What are Twinax Cables?

Meet the Connector: Twinax Cables

Twinax cables are specifically designed for improved performance in high-speed data applications. Compared to coaxial cable, which has a single conductor, twinax cable improves signal integrity, speed, and bandwidth by incorporating two conductors in its design.

“The main benefit of twinax over micro coax is its ability to transmit a high-speed differential pair with very low intrapair skew between the positive and negative signal of that differential pair,” said Andy Shrout, Samtec. Skew is the time delay difference between the positive and negative signals of the differential pair. Intrapair skew refers to the skew within the pair itself, rather than between two differential pairs. “With the sophistication of the silicon today — the chips, FPGAs— the skew difference from pair to pair is becoming less and less of a concern, but that intrapair skew, the skew within the differential pair itself or within a single twinax, is still extremely critical. It’s becoming even more critical as data rates get to 112 Gb/s PAM4 and looking at 224 Gb/s PAM4,” he added.

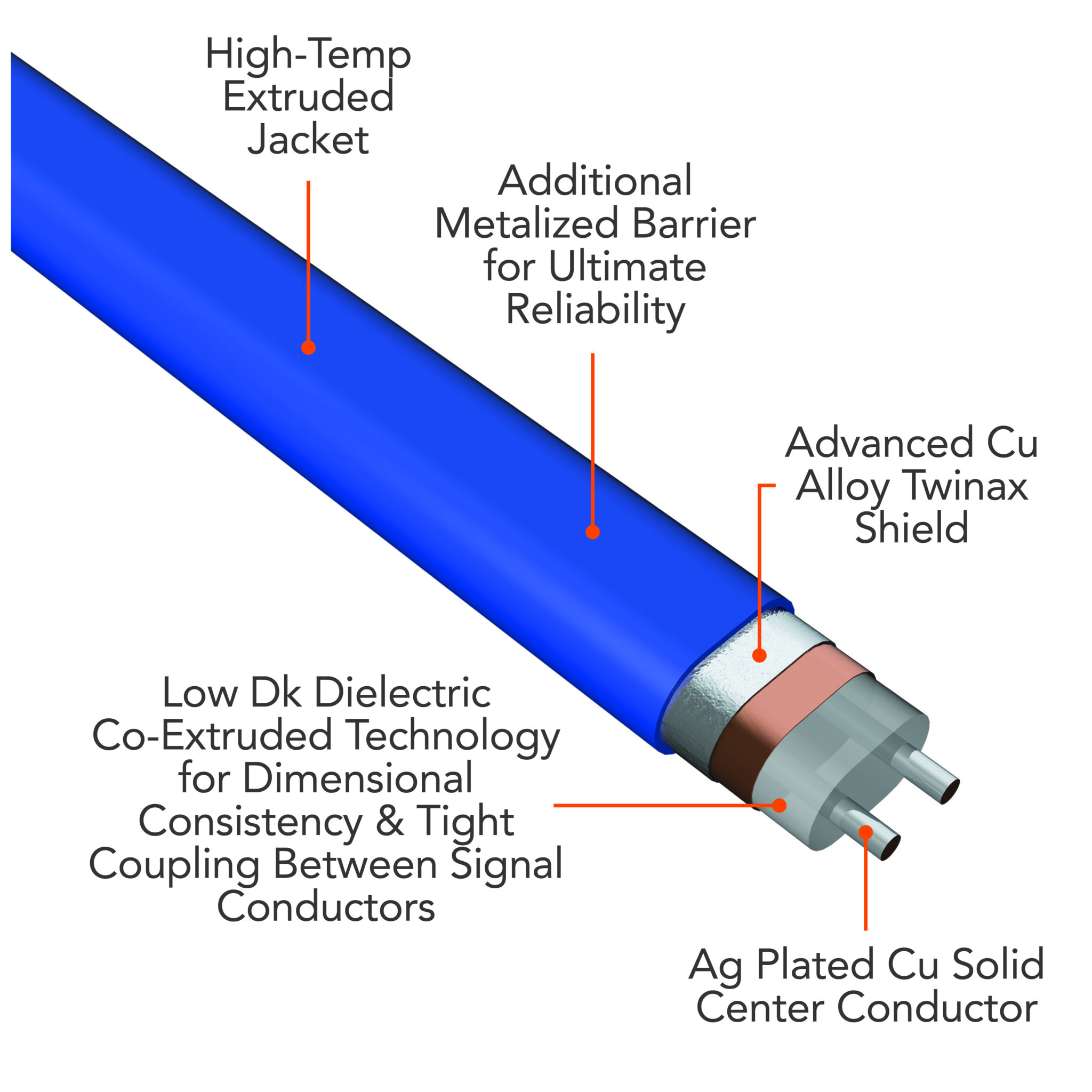

Twinax cable construction

Primarily four components make up a twinax:

- The inner conductors or signal conductors carry the signal. Twinax has one positive and one negative signal conductor.

- The dielectric is the non-conductive material around the signal conductors.

- The shield, used for ground return, wraps around the two conductors in the dielectric.

- The jacket, or outer insulation, covers the shield.

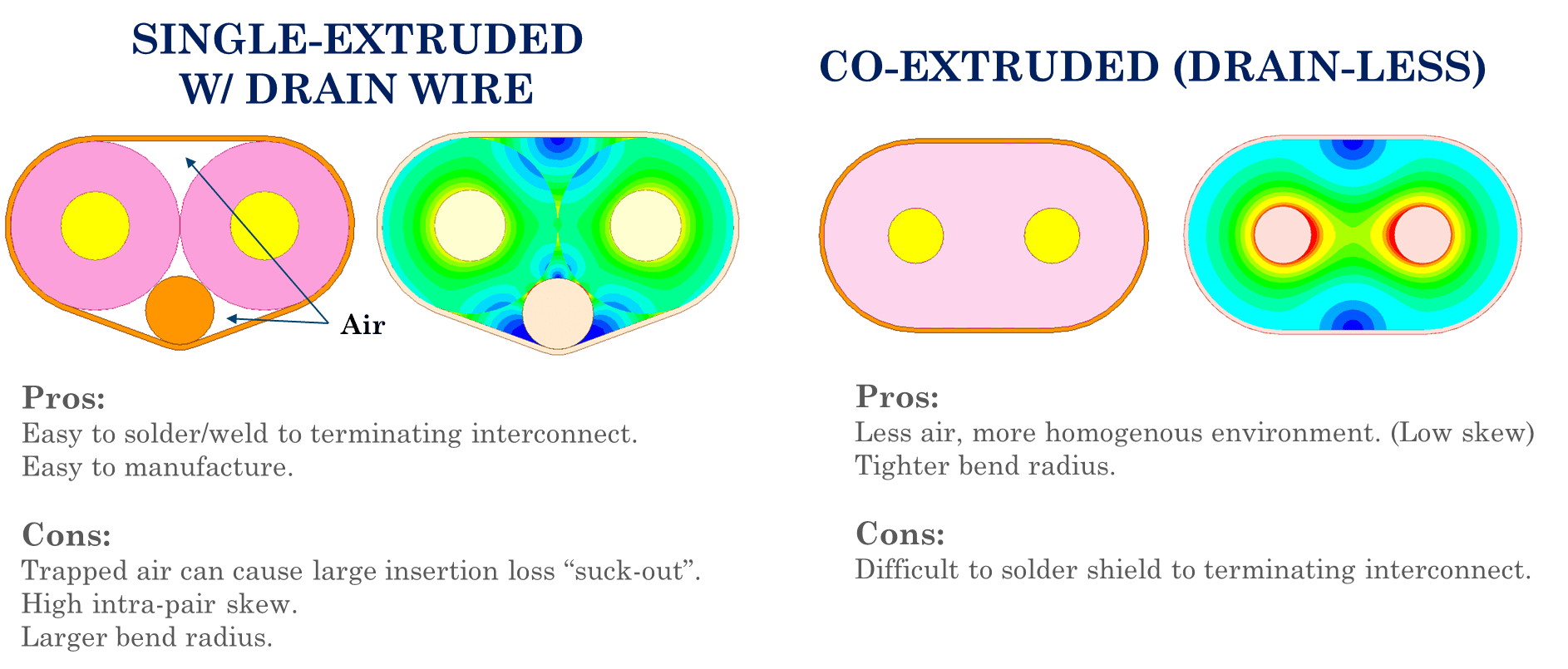

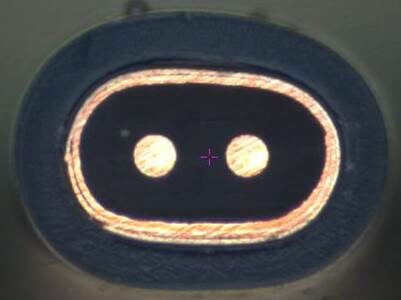

The structure of a twinax cable is what allows for that decrease in intrapair skew and the resulting improvement in signal integrity. In most twinax cables, each signal conductor is extruded into a dielectric (made of a plastic polymer or other non-conductive material). The two conductors wrapped in a shield creates that twinax structure.

Potentially, problems can occur if the conductors get out of sync or out of coupling. “That’s where you start to see a lot of bit errors, because your receiving chip cannot aggregate the positive and negative signals to determine the bit or the level of the voltage. If you’re using different materials, tolerances come into play that basically begin to create asymmetry within your transmission line,” said Shrout.

Samtec develops a unique twinax

Samtec entered the high-speed cable market 20 years ago with the vision of creating a twinax cable that supports the lowest interpair skew differential pair transmission line possible. Samtec’s twinax is fabricated with a unique coextruded dielectric technology. Two silver plated copper center conductors are simultaneously extruded into a single dielectric. The center conductors are precisely constrained relative to one another and relative to the shield (the ground return).

“Most twinax in the market today requires drain wires to bring the ground return path to the interconnect at the end of the twinax,” said Shrout. “With Samtec’s design, everything is constrained and there is no tolerance stack up. We’re able to maintain that extremely tight or low intrapair skew to where the signal propagating down the positive conductor and the signal propagating down the negative conductor stay very well coupled. They don’t get out of sync; they don’t get out of intrapair skew.”

Samtec’s coextruded twinax provides well matched impedance, extremely low intrapair skew, and an optimal transmission path for differential pair signaling.

Samtec’s design also eliminates the triangular air gaps on the top and bottom. Those air gaps present another opportunity for imbalance. “As you start to see different diameters of individual dielectrics, that’s going to change your air gaps, creating asymmetry in that transmission line. That becomes problematic at higher data rates. Any type of asymmetry in your transmission line is going to cause intrapair skew to rise. Another critical component to good twinax design is ensuring tightly matched impedance throughout the transmission line. Maintaining a constant structure with precise tolerancing will create a well-balanced impedance. This also helps improve both insertion loss and return loss characteristics. In addition, Samtec’s use of very low dielectric constant material (typically an FEP or a PFA material) results in more signal energy to the far end of the cable assembly,” said Shrout.

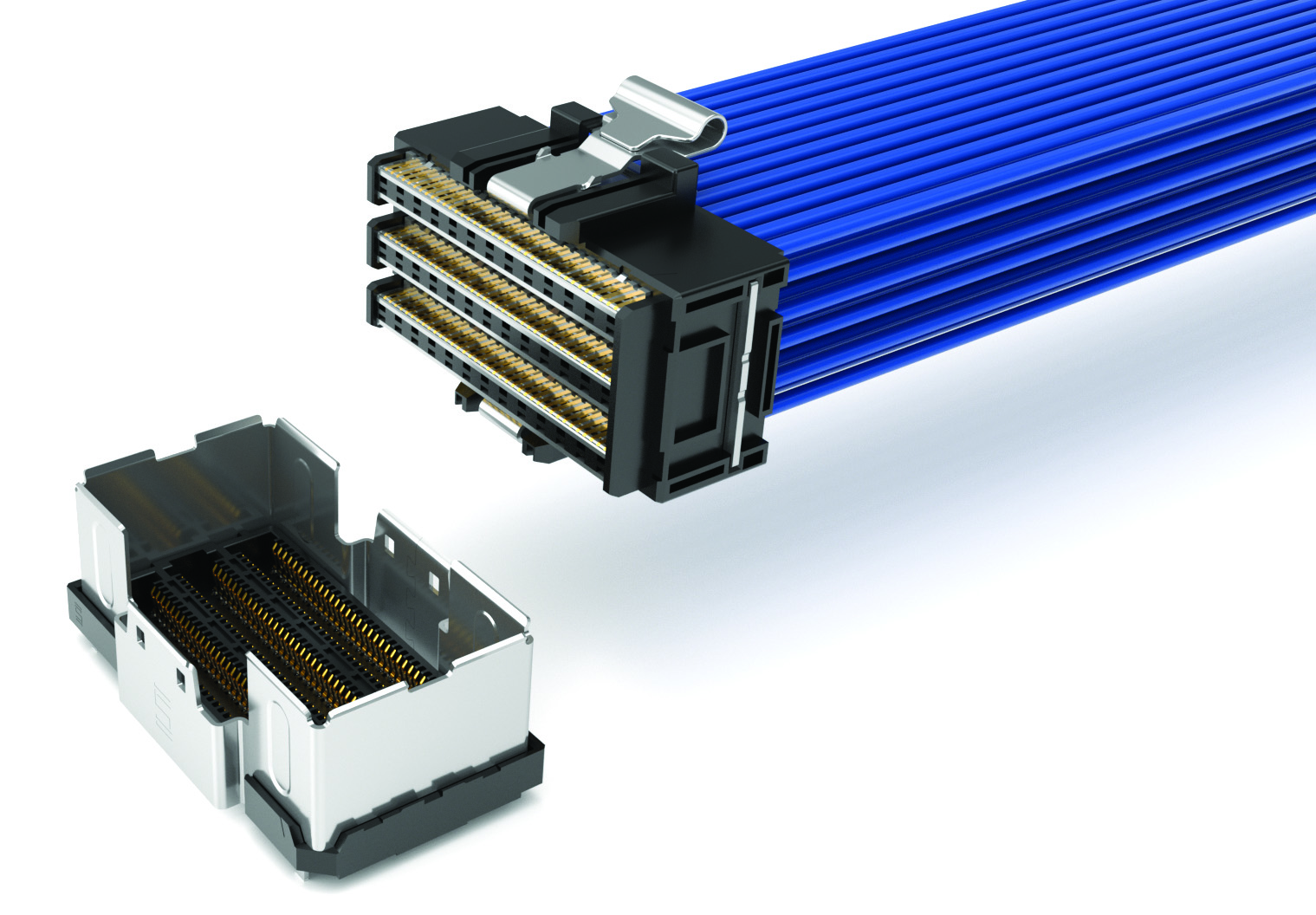

Samtec’s AcceleRate® HP cable product rated at 112 Gb/s PAM4 features ultra-low-skew twinax cable.

Twinax vs. coax

The primary benefit of twinax over coax occurs at higher data rates (5 Gb/s or above) and higher signal frequencies (2.5 GHz or above). As frequencies or data rates get higher and higher, the signals are propagating faster and faster. The receiving chip has difficulty recognizing that differential pair when it’s not coupled and that leads to a lot of bit errors.

Twinax vs. PCB

System architects and engineers use printed circuit boards (PCBs) to transmit differential pairs through PCB traces. Despite new materials with lower dielectric constants that help improve the signals to the PCB, at high data rates the PCBs introduce too much loss into the system to be able to get the signal from the transmitting chip to the receiving chip with enough energy to reduce the bit errors. Twinax cable flies the signal to the front panel or the backplane with very little loss.

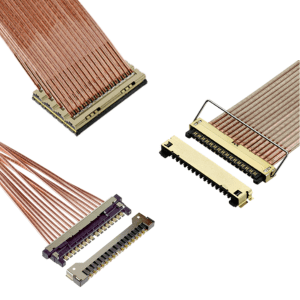

I-PEX’s DUALINE® 110-VB-M, DUALINE 195-HB, and DUALINE 130-HB-D twinax connectors (clockwise, from top left).

DUALINE is I-PEX’s series of twinax cable connectors suitable for ultra-high-speed transmission within enterprise computing applications, such as servers and switches. They operate at data rates of 112G PAM4 and higher. The twinax cables have two copper conductors surrounded by a dielectric and an external shield to maintain impedance control, reduce EMI, and mitigate crosstalk between differential pairs for better signal integrity. The compact, low-profile designs of the DUALINE connectors allow them to be used in tight spaces near the CPU or ASIC, even under its heat sink, contributing to the space-saving design of electronic switch boards. “With the ability to place the connector underneath the chip’s heat sink, we minimize the MLB trace loss in the channel and get as close to the chip as possible. Our LEAPWIRE® cable assembly can then directly connect to an external I/O connector, further minimizing the insertion loss of the channel and extending the reach,” said Ro Richard, senior signal integrity FAE with I-PEX.

Design Notes

Transmission lines The goal is balance, symmetry, well-matched impedance, low skew, and an optimal transmission path for differential pair signaling.

Material specifications Twinax cable is comprised of silver-plated copper conductors, non-conductive dielectric materials such as FTP or PFA, copper alloy shield, and a high-temp extruded jacket.

Markets and Applications Data communications and network communications; AI, supercomputing, and machine learning; the infrastructure evolution to 5g and mobile communications.

Suppliers Twinax cables are available from many suppliers, including Molex, Samtec, and TE Connectivity. Twinax connectors are available from Amphenol Aerospace, I-PEX, Samtec, Smiths Interconnect, and others.

Like this article? Check out our other Meet the Connector and High-Speed, our Wire & Cable Assemblies Market Page, and our 2023 and 2024 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024