Testing is Vital for Electronics Performance and Reliability

From chips to connectors, from qualification to production, testing is a necessary step to ensuring that electronic components function as expected.

We all love our technology until it doesn’t work properly or at all. When a tool or convenience that we’ve come to rely on fails, it’s frustrating. Sometimes, however, equipment failure is a matter of safety, even life or death, as with military applications, medical equipment, or ADAS (advanced driver assistance systems) in our automobiles. In some instances, reliability is a matter of longevity; on a satellite deployed in space or an underground oil rig, for example, there is no easy or timely way to fix faulty electronics. Ensuring that electronic components will function as expected requires testing.

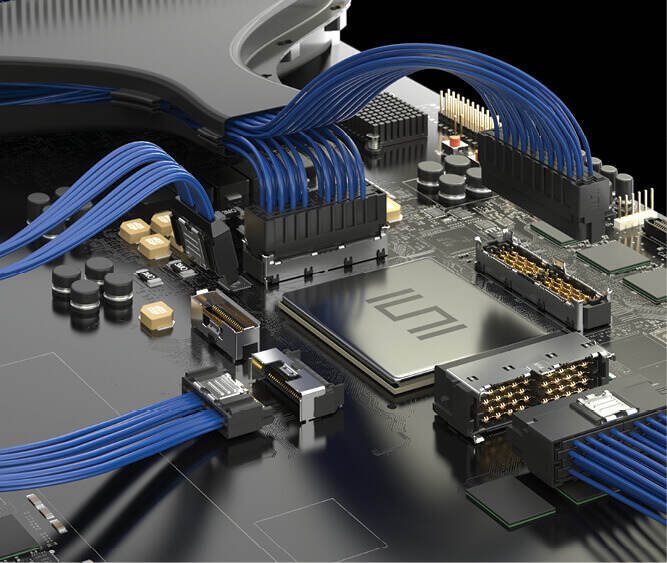

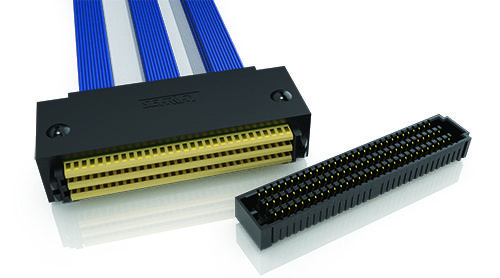

Samtec test solutions include a broad line of cost-effective, high pin count, extreme performance/density, and high mating cycle interconnect solutions. Shown here, cable systems for testing high-density and extreme performance systems.

Testing electronics occurs at different stages of design and production. It takes different forms and addresses various needs and aspects of functionality. Connector suppliers are involved either by providing products for testing equipment or by testing the products they provide to their customers.

Chip testing with ATE

Hundreds of billions of integrated circuits (ICs) are produced globally each year and each one is tested before it is incorporated into an electronic device. This requires an efficient and reliable test and verification system. Automatic test equipment (ATE) is used in the semiconductor industry to test ICs and their individual components (resistors, capacitors, and inductors). These systems are incredibly large and complex in order to accommodate the volume of product being tested. They require connector and cable assemblies that are specifically designed to meet those needs.

Samtec SEARAY™ high-speed cable system (SEAC, SEAF) used in test applications.

“The two constants we face regularly in developing products for the companies that make this equipment are increased bandwidth and increased density,” said Adam Linderman, head of business development, Samtec Inc. “For every new generation of memory that comes out, the stack from the memory producer typically increases twofold, from say, 32 GB to 64 GB, and so on. They always require more bandwidth, and they always want to double the amount of density they can test at one time, without increasing the footprint at the same rate. The same footprint must accommodate twice the amount of I/Os — twice the number of lanes, if you will, at double the data rate.”

The whole test apparatus, therefore, needs to be upgradeable at that rate as well. Either the interconnect must be designed to meet the requirements for upcoming design iterations, or it must be completely reconfigured with double the megabytes, Linderman explained. “This means 256 lines of coax are needed to test every I/O for 256 megabytes of memory. The increased density is within the same physical form factor. But on the back end, we’re going to have to increase the density of the connector itself, typically. Our challenge is fitting enough I/Os into a cable assembly connector.”

Testing for the design phase

Connectors often undergo testing to ensure they will meet specific customer requirements. This typically includes mechanical testing, environmental testing, signal integrity testing, electrical testing, and chemical testing. Depending on their final use, testing is often done to meet required standards or qualifications (MIL-spec and EN standards, for example) for a particular connector type, application, or environment. Connector companies may perform testing for qualification of their own parts or for customized parts they design for their customers. Every aspect of the connector needs to be approved, from the contact, the insulator, the housing to the whole assembly.

The goal behind all these tests is to simulate the complete life of the connectors, anticipate all failures that can possibly occur, and create the product that is best adapted for each application.

“The Mil/Aero market represents 80% of our activity and is one of the most exacting markets,” said Jorris Martel, test engineer at Nicomatic. “The slightest mistake can have serious consequences. Extensive precautions are taken for all projects in this market and we always work in a spirit of cooperation rather than in a typical client/supplier relationship.”

For example, in the case of a custom project, he explained, during the qualification all the results are given to the customer at weekly meetings. If any issues arise, a decision can be made quickly. In the case of a catalog product, the qualification is based on the customer’s needs. The results are shown to the customer at the end of the qualification and possible modifications of the product itself or of the qualification test plan are discussed and agreed upon.

Types of laboratory testing

Mechanical testing measures tensile strength, mechanical strength, contact engagement, separation force, insertion force, retention, and ingress protection (IP).

Environmental testing subjects the connector to different temperatures for a certain amount of time to test how it performs in heat or cold (temperature cycling) or when transitioning from one temperature extreme to the other (thermal shock). “For example, you test at 100 degrees for 30 minutes, and then you adjust the temperature to 50 below zero for 30 minutes,” said Martel.

Environmental testing also addresses dry and damp heat and cold, magnetic permeability (the proportion of the induced [internal] magnetic field and the applied [external] magnetic field strength), and resistance to conditions such as salt spray and shock and vibration. “Salt spray testing shows the effectiveness of our surface treatments,” said Martel.

Chemical testing includes fluid resistance (drag), marking, and silicon elasticity/expansion. Electrical tests include dialectic withstanding voltage, breakdown voltage, insulation resistance, and low pressure.

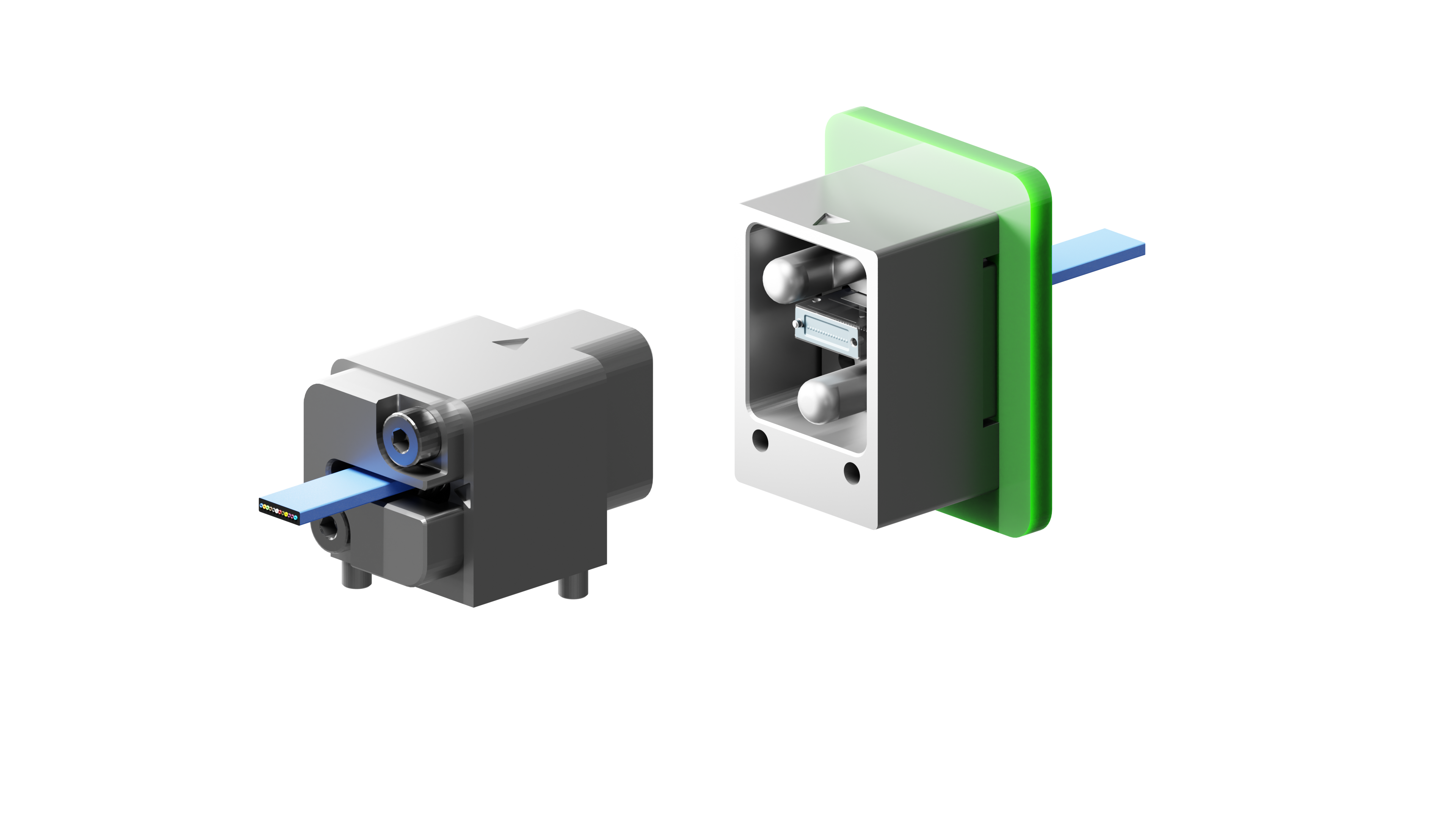

Nicomatic’s VITA 66 connectors are the result of successful testing by the company’s lab.

“New for our lab is testing optical fiber,” Martel said. “Nicomatic is currently working on optical connectors (VITA 66). We measure insertion loss and perform every kinetic mechanical test and environmental test on optical fibers. The project was a real success because we have added our new optical connector, “Ori,” based on VITA 66.4 standard, to our catalog. The journey does not end here because we are currently working on our second optical connector based on VITA 66.1.”

Signal integrity testing includes coaxial and differential signal, standard protocol communication, and time and frequency domain. “My specialty is electromagnetism, which concerns high-speed connectors — the maximum frequency that can be put in the contacts. The goal is always the highest frequency. For that we use VNA (vector network analyzer). We send a signal at different frequencies from, in our case, 100 kilohertz to 20 gigahertz to measure the attenuation of the signal. The goal for us is to create the perfect contact, the perfect conductor, and no attenuation, but that’s not possible,” said Martel.

“We test, also, different communication protocols, depending on the customers’ requirements. For example, a lot of our customers use JESD204b, USB 3.1, SATA 3, and much more. And they need us to be compliant with these. We can also help our customer to create his own ‘pin out’ on his connector in order to improve the performance of his system. The real goal for me is to guide and advise the customer to transform his project for success.”

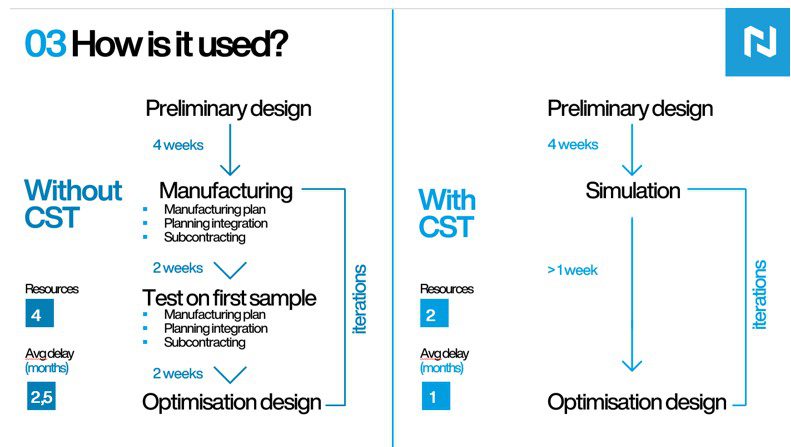

Martel and one of his colleagues are tasked with implementing the electromagnetic simulation in the group. “The purpose of the simulation is the possibility to create a new product in a short period of time,” he said.

Testing is a necessary process in the electronics industry. In some cases, testing to a standard or to meet a particular customer need is all that is required, given the time available and the requirements of the application. In critical markets, such as MIL/Aero and automotive safety, testing to failure is necessary. This means pushing the limits to ensure reliability, performance, durability, and safety beyond what is required.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for Samtec Inc. and Nicomatic.

Like this article? Check out our other Test & Measurement, Mil/Aero Market articles, and our 2024 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- M-Type Connectors Product Roundup - May 14, 2024

- May 2024 Connector Industry News - May 14, 2024

- Testing is Vital for Electronics Performance and Reliability - May 7, 2024