challenging Conditions

Today, electronic connections and communications are needed in harsh environments at sea, in space, and in various conditions on Earth. These activities include manufacturing, robotics, agriculture, food and beverage processing, military, transportation, ocean exploration, mining, and pipelines for water and fuels. To be successful in harsh conditions, connectors must prevent the ingress of water, dust, and sand. They must also withstand extreme temperatures, vibration, and pressure conditions while providing reliable signal transfer. All of these capabilities must exist within a confined space and require minimal servicing. M12 and M8 circular connectors are available in a wide range of variants and with myriad accessories. This popular connector type is a great choice for harsh- and remote-environment applications with high data-transmission needs.

Engineered for maximum flexibility, ERNI’s modular M8 and M12 circular connectors are available with various coding options and accessories, including protective caps and O-ring seals, and are suitable for almost all fieldbus specifications.

Data Transmission

M12 D-coded connections have long provided reliable signals for home, office, and factory needs. As automation becomes more connected and Industry 4.0 continues to transform industrial operations, demands are growing for Industrial Ethernet. D-coded M12 products, which are capable of up to 100Mb/s Ethernet, are now being replaced with X-coded M12 products capable of up to 1Gb/s Ethernet transmission rates to keep up with data demands. In a manufacturing environment, X-coded M12 connectors are better suited to handling factory noise, factory process needs, and harsher environments, and are even able to respond better to data processing on the plant floor. Beyond manufacturing, X-coded M12 connectors can be called upon for use in applications such as IP cameras, public transportation, railway infrastructure, and broadcasting systems.

Remote Locations

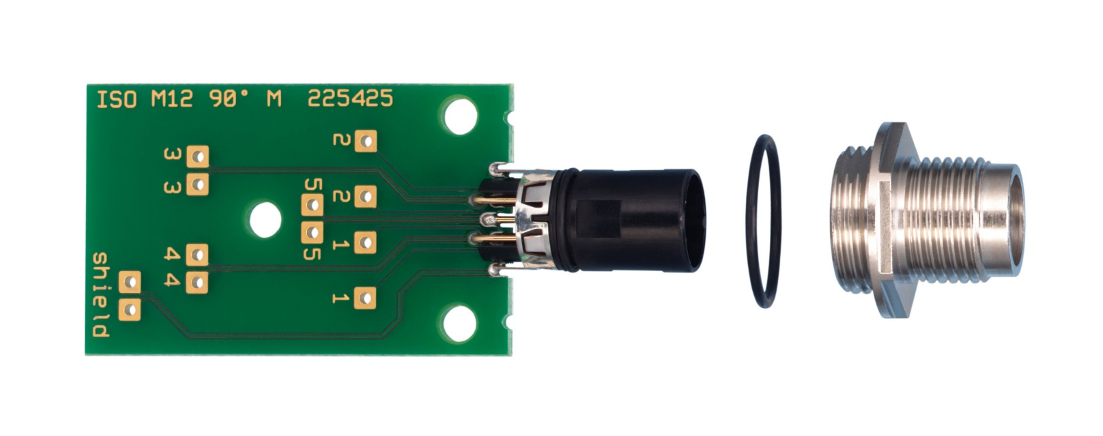

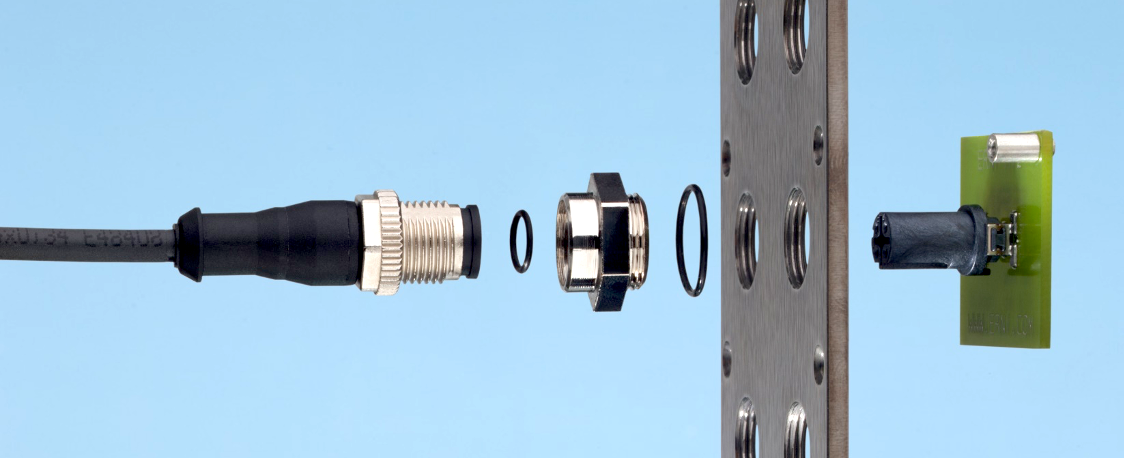

Industrial activities extend beyond the manufacturing floor to the exploration of planet Earth. Much of this type of exploration calls for sensors that can monitor varying temperature, pressure, moisture, and vibration conditions. Angled M12 connectors with a Comparative Tracking Index (CTI) of 600 are insulated against these harsh-environment applications. An engineer could also choose to add shields and O-rings to achieve an IP65/67 M12 connector solution when connectors are mated and locked to reliably deliver signal in harsh, remote conditions.

ERNI offers a variety of M12 right-angle connectors.

Dust and Debris

Connectors used for heavy equipment and agricultural applications must be designed to prevent the ingress of water, dust, sand, and chemicals, as well as perform in extreme temperature, vibration, and pressure conditions. Rugged construction and materials are critical to ensuring reliable signal transfer in harsh environment conditions, and well-designed connectivity products can fit in tight spaces and require minimal servicing, making them easy for operators to use.

M12 and M8 connectors are available with IP ratings that range from IP67 (i.e., total protection from dust and up to 30 minutes of water protection at depths of up to one meter) to IP69K (i.e., products proven to reliably withstand sanitary washdown conditions) and an extensive combination of pin counts, shields, terminations, and codings to the meet the grueling demands of mining, agriculture, earth moving, and other harsh-environment applications with expanding data demands. These solutions will keep dust, sand, water, and other hazards out while providing quality signals to onboard or remote operators.

M12 connectors equipped with O-rings can provide rugged protection from debris and water in harsh-environment applications with increasing data demands.

Since their market introduction in the mid-1980s, M12 connectors have continued to evolve in terms of features and functionality to meet the changing demands of industry’s many harsh environments. Increasing connectivity across all segments of industry demands high reliability and strong signal integrity from smaller footprints. As we continue to increase efficiencies across industries, M12s will continue to be the connector of choice. These workhorses offer the extensive options and rugged designs required to deliver in disruptive conditions. They are easy to install and modify, making M12 and M8 connectors an effective solution for harsh-environment signal applications.

For more information, visit ERNI online.

Like this article? Check out our other Connector Basics, ruggedized and M12 articles, our Industrial, Mil/Aero and Transportation Market Pages, and our 2021 and 2020 Article Archives.

- M12 and M8 Connectors: The Perfect Choice for Industry’s Harsh Environments - May 4, 2021

- M12 and M8 Connectors: The Perfect Choice for Harsh Environments - September 15, 2020

- Connectors for IoT, IIoT, and Industry 4.0 Applications - February 18, 2020