What is MIL-Approved Wire/Cable?

What is MIL-Approved Wire/Cable?

MIL-approved wire, or MIL-spec wire, is any wiring solution that meets the strict standards developed for use in military applications. As with any military specifications, MIL-approved wire is designed for high performance and high reliability in harsh environments, which also makes it an attractive option for many non-military harsh environment applications.

Uses for MIL-approved wire

MIL-approved wire is ideal for high-frequency computerized applications in extreme temperatures. It must withstand demanding field conditions for long periods of time without failure. This includes shock and vibration, friction, and exposure to water, chemicals, and abrasive materials such as dirt and debris. It is used as ground wire, in aircraft, in heavy-duty vehicles that travel over rough terrain, and antenna connectivity.

In addition to being waterproof, fireproof, and chemical-resistant, MIL-approved wire must be functional in military vehicles and machines that require high circuit density. It must be resistant to damage from heavy footwear and equipment, meaning it can’t easily fray and its housing must be equally robust.

Non-military uses

Industrial heavy-duty machinery, equipment used in harsh environments, manufacturing machinery, commercial transport vehicles and civilian aircraft, and equipment used in oil and gas field operations.

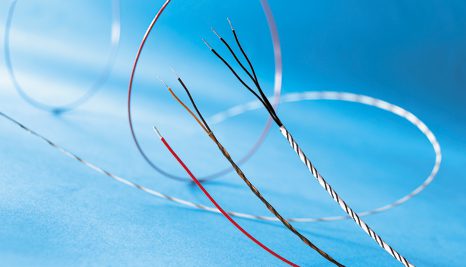

TE Connectivity’s SPEC 55 low-fluoride (LF) wire and cable. The MIL-spec cable’s specialized wire insulation system offers five times the scrape abrasion requirement under that standard.

Custom Design Options

MIL-approved wires are highly customizable within the parameters of MIL-Spec standards. They can be made from iron, gold, silver, or other material types. Special features like curve-friendly flexibility or custom endpoint terminal connectivity can be incorporated into their design.

Popular MIL-approved wire categories

- M22759 (SAE AS22759) Designed for aerospace applications, specifically aircraft engine controls and electronic systems and SWAMP (severe weather and moisture prone) areas.

- M16878 (MIL-W-16878 or NEMA HP3 and HP4 spec) Made with insulation materials such as PVC, PTFE, Polyalkene-PVC, and ETFE in thin, medium, or heavy wall thickness to withstand extreme temperature and voltage ratings, these are designed for specific products, for example M16878/4 is for harnessing, appliance wiring, and power supply, while M16878/5 is for electronics exposed to extremely high temperatures.

- M25038 For use in harsh environments with vibration and direct flame exposure, making it suitable for critical circuits used in aircraft.

- M13486 For cables used in low-tension military applications such as in military trucks, tanks and other ground vehicles, these wires are also resistant to moisture and abrasion and are flexible even at low temperatures.

- M5086 Features a tin-plated copper conductor insulated by PVC and a nylon jacket making it appropriate for applications where impact, abrasion, cut-through, or chemical exposure are likely and is used in a wide range of military, aerospace, and industrial electronic applications.

- MIL-W-81381 Designed for aerospace and widely used in commercial applications due to their high temperature rating and resistance to abrasion and solvents.

- MIL-W-81822 (SAE AS81822) Have solid conductors for wire-wrap termination, with extruded insulation of PTFE, PTFE with polyimide hardcoat, or ETFE. Each insulation type is available with one of three silver-plated conductor materials rated at 300 volts.

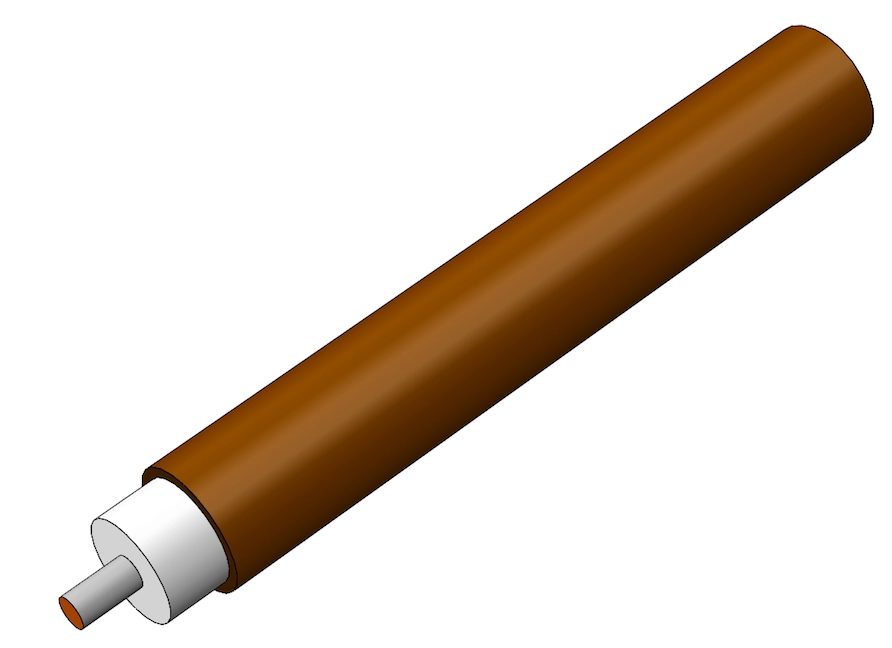

- MIL-C-17 For coaxial and twin coaxial cables. These radio frequency cables are flexible and rigid.

EZ Form, a Trexon company, offers 27 copper and aluminum jacketed semi-rigid cables qualified to MIL-DTL-17.

Design Notes

Secure connections are especially important in military applications. One way to prevent wires from coming loose is to make sure the sizing of the endpoint is compatible with the wire. Low-profile terminals fit through small openings and securely connect to the wire to its destination.

Applications

- Military and Aerospace: in aircraft, in satellites and launchers, in heavy-duty vehicles, ground wire, antenna connectivity, machines, equipment

- Commercial/industrial: heavy-duty machinery, equipment used in harsh environments, manufacturing machinery, commercial transport vehicles, civilian aircraft, oil and gas field equipment

Axon’ Cable supplies wires and cables in compliance with ESCC standards for the space industry designed to meet the challenging requirements of launchers and satellites.

Suppliers:

Related products:

- Hook-up wires

- Cables

- Cable assemblies

Like this article? Check out our other Meet the Connector and Wire articles, our Wire & Cable Assemblies Market Page, and our 2023 and 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024