Formula E’s Gen 3 Car Embraces the E-mobility Racing Mission

Connector companies play a big role in advancing the technology behind electric powertrains and battery management systems. The Formula E race series showcases the progress in the high-performance vehicle market.

The ABB FIA Formula E World Championship electric car racing series is a proving ground for electric mobility, advancing the technology for everyday use as well as for the broader goal of sustainability in cities around the world. In December, the series’ Gen3 car made its debut in Valencia, Spain, to kick off the 2023 racing season. According to Formula E, the Gen3 era represents a huge technological leap, bringing race teams and fans “the fastest, lightest, most powerful and efficient electric single-seater ever — and the most sustainable too.”

The Gen3 reaches a top speed of 200 mph (320 kph). With a smaller chassis, it is 60 kg lighter, yet has an additional front powertrain with an increased power output of 100 kW compared to Gen2. More than 40% of the energy used in-race comes from regeneration under braking — nearly double the capacity of Gen2. All this points to a thrilling year of racing. Interconnect suppliers, including TE Connectivity, ept connectors, and Southwire, along with distributors like Mouser Electronics (DS PENSKE Racing), have played an important role by sponsoring vehicles and developing technologies for the vehicles.

Formula E’s 2023 Gen 3 race car. (Gen3 images courtesy of FIAFormulaE.com)

Paul Webb, TE Connectivity’s long-time global product manager for the DEUTSCH Autosport range of connectors, has seen firsthand the developments and the excitement generated by the Formula E teams. Webb explained that the competition is a battle of powertrain, rather than aerodynamic, efficiency. The chassis is made by Spark Racing Technology in France. The teams each have the same aerodynamic kit and battery, to which they add their own powertrain. “The races come down to who can optimize the amount of electricity used up during the race series,” said Webb.

The cars look identical from a distance. The differences are under the engine cover where the inverter motors from various manufacturers are found. “This creates quite close racing, because it’s then down to the person behind the wheel and how they press the pedals and turn the wheel and use their energy as efficiently as possible. As a driver, you can manage the race in different ways. You can go off like a bullet and try and make some distance or you can hold back and then hopefully have enough energy at the end,” Webb said. He added that the drivers must also be prepared for the unpredictability inherent in all auto racing. “You can’t forecast when someone’s going to put the car in the wall and there’ll be a yellow flag and everyone’s all bunched up again. You sort of guess and hope that you get it right.”

Efficiency through weight optimization

In addition to the powertrain design and functionality, minimizing weight is a big part of maximizing the car’s energy efficiency. Every vehicle has a minimum weight, and that includes safety features and the survival cell, the central part of the car where the driver is seated. How the components are placed around the car and optimized directly affects the vehicle’s performance. “You want the weight to be as low down and as centralized as possible, so that your roll motion when you go through a corner isn’t negatively impacted by something being high up and causing extra sort of wobble for the driver,” said Webb.

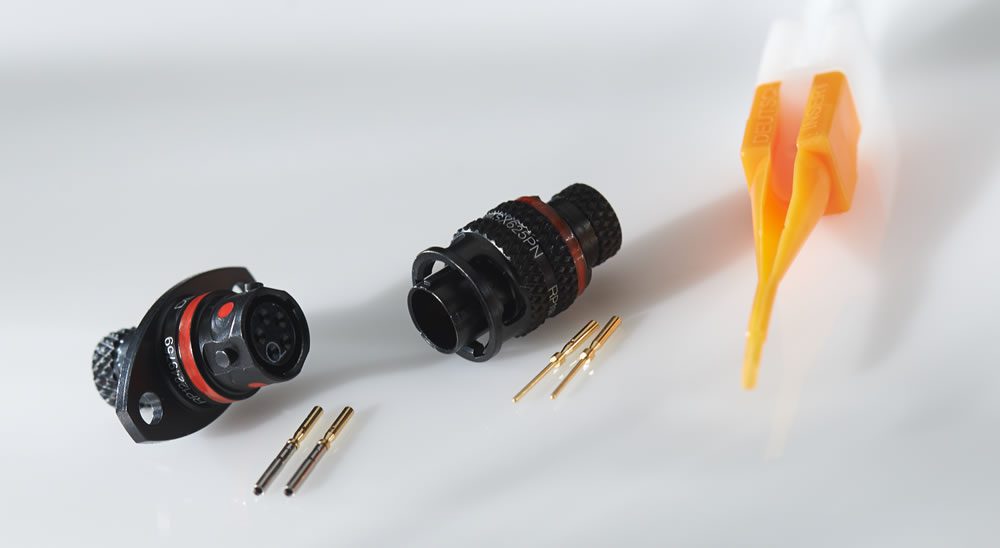

With their ultra-compact design, the DEUTSCH AS MICRO XTRALITE series connectors from TE offer racing teams the smallest, lightest package for three, five, and six wires. 6-way is the shortest, lightest AS connector for six wires, offering a solution where space is most restrictive.

Connectivity improves performance

In Formula E, the powertrain consists of a battery, called a RES (rechargeable energy store), that contains wired cells that measure temperature and general performance. Maintaining an optimized temperature is a critical part of performance. Any electric vehicle has less range in the winter than in the summer, and similarly, if the battery is too hot, it won’t perform correctly, Webb explained. Also included is a big charging connector that is engineered with many safety features, and a number of DEUTSCH Autosport connectors. These connectors transmit the performance and safety elements of the battery and optimize the way the battery cells are balanced. The power travels from the battery into the inverter, and then into the electric motor. “In the early days, these were two separate items, but in the Gen3 car, they’ve been combined by most teams, into a single unit, with no extra wires, which optimizes the packaging and the performance,” said Webb. This eliminates potential points of failure and areas where heat can dissipate by current transferring back and forth. Fewer wires also mean less weight.

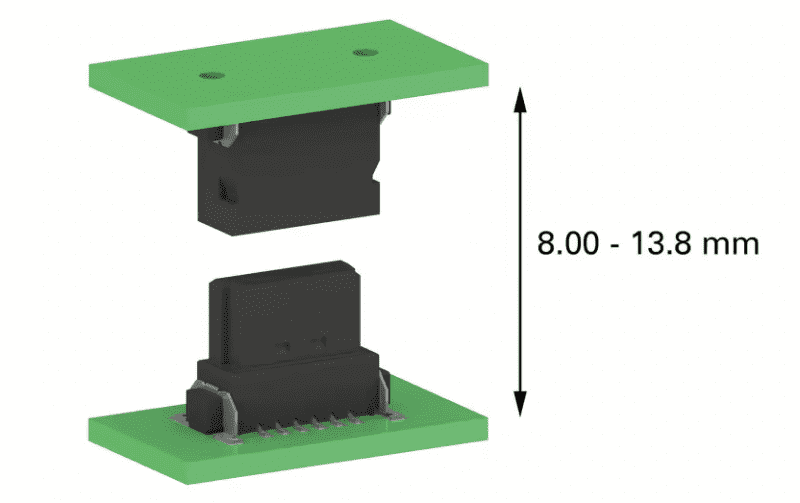

One27 1.27 mm SMT from ept USA is used in the most essential sections of an EV: electric motor/battery management systems and inverters (or powertrain). The benefit of One27 in a Formula E vehicle comes down to fast communication and overall quick reaction time to power a high-demand inverter. The 10+ GB/s and amps per pin of up to 6 amps provide the powerful combo for the communications board of the BMS for the inverters. One27 uses available space as efficiently as possible and saves room for additional functions, while still supplying power extremely reliably.

Connectors gather and transmit essential race data

Webb explained that Formula E cars, just like other race cars, have an ECU that measures what’s going on in the vehicle. Some of that data is transmitted to Formula E, some goes back to the teams, and some (including video) is used for TV transmissions. The data comes off the car via an electrical harness that’s distributed throughout the car with wires going out to all the extremities and to where the driver sits. It monitors the driver pressing the pedals or turning the steering wheel, and how much force is being used to do that. It measures factors that are safety critical and performance critical, such as wheel speed, brake wear, brake temperature, and tire pressure.

Teams can also measure ride height and how the car goes over bumps. “You don’t want it hitting the deck because that decreases your lap time. But equally you don’t want it up too high because that gives the car too much roll movement and yaw through corners,” said Webb. “The other thing they’re measuring is the energy consumption. The idea is to finish the race with the battery essentially dead, which means you’ve optimized it throughout the race. Drivers can’t just go off the line and drive like a maniac for the entire race distance; the battery won’t last that long.”

To be successful in Formula E, Webb shared that the drivers, mainly ex-Indy Car and ex-Formula One drivers, must adapt their racing style to fit the idiosyncrasies of electric vehicles. “They lift and coast into corners instead of firing into the corner and diving on the brakes at the last minute, chucking the car in and then jumping back on the power. In Formula E, the best way round is to find a point on the lap where you come off the power early, let the car slow down through a bit of friction and aerodynamic load, then get on the brakes and lose as minimum speed as possible, tip it into the apex of the corner, and as soon as you feel the front of the car starting to grip, just eke the power on again. This optimizes the way the energy is being deployed.”

Connectors for all conditions

Because the Formula E races are held all over the world in a variety of environmental conditions, the connectivity solutions must be adaptable to heat, cold, and vibration. Heat is generated by the car itself, not just the outside temperature. That has led the teams to adjust the battery placement and design systems to reduce the amount of heat generated. One way this is accomplished is by combining the inverter and motor to eliminate heat-generating wired connections. Formula E cars’ energy regeneration is a two-way flow of energy that also creates heat. “As you go into a corner, instead of the electric motor taking power it sends power back into the battery. Managing that was a big problem. Initially, people were using larger cables and larger contacts than they needed because they didn’t know how it was going to work,” Webb said.

The 2023 Formula E racing series began in Mexico City on January 14, and travels to Saudi Arabia, India, South Africa, South America, Europe, Indonesia, and the United States, ending in London in late July. Visit Formula E for the complete calendar.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for ept connectors, Mouser Electronics, and TE Connectivity.

- Testing is Vital for Electronics Performance and Reliability - May 7, 2024

- Connectors for Test & Measurement Product Roundup - May 7, 2024

- May 2024 New Connectivity Products - May 7, 2024