Twinax Cable is Replacing PCBs Inside Server and Switch Applications

To reduce heat and improve speeds, twinax cable assemblies are replacing PCBs in next-generation datacom equipment.

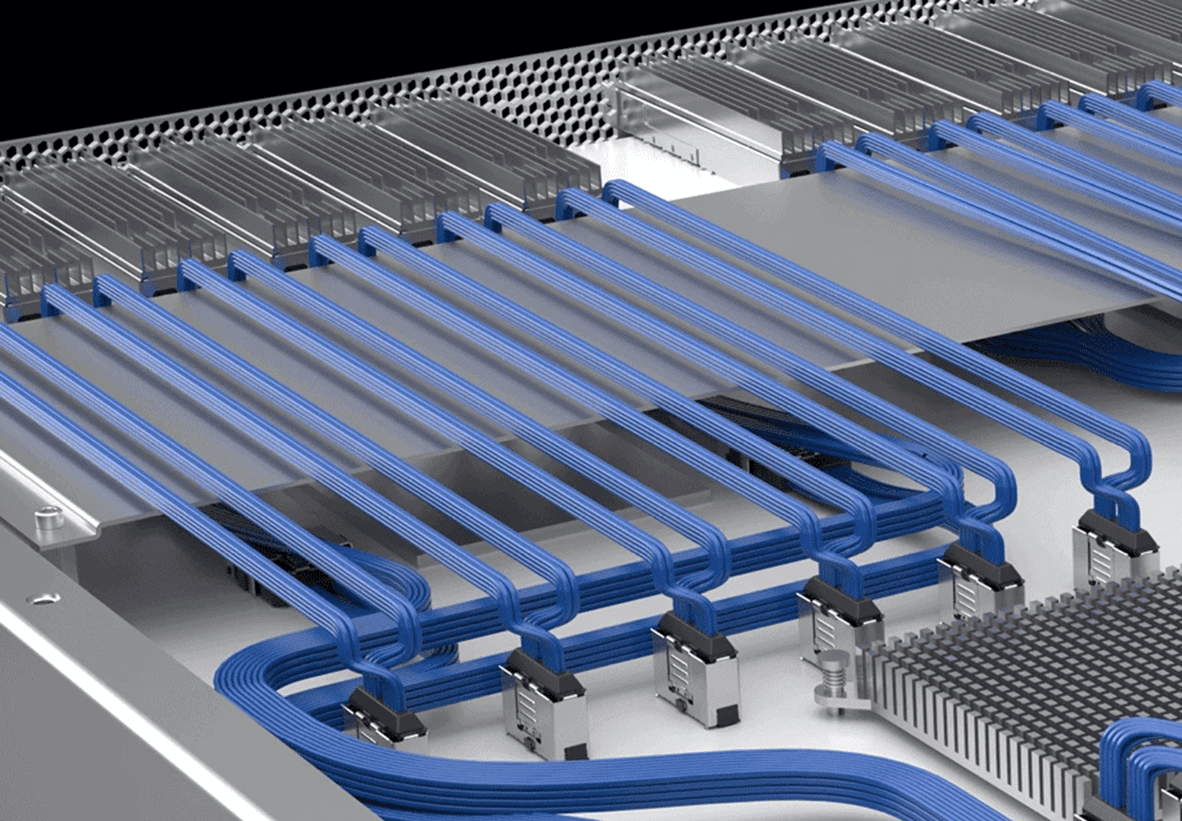

The links inside a switch that connect the quad small form factor pluggables (QSFPs) at the faceplate to application-specific integrated circuits (ASICs) at the heart of the box have become signal superhighways. The capacity and the number of I/O ports per switch is rising. So is the capacity of both the transceivers at the I/O panel and the ASICs at the heart of the system.

With increased signal speed comes heat and the simplest way to eliminate heat is to reduce resistance. System engineers have turned to twinax cable to eliminate the heat that can collect in “lossy” multi-layer PCBs.

The transition from PCBs to twinax began taking shape years ago and was driven by the development of electrically characterized twinax cable assemblies that could outperform the best-in-class PCBs (widely considered the Panasonic Megatron 6).

Besides eliminating the heat that can accumulate in multi-layer PCBs, twinax cable offers a number of advantages, including:

- Simplified port synchronization: No need to route around vias.

- Reduced front-end costs: Twinax solutions enabled a reduction in the number of PCB layers needed and also eliminated the need for retimer chips.

- Improved modularity: Moving the signals to a separate media made it easier to tier product offerings with different port counts and price points.

The twinax solutions for these applications are electrically characterized as assemblies with the complete assembly defining their performance.

Major players and their electrically characterized twinax solutions:

| Cable Assembly Overview | Twinax Cable | |

| Amphenol | QSFP OverPass™ | SkewClear EXD |

| Molex | BiPass | TwinMax |

| I-PEX | Leapwire | N/A |

| Samtec | Flyover® | Eye Speed® |

While the connector interface on the panel/transceiver side of the harness is well-defined in the latest QSFP-DD specifications, the connector interfaces on the ASIC side at the heart of the system are non-standard and continue to evolve.

Samtec jumped out as an early leader in the category and would argue the technical superiority of its cable. Samtec offered early adopters a range of solutions for the interface nearest the ASIC.

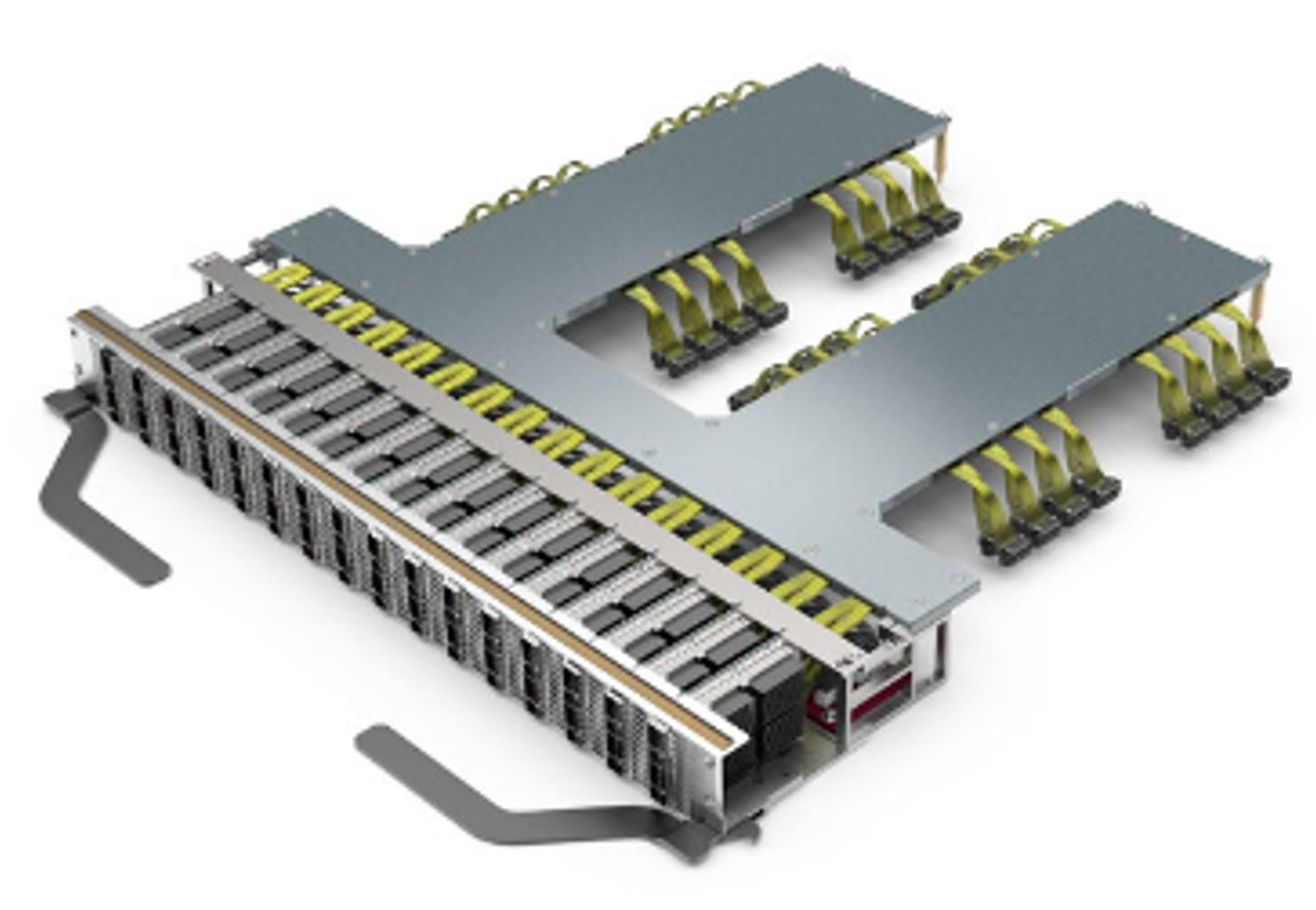

Molex, which enjoys a very strong position on the QSFP-DD committee and has been very strong in the area of cabled backplane connectors, offers a variety of customer-centric solutions. Among these is a configurable tray approach which allows white box manufacturers a way to characterize iterations of the system as a whole.

Molex offers a wide range of integrated product solutions for high-speed cable assemblies, including configurable trays.

Amphenol and I-PEX entered the fray with low-profile solutions for the cable-to-ASIC interface which address more recent trends in the ways electronic components are being co-packaged with the ASIC assembly on a single substrate.

Amphenol recently introduced its Densi-link overpass assemblies that allow for cables from multiple QSFP ports to be ganged together near the ASIC chip.

I-PEX’s Leapwire connector (left) and Amphenol’s Densi-link connector (right).

The technical evolution for this interface is far from over. I-PEX, a relative latecomer to the party, offers a very low-profile, high-performance solution that can be positioned under the ASIC heat sink. In early 2022, Panasonic introduced the Megatron 8, which offers dramatically better performance than the Megatron 6, long considered the best-performing PCB product. But chances are slim that the industry will turn back to PCB material for this interface.

The industry is driving hard to develop and standardize an optical cable bridge that extends all the way to the ASIC. Development of industry standard co-packaged optical links and chip sets seems inevitable. However, the need for strong electrical alternatives for this interface will remain. A high percentage of the intra-rack or short-line connections are all-electrical and use direct-attach cable assemblies like those from Molex.

The move to replace PCB material with twinax cable is not isolated to the QSFP (transceiver) to ASIC board link in the communication intensive parts of a data center. It is also happening in the data processing intensive zones at the core of hyper-scaled cloud computing server farms.

To improve modularity and design flexibility, the backplanes that were used to interconnect the multiple PCBs in a traditional rack are being replaced by high-performance cables and smaller format modules connectors (that still are referred to as backplane connectors because of their high pin counts and electrical performance).

Most likely, fiber-optic links will continue to reach deeper into the data center. The highest-end data processing systems have for many years used complex fiber-optic “backplanes” pre-configured into a plastic sheet to provide easy reconfiguring of shelf-to-shelf connections. It is easy to imagine how a concept like the Molex tray system could be repurposed on a smaller scale for an intra-box fiber-optic FlexPlane system. Time will tell how this whole trend plays out, but each advancement takes us a step closer towards faster, more powerful, more efficient system design.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for Amphenol Communications Solutions, I-PEX, Molex and Samtec Inc..

Like this article? Check out our other articles on Cable, Cable Assemblies, our Wire and Cable Assemblies Market Page, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Cell Towers Become Less Cluttered - January 10, 2023

- Market for Smaller LC Duplex Fiber Connectors Makes Big Gains - November 1, 2022

- Twinax Cable is Replacing PCBs Inside Server and Switch Applications - October 4, 2022