Field Wiring: The Backbone of Complex Industrial Environments

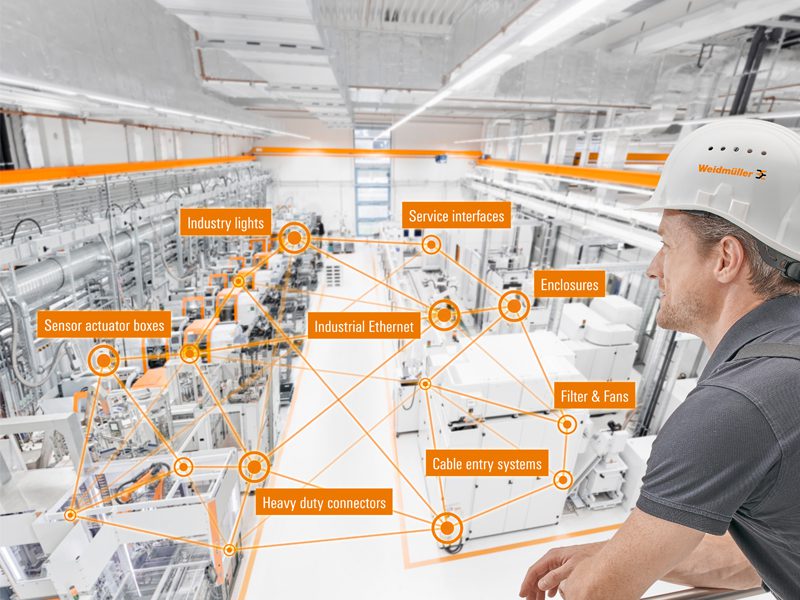

A consistent infrastructure, from the control cabinet to the field, can create significant added value in terms of efficiency, safety, and flexibility of production and automation processes.

Networking automation and control technology is an important aspect of wiring in the field, also known as field wiring. At the highest technical level, this is a smart system for transmitting controller and sensor data in industrial applications. In addition, it serves as the backbone of modern industrial networks, which include almost all aspects of a production facility or process control system.

As a comprehensive solution, it offers the option of connecting and integrating all electrical and electronic components, from sensors to actuators, control units, or communication devices. This allows for comprehensive monitoring, controlling and optimization of industrial processes. Field wiring not only ensures efficient data transmission and communication, but system reliability and robustness as well, helping to make real-time decisions based on precise data.

Heavy duty connectors (HDCs) take care of all power distribution needs to ensure communication. At the same time, pre-assembled solutions reduce the work required, as do technologies for quick and reliable connections in the field.

In a world where Industry 4.0 and system networking play a more and more important role, field wiring – which helps companies meet the demands of increasingly digitized and automated industries – is particularly relevant. It serves as the basis for efficient management, flexibility, and future reliability in a complex industrial environment.

Careful selection of industrial field wiring products reduces downtime and facilitates expansion, upgrades, and repairs.

Increasing modularization, which is ever more essential for tapping into greater potential effectiveness and efficiency, further elevates the importance of field wiring. When looking for a partner in field wiring, companies should look for maximum performance, minimum downtimes in field wiring as well as industrial field wiring experience that has been well-established in factory automation, machine construction, and intralogistics, particularly in the challenging IP67 environment.

Decentralization and modularization as key components of industrial field wiring

Decentralization, digitalization, and modularization are the key components influencing efficiency and flexibility in industrial field wiring. Decentralization means that controller and communication components are installed closer to the processes or systems themselves. The advantage of this approach is that cabling is shorter and more customized, saving space and reducing costs. For decentralization, you want to consider solutions such as fieldbus and Ethernet modules that facilitate seamless integration into field wiring and improve flexibility and scalability.

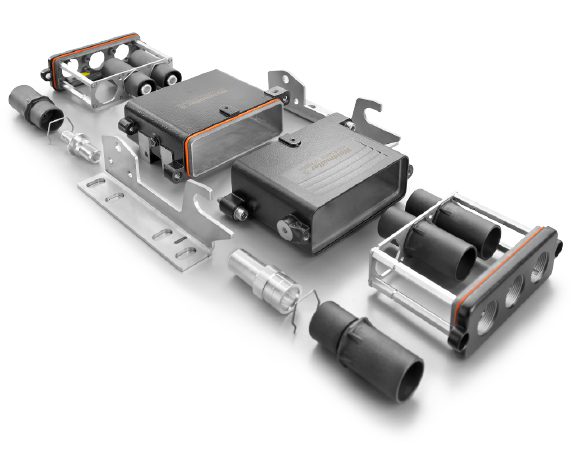

Modular solutions such as the RockStar High Power high current connectors deliver flexible, reliable performance in harsh environment industrial applications.

When it comes to modularization, now we look at the use of standardized, exchangeable components and modules to simplify system design and maintenance. These would range from plug-in connectors to sensor-actuator boxes, cable entry systems, and housings that make customized solutions possible and are reusable and flexible for users. This helps reduce downtimes during maintenance work and makes systems simple to update. Overall, decentralization and modularization improve the overall efficiency of field wiring and simplify maintenance, helping meet the demands placed on industrial wiring systems.

At the end of the day, field wiring solutions should comprise a complete product line for the field level. Everything that connects systems together – just like the nervous system in one’s own body.

The backbone in detail

A successful field wiring solution includes these elements:

- Heavy duty connectors. Robust industrial connectors that are resistant to extreme industrial or climatic conditions as well as electromagnetic interference.

- Connection lines, patch cables, and cables

- Circular connectors. PP-protected circular connectors in sizes M8, M12, M16, M23, and 7/8″ ensures reliable cabling for a system.

- Single-pair Ethernet plug-in connectors. Pre-assembled connectors for copper and fiber optic cables suitable for field assembly ensure reliable data transmission in your Ethernet networks.

- Industrial lights

- Filter fans

- Cable entry systems. A flexible cable entry system speeds up installation, facilitates service, and minimizes downtimes. Assembled and unassembled cables in control cabinets, housings, and machines should be reliably sealed and protected against tensile stress.

- Housing solutions. They must be able to adapt in the best possible way to the conditions facing the electronics and at the same time meet the requirements of the various industries from modular and small to profile housing.

- Industrial Ethernet. Industrial Ethernet components are the ideal connecting links for data communication between Ethernet-capable devices in building automation. These could range from switches for the efficient forwarding of data traffic, to industrial WLAN devices for the wireless connection of end devices, to routers for the protection of networks.

John Froustet, Director, Device & Field Connectivity Division Americas, Weidmuller

Why field wiring matters

Industrial field wiring is a crucial aspect for the optimal functioning of production and automation systems in industry. With the integration of Industrial IoT and the associated data volumes, the complexity and demands on field wiring are growing. Modern industrial field wiring solutions are characterized by high modularity and plug-and-play capability. This enables fast installation and commissioning while reducing downtime during maintenance. An end-to-end infrastructure creates significant added value in terms of efficiency, safety, and flexibility of production processes.

Visit Weidmuller to learn more about field wiring solutions.

Like this article? Check out our other articles on Automation, Ethernet, and our Wire and Cable Assemblies Market Page, and our 2023 and 2024 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Field Wiring: The Backbone of Complex Industrial Environments - March 26, 2024

- Battery Connectors: The Unsung Heroes of BESS Applications - August 15, 2023