Armor Up! Ruggedized, Shielded, and Armored Cables are Ready for Duty

Copper and fiber cabling runs through the grittiest environments and powers the most rugged electronic applications with the help of protective armor.

Behold the armored cable! When rugged conditions are at hand, armoring is ready to protect the wires or fibers inside of a cable —and ultimately protect the entire system. This heroic feature is specified for cables that are exposed to constant harsh environment conditions, such as a submarine communications cable or down-hole drilling equipment. It’s also there for intermittent hazards, such as busy event setups where vehicles could run over cables. Armored cable is the ideal solution for industrial, military, or outdoor applications.

In some situations, a cable conduit will do the job. Conduit is a metal or PVC tube through which cable can be routed. When conditions get rough, the conduit takes the brunt of the abuse, not the cable. In contrast, armored cable has protection built right in, and provides installation flexibility that conduit cannot. The wire or fiber conductors are bundled and insulated and then wrapped in a durable sheathing layer, which helps to shield the internal components from damage due to physical stress, moisture, or other environmental factors. Another layer of armoring, such as steel jacketing or a wrapped layer of galvanized (GI) wire in a helical twist, makes it much more difficult for anything to affect the conduit inside. Another PVC layer typically sheaths the entire cable, depending on the manufacturer and application requirements.

Hydro Group, a Trexon Company’s armored cable is constructed with a helical wire wrap, which forms a tight protective layer. The company is able to produce diameters ranging from 6 mm to over 80 mm and length quantities ranging from a 200 meters MOQ up to 20 km, depending upon specific component requirements.

Common armor types includes steel armored cable, which provides excellent protection against physical stress and damage; aluminum armored cable, which is typically lighter and more flexible than steel armored cable but may not provide as much protection; interlocked armored cable, which features a helically wound interlocking metal strip that provides a high degree of flexibility and resistance to physical stress; and sealed or liquid-tight armored cable, which features a layer of waterproof material that provides ingress protection (IP).

Amphenol RF’s ruggedized product portfolio, available from Mouser Electronics, includes new IP67 sealed BNC and TNC cable assemblies. These assemblies feature an innovative flexible PVC conduit that is used to wrap the length of the cable to provide an extra layer of protection in rough environments.

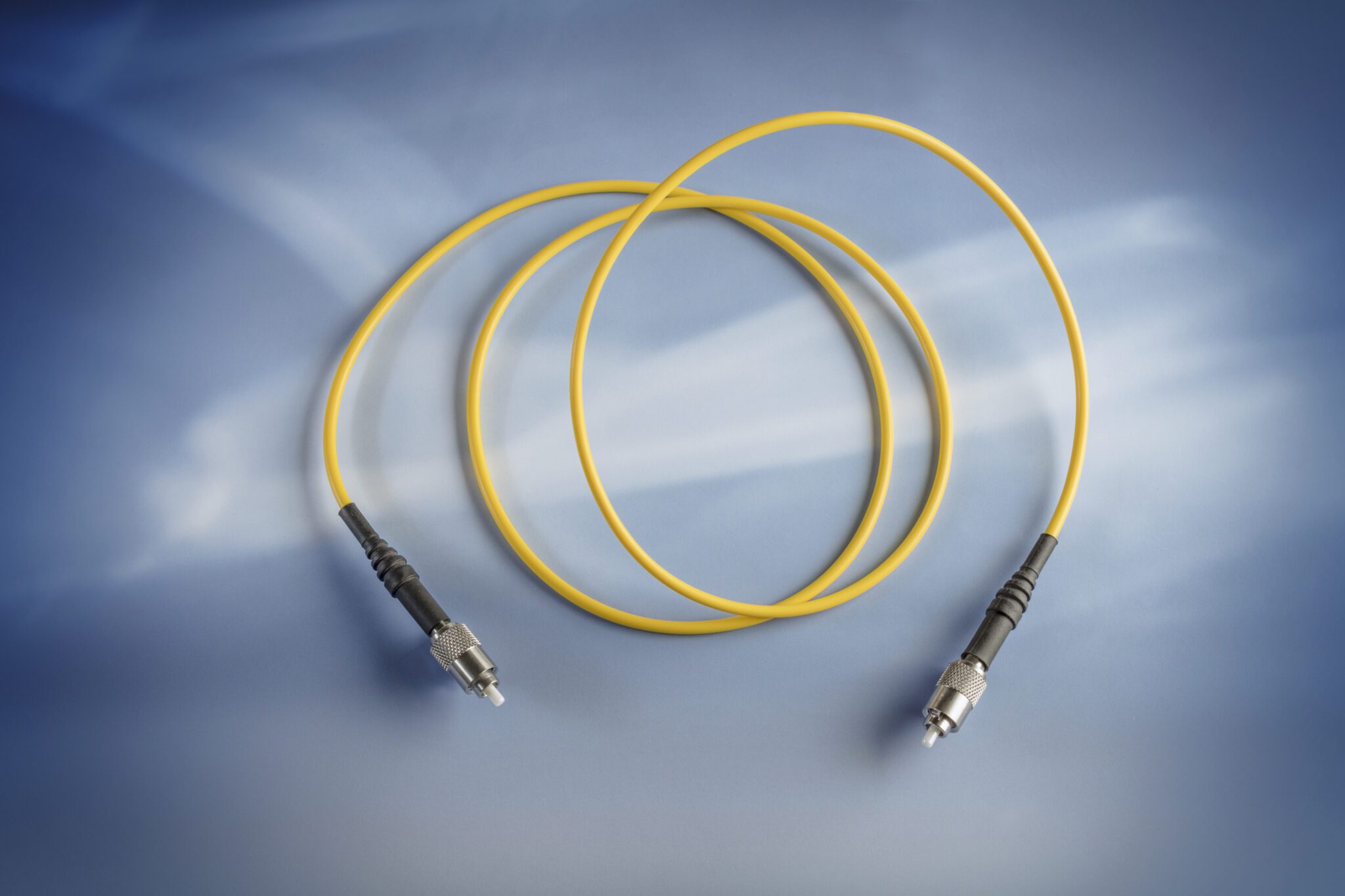

Armored cable can be used with both copper and fiber optic cables. The application requirements will determine whether armoring is needed, but it’s an especially good choice for fiber optic cables because delicate optical fibers are more fragile than copper and require additional protection against physical stress. Even small amounts of damage to a fiber optic cable can significantly degrade the signal quality and potentially cause data loss.

Greene Tweed’s FC-Fiber Protec and ST-Fiber Protec single fiber cable assemblies can withstand high temperatures while maintaining mechanical characteristics. A 900 µm buffered fiber is surrounded by an armored stainless-steel jacket to withstand crush and pressure situations while maintaining flexibility and durability.

It’s worth noting that the type of armor used with copper and fiber optic cables may differ. For example, steel armor is often used with copper cables because it provides excellent protection against physical stress, while aluminum armor is more commonly used with fiber optic cables because it is lighter and more flexible, which is important for maintaining the proper bend radius of the fiber optic cable.

Expanding need for armored cable

Trexon’s Hydro Group began producing armored cable after noting a growing customer need. “We had an opportunity a number of years ago to acquire machinery which was required for [helical wrap] processes,” said Ian Stuart, design engineer with Hydro Group. This equipment buy allows the company to expand into armored cable products for rugged industrial applications such as renewables, military equipment, and oil & gas operations. Stuart says the product is now widely used in applications such as static and dynamic power cables, ROV winches, tow cables, electrical and hydraulic umbilical assemblies, as well as smaller data and signal cables.

“For seabed cable and umbilical, armoring can provide protection for installation, and in service, steel armoring can provide better protection for burial, either by rock dumping or placing of concrete mattresses. This also provides improved protection once installed, in case of rock movement or accidental impact damage, and the increased density of the cable can reduce movement of the cable due to water currents if the cables are not being buried,” said Stuart.

“Armoring can also provide a high tensile strength, making it more suitable where a long length is suspended during installation (for example feeding cables from ships down to the seabed). This strength is also necessary for various lifting or towing applications. It is also particularly useful where smaller cables are required to be installed external to machinery. Where these would generally be a much smaller, more delicate cable, these can also be armored to ensure significantly improved durability and lifespan of the cables, improving overall system reliability.”

Generally armoring is required from the start, but Hydro Group has had several projects where armor has been added to previous designs. “In these cases, we have provided this as either a complete in house manufactured product, or by processing armor over a customer’s existing products.

An armored guard

In addition to providing mechanical protection, armored cable also helps reduce the risk of interference or signal loss. The layers of armor act as a physical shield from RFI and EMI. It can also indirectly contribute to data security by protecting cables from tampering and unauthorized access. Some attackers may attempt to gain access to a network by physically tapping into the cables and intercepting data transmissions. Armored cable can make it more difficult for attackers to gain access.

CarlisleIT’s UTiFLEX is available with additional armor to guard high-reliability systems and extend service life. It provides excellent loss characteristics, outstanding phase stability, and superb flexibility compared to standard flexible cables — all without sacrificing mechanical integrity.

Steve Begley, RF/Microwave Product Manager for Defense & Space at CarlisleIT, says that the development of armoring options stemmed from rugged applications that would easily damage coaxial cable, particularly in the military and aerospace markets. Armor extends the assembly life and adds additional physical protection for rugged and high-reliability equipment. CarlisleIT’s UTiFLEX microwave cable assemblies are specified for phased-array radars, air and land-based electronic warfare systems, missiles, gimbles, flight-line testing, and UAVs. The product is already highly ruggedized but an armoring option takes it to the next level.

“Armor options are designed to support specific needs of individual applications. Some are ideal for outdoor use with UV and weather resistance capabilities, others for platform installations with abrasion-resistant shields,” said Begley. “Ours are constructed using a low or ultra-low-density PTFE dielectric coupled with fully shielded outer conductors and a unique connector attachment that withstands mechanical and thermal stresses far better than standard connectors.”

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for , Carlisle Interconnect Technologies, Greene Tweed, Mouser Electronics, and Trexon

Like this article? Check out our other articles on Cable, Cable Assemblies, our Wire and Cable Assemblies Market Page, and our 2023 and 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Meet the Connector: DIN Standard Connectors - April 16, 2024

- Software-Driven Radio Reinvigorates Old Technology - April 9, 2024

- What is a Busbar? - April 2, 2024