What are solderless terminals?

What are solderless terminals?

Meet the Connector: Solderless Terminals

Solderless terminals provide a simplified wire joining solution. Whereas soldering provides a permanent connection, solderless terminals are advantageous in applications where connections may need to be disconnected for repair or if a change in design or components is imminent.

TE Connectivity pioneered crimping technology and termination products in the 1940s, transforming the complex process of soldering wire connections into one that is simpler, more reliable, and more cost-effective. Many electronics and industrial customers across various markets use solderless terminals. Compared to soldering, solderless connections are less expensive, easier, and less labor-intensive to install.

Solderless terminals can be used on both wire and cable connections. Several types are available, including ring, spade, hook, flange, slotted tongue, as well as parallel, closed end, and butt splices, ferrules, bullets, and quick disconnects. Each of these comes in a variety of styles.

The termination is often made using a crimp tool designed for the specific size and style of the terminal. The quality of the crimper is as important as the quality of the terminal. The terminal may be open barrel (also called stamped terminals or pins) or closed barrel (a cylindrical metal barrel with no gap). Each type requires a specific crimp tool. Manufacturers will often recommend the crimper to use with the terminal.

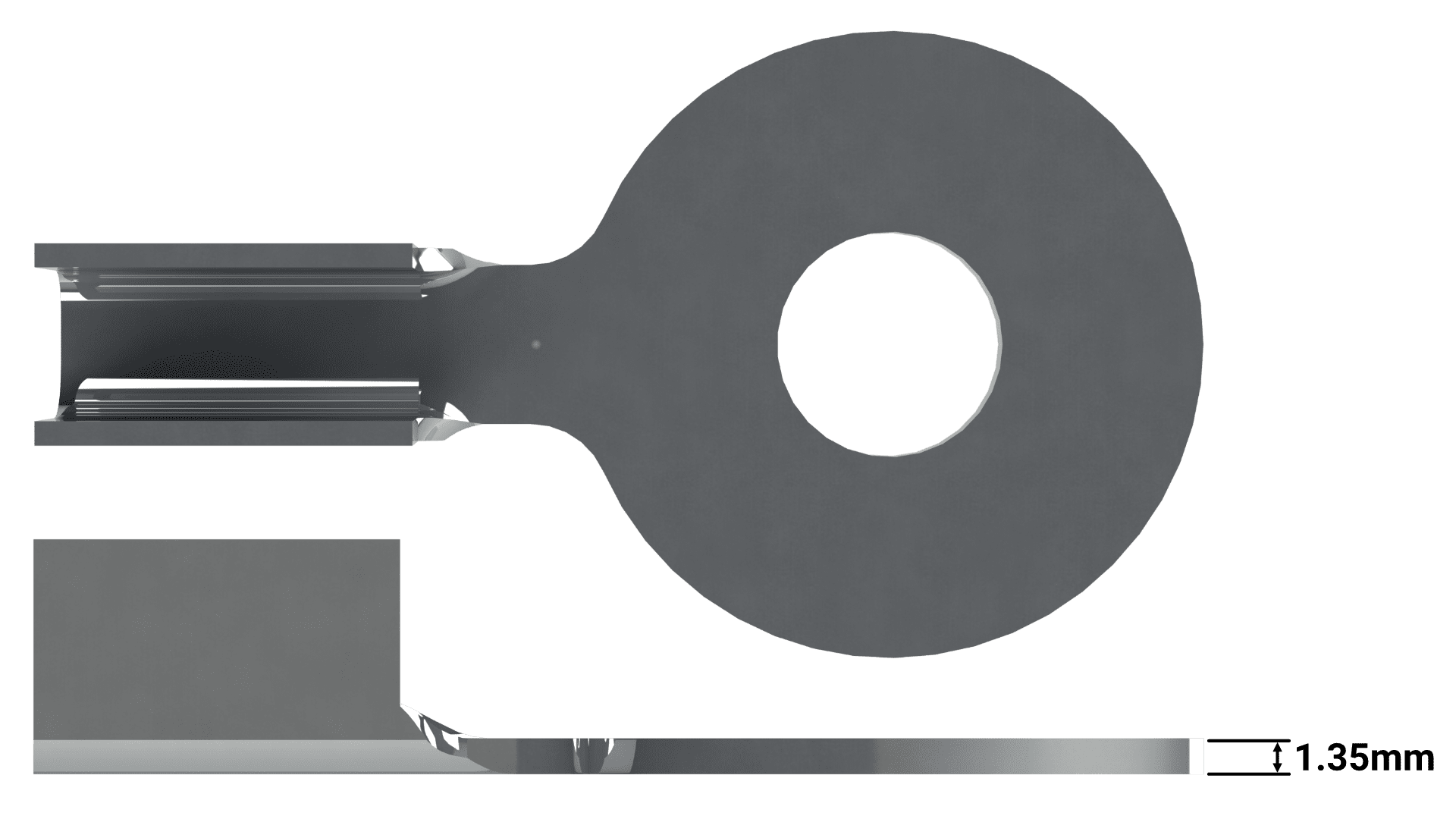

OptiClear Crimp/Seal 3/8″” Stud Ring Terminal 12-10 AWG from Würth Electronik

Design Notes

Common Types of Solderless Terminals

- Ring terminal, also known as a lug terminal, joins wiring to a stud or screw connection. One end of the terminal is equipped with a closed or open crimp barrel to make an electrical connection with the wire. The other end has a ring-shaped tongue installed on equipment by a bolt or screw that goes through the ring.

- Spade terminal (spade lug) or fork tongue terminal resembles a spade or a fork. It allows quick and easy connection or disconnection because the screws and bolts only need to be loosened, rather than removed.

- Hook terminals have a conductive hook on one end and often have an insulated sleeve on the other end, although non-insulated versions are available.

Material specifications

Solderless terminals may conform to UL, CSA, and MIL-Spec certifications.

EDAC IATF 16949 Certified Ring Terminals can be crimped onto electrical wires for a secure and reliable connection. These terminals are commonly used in automotive and electronic systems to facilitate efficient and corrosion-resistant electrical connections.

EDAC IATF 16949 Certified Ring Terminals can be crimped onto electrical wires for a secure and reliable connection. These terminals are commonly used in automotive and electronic systems to facilitate efficient and corrosion-resistant electrical connections.

Physical properties

Terminals are typically tin-plated copper.

Insulation is usually vinyl or nylon. Vinyl isn’t affected by humidity, whereas nylon can become brittle. Heat-shrink insulated terminals hold up to water, salt, corrosion, and heat. They have an inner wall lined with a hot-melt adhesive, inert at room temperature. Wires are easily inserted into the splices and terminals. When the sleeve is heated, the adhesive melts to form a tight, moisture-repellant seal that offers abrasion and chemical resistance.

Wire stops may be included in insulated and non-insulated terminals to prevent over-stripped wire from being inserted too far into the terminal.

A pull test is common for testing terminals attached to wire. This can be done with a device that clamps the wire, pulls at a set speed, and uses a load cell to measure force, or by hanging fixed weights on the wire for a specified time.

Weidmuller USA offers a wide range of insulated and non-insulated cable lugs and connectors, as well as tubular cable lugs according to current market standards (euro-series).

Markets and Applications

Industrial, Automotive, Consumer (appliances), Transportation (Marine), and others.

Suppliers

Molex, TE Connectivity, Waytek, 3M, Würth Electronik, Phoenix Contact, Weidmüller, Carlisle Interconnect Technologies, JST Corporation

Like this article? Check out our other Meet the Connector, Wire and Cable, and our Transportation Market Page, and our 2023 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024