Industrial Rectangular Connectors Evolve to Meet New Application Needs

Industrial rectangular connectors have been a mainstay of heavy-duty and automation applications since the 1950s. Tomorrow’s rectangular automation connectors will look much the same as they do today — on the outside. But inside, these connectors are becoming more powerful, capable, and versatile.

The foundational need for proven durability ensures that tomorrow’s industrial rectangular connectors will look much the same as they do today. But the range of internal options that define the connector platform’s versatility will expand to include next-gen connectivity features like RF, communications, fiber optic modules, switches, and more. These features will be introduced alongside the signal, power, fluidic, and pneumatic connections so popular today.

A key advantage of modular rectangular connectors is their backwards and forwards compatibility. The pace of innovation in the automation arena has already started to accelerate, but Industry 4.0 will take decades to fully implement. And many of the changes will be achieved through ongoing small and affordable steps that involve upgrading rather than replacing existing equipment.

As Industry 4.0 and the Industrial Internet of Things (IIoT) influence factory design, transformative technologies such as inductive power transport robots and point-to-point gigabit frequency RF systems will become part of manufacturing processes. These facilities rely on iterations of the Han-type rectangular connectors first introduced by HARTING in the 1950s. The Han connector is the mother of all ruggedized industrial rectangular I/Os. It was originally designed to provide a rugged, high-performance connector that could be used in application areas across markets. This connector type replaced hardwiring with fast, easy connectivity, and with more than six decades of growth it is a mainstay of machinery, plants, wind turbines, rail applications, and shipboard equipment. Numerous connector suppliers offer a version of the rugged rectangular industrial connector. Why has it remained so successful? Because it has continued to evolve.

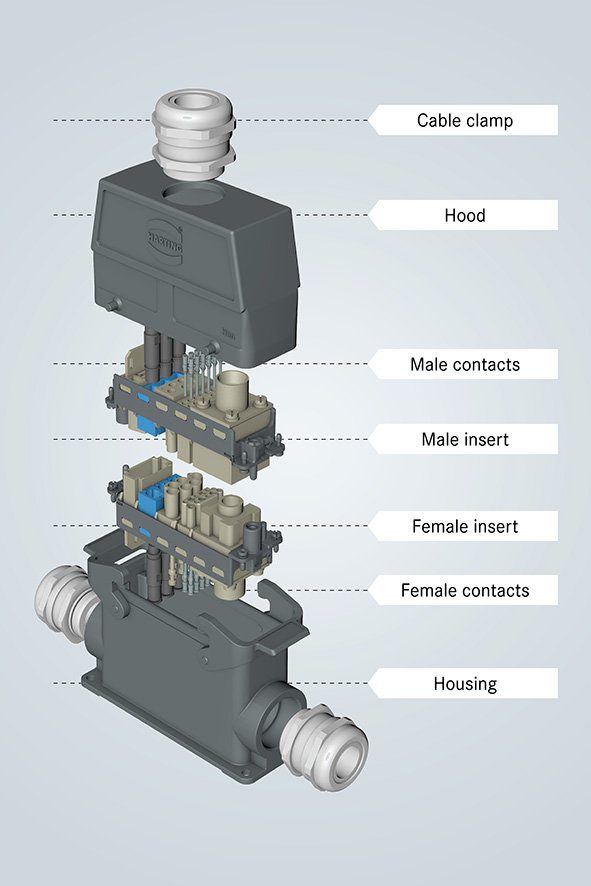

HARTING’s Han-Modular connector, an update of the original 1950s design, was introduced in 1993 and merges power, signals, data, fluid, and compressed air into in a single ruggedized shell.

To serve the complex needs of future industrial environments, HARTING redesigned its rugged rectangular connector to offer more versatility in a smaller shell. The Han-Modular Domino system, introduced in July 2022, allows for greater miniaturization and digitalization. This updated connector shrinks the lowest common denominator element in the Han connector from a full width to a half-width module that can carry anything from higher pin count interfaces to circular X-coded M12 connectors and high-speed Ethernet connectors. As importantly, it allows for dummy placeholder modules that will enable engineers to increase the density of their legacy signal interconnects as well as retain space for next-gen modules. It doubles the number of modules that can fit into the standard rectangular shells. The backwards compatibility of the Domino system makes it easier for companies to upgrade their equipment, said Gada Inokaityta, HARTING product manager.

The Han-Modular Domino modules system offers more connectivity options in a smaller shell size.

The step up to half-width modules that can work alongside full-width modules should be a small one for those connector companies that include global companies like Molex, TE Connectivity, and Amphenol Sine; Italian company ILME (available from Newark), Turkish company Mete-Enerji, and Germany’s Lapp Group, entrenched companies that started as geographic niche players; control cabinet wiring system leaders like Phoenix Contact and Weidmüller, who pioneered many screw- and spring-lock termination options to optimize the field wiring of enclosures and DIN rail systems as well as insert options for modular rectangular connectors.

Amphenol Sine’s heavy|mate heavy-duty connector series, available from Mouser Electronics and Newark, is a modular connector line consisting of hoods, housings, inserts, and contacts used to create a customizable solution for harsh environments.

The VARIOCON connector system from Phoenix Contact allows individual connections for transmitting currents up to 70 A and voltages up to 1000 V for devices, junction boxes, and control cabinets. Housing options, modular contact inserts, and contact carriers for crimp contacts enable flexible connections for signals, data, and power.

Weidmüller’s RockStar ModuPlug integrates more functions while requiring less weight and space in its modular connector system.

Lapp Group’s EPIC connector, available from Allied Electronics & Automation, is a safe and removable connection suitable for industrial applications in machine building, control cabinets, and in outdoor applications

The HARTING Domino modules are in the introduction phase and engineering samples are just now becoming available. None of the connector companies mentioned above have introduced compatible modules, but it may not be long before they do, as the presence of half-width modules should make it easier for any of them to add new modules into their housings.

As the amperage goes down, the same signal size isn’t needed, so the module can come down to signal connector or leaf connector in a smaller shell, with room for fiber, RF, or other functions. Plus, their collective exposure to all variety of market leaders almost ensures that the significant innovations from all corners of the electronics world will get designed into the Han connector platform in one way or another.

The basic industrial rectangular connector has continued to evolve and thrive for four main reasons:

Simplicity. The modular rectangular connector assembly has more than 100 unique component options, with thousands of potential interface variations. You don’t need to retool everything just to introduce a new higher-speed industrial Ethernet link.

Cost. The next industrial revolution will accelerate upgrades as systems become more complex. Building upon a configurable system is more affordable than all-new wiring and components.

Field-proven and trusted. Rugged rectangular shells and contacts have been tested in the worst conditions and under decades of harsh cleaning protocols. The amperage ratings of the shells are confirmed for all variety of power configurations and temperature environments.

Blanket channel support. Companies like HARTING have direct relationships with the large automation OEMs but the niche industries and contractors are often served (and better served) by the legions of sales reps, distributors, and value-added integrators who also offer complementary products and services.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for Allied Electronics & Automation, HARTING, Molex, Mouser Electronics, Phoenix Contact, TE Connectivity, Weidmüller, and Würth Electronik.

Like this article? Check out our other articles on Automation and Transportation, ourIndustrial Market Page, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Cell Towers Become Less Cluttered - January 10, 2023

- Market for Smaller LC Duplex Fiber Connectors Makes Big Gains - November 1, 2022

- Twinax Cable is Replacing PCBs Inside Server and Switch Applications - October 4, 2022