Harsh Environments No Longer Derail Reliability of Railroad Crossings

New connector technologies help make rail crossings safer, easier to maintain, and more resistant to weather and other environmental challenges.

From Boston to Los Angeles and all around the world, drivers experience the frustration of waiting at a railroad crossing for a train to pass. While watching the passing rail cars, many of us look down the tracks to see how much longer it will be. Most people don’t realize how much technology is involved in the systems that alert us that the train is approaching and we shouldn’t cross those tracks. The flashing lights and the ringing bell of the railroad crossing, likely equipped with a safety gate, work continuously through the years, through the full range of weather and harsh environment challenges, reliably relieving motorists of the risk of determining when it is safe to cross. These crossings are truly a marvel of modern technology.

We have certainly come a long way from the days when gatekeepers sitting in a small shanty manually raised and lowered crossing gates. Today, most swinging round signals, or “wigwags,” have given way to two alternating flashing red lights controlled by connected technologies.

For over 80 years, junction boxes equipped with standard AAR posts, lugs, nuts, washers and “gold nuts” controlled most rail crossings.

Rail Crossing Junction Boxes

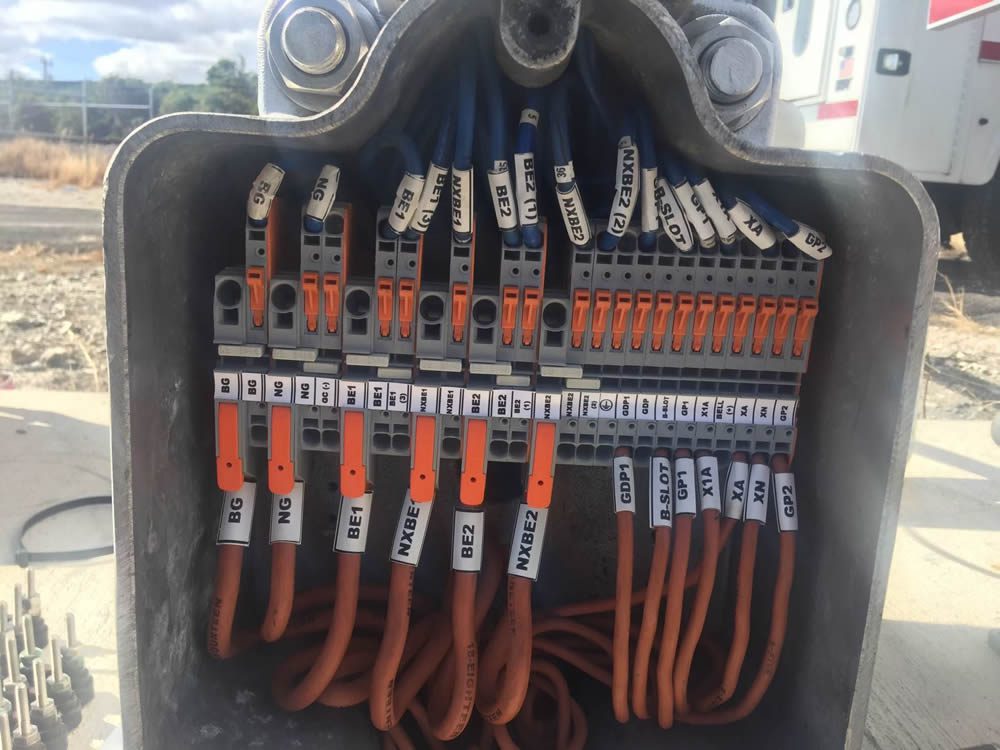

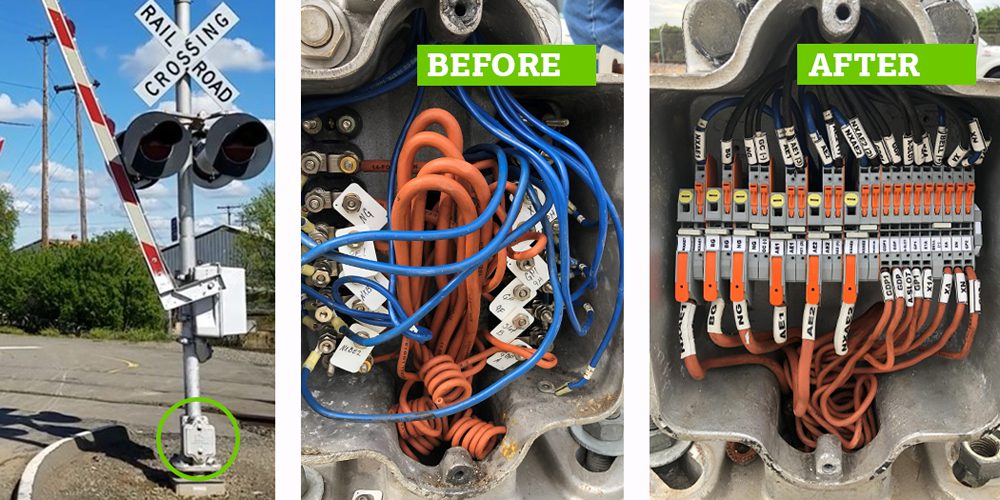

The connections in crossing junction boxes, located at the base of the mast, are a complex series of electronics that ensure the lights flash and the gates raise and lower at the correct time. For over 80 years, these junction boxes have been equipped with standard Association of American Railroads (AAR) posts, ring lugs, nuts, washers, as well as gold nuts used to disconnect the power for testing and maintenance. These connections must be made by a highly skilled person using calibrated crimp tools. Their job is even more difficult when factoring in the weather conditions and working at ground level next to a grade crossing. These terminations take hours to complete and test.

Over time, the components inside of crossing junction boxes may corrode and become loose due to constant shocks and vibrations. Even one loose wire can cause train stoppages and delays. Accessing these connections for repair is time-consuming and expensive. Railway industry design engineers decided it was time to move away from the decades-old AAR terminations as well as fuse blocks and test switches that were bulky, took a lot of time to wire, and were not touch-safe. They needed a way to create more reliable, rugged, high reliability, and maintenance-free connections.

Innovative alternatives reduce installation time, improve safety and reliability, make testing easier, and reduce costs. For example, WAGO’s TOPJOB S DIN Rail Mount Terminal Blocks make installation faster and reduce the time that technicians are in vehicle traffic areas. With direct wire insertion, all they need to do is strip the wire and insert it without having to use ring lugs or crimping tools. The CAGE CLAMP design ensures a reliable, maintenance-free, touch-safe connection without the trouble of torquing the connections. Additionally, WAGO’s intuitive, orange knife-disconnect terminal blocks permit technicians to easily disconnect/reconnect individual circuits for testing without lifting wires. This orange disconnect replaces the gold nuts used in the old design. The new design is made complete with markers, jumpers, and end clamps, giving the junction box a cleaner design that is easy to assemble and maintain.

WAGO’s TOPJOB S DIN Rail-Mount Terminal Blocks provide a safe wiring option for applications that must endure harsh environment conditions.

A significant concern for the railway industry is long-term durability. Evaluating how these new connectors will perform under suboptimal conditions is essential to building trust in new technology. Weather and other extreme conditions, such as shock and vibration, need to be addressed to ensure a reliable, long-lasting connection. One harsh environment test is the 500-hour salt spray test. This IEC 68-2-11 compliance test makes sure that these connections can stand up against corrosion and exposure to wet conditions such as rain and snow.

Perhaps the most important test is IEC 61373, which tests components for ruggedness under railway-specific shocks and vibrations. To meet this standard, connector suppliers must demonstrate that products can “withstand tests of reasonable duration that simulate the service conditions seen throughout its expected life.”

Wiring in railroad crossing junction boxes is cleaner, safe, and easy to access with WAGO TOPJOB S DIN Rail Mount Terminal Blocks.

These tests, along with many others conducted over the course of several hundred hours, ensure that WAGO products are designed and built to withstand the rigors of a harsh environment. Innovative interconnect solutions help advance not only the railway industry but also other harsh environment markets that benefit from fast, reliable, cost-effective, and maintenance-free connections.

Visit WAGO – Railway Systems to learn more about rugged solutions for the transportation industry.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Harsh Environments No Longer Derail Reliability of Railroad Crossings - October 11, 2022

- Wire Connections Then and Now - March 31, 2020