Fiber Optic Advances Push the Bandwidth Envelope in Datacom

Network data communications has evolved rapidly from “high-speed” gigabit Ethernet LANs to the integration of cloud-based information technology and data streams demanding terabytes of data. Engineers at TE Connectivity discuss how fiber optic advances push the bandwidth envelope in datacom and drive the next level of capabilities.

Network data communications has evolved rapidly from “high-speed” gigabit (Gb) Ethernet local area networks (LANs) to the integration of cloud-based information technology (IT) and data streams demanding literally terabytes (TB) of data. To meet today’s and future demands, advances in fiber optic technologies and effective integration with copper networks are making it possible to accommodate the ever-increasing demands placed on enterprise voice and data communications systems while enabling reduced energy consumption.

But the demand for more bandwidth is nothing new. So what could compel a transition to fiber optics for both inter- and intra-system high-speed communications that has been predicted for more than 20 years? LightCounting, a market research firm focused on high-speed interconnects, reports in “Embedded Optical Modules” (May 2012) that “at 10Gb/s signaling, the problems were manageable, but as the industry transitions to 25G signaling, significant signal losses and issues are surfacing. As speeds increase to 25GHz, the number of signal-compensating electronics needed is skyrocketing along with costs.”

With its system advantages, fiber optics is destined to play an increasingly significant role in high-speed data communications. One system problem becoming increasingly critical is the airflow restriction with high-density copper cables. The amount and location of the openings in a typical faceplate design can have improved airflow and increased circuit board flexibility if fiber optics with significantly reduced diameter (as compared to copper cables) is used.

Beyond the faceplate connection, the implementation of mid-board optics further increases data capacity and further reduces the thermal issues in conventional architectures.

Taking the Heat Off the Faceplate

An emerging product segment has been created that allows system designers to embed optical transceiver technologies inside computer and communication systems. Embedding high-speed optical transceiver technologies, known as mid-board optics (MBO), onto traditional server line cards or switch fabrics allows system architects to achieve:

- Higher input/output densities

- Systems that are not bound by copper interconnect lengths

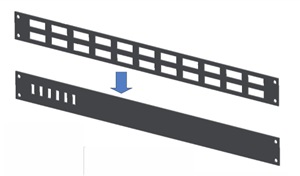

MBO inside systems mitigate the added electrical losses encountered at the 25Gb/s signaling rate. Figure 1 shows a comparison of faceplate density when optics move off the faceplate and onto the system’s printed circuit board. The top image shows maximum pluggable I/O density, based upon 400Gb/s CDFP active optical cable assemblies. The bottom shows the benefit if I/O is based upon optical connectivity. The optical solution results in substantially higher electrical I/O density while eliminating the cooling problem at the faceplate.

Figure 1. Conventional connection of optical cables to a data server faceplate (top view) creates both bandwidth limitations and heat dissipation problems. Implementation of mid-board optics will remove these restrictions (bottom view).

Mid-Board Optics

The mid-board optics module provides the key to eliminating the faceplate density problems and the attendant heat management problems. For example, TE’s MBO module (shown in Figure 2) is a 12-channel transceiver capable of transmitting and receiving 300Gb/s. The electrical interface is provided through a land grid array (LGA) socket on the optical module side and a ball grid array (BGA) on the host board, and allows modules to be placed on a one-inch grid. The high-speed inputs are DC-coupled to a floating input termination. On the Rx side, the incoming optical signal is converted to a current by the PIN diode. The output stage is current-mode-logic and provides 50 Ohm back-terminations.

Figure 2. Mid-board optics (MBO) modules, like the TE MBO shown here, provide the key to a high-density interface.

Advancing Optical Engine Technology

Advancing the capabilities of fiber optics to accommodate the demands for 25Gb/s and beyond will require application of innovative, high-density optical engine technology. TE Connectivity’s Coolbit optical engine represents just such an advance. This tiny engine satisfies both high-density and high-bandwidth requirements while running at about two-thirds the power of conventional solutions.

Faster and Denser Pluggable Optical Module

While the MBO configuration described above presents the ultimate solution to dealing with the higher data densities, active optical cable assemblies (AOCs) with embedded high-speed optics offer the benefits of optical with the ease of use of copper.

As an example, the TE CDFP supports 400Gb/s bidirectional data transport in a 16x25Gb/s configuration. It is a front/rear panel pluggable module that provides the highest density per panel area compared to other competing form factor products, resulting in the lowest watts per gigabits per square inch.

Another example is the TE QSFP28 (Figure 3) that supports 100Gb/s bidirectional data transport in a 4x25Gb/s configuration. It is a front panel/rear panel pluggable module that represents an I/O density of 240Gb/in2. Initial tests show a power consumption of 1.5 watts per end is achievable with all the signal integrity features enabled (channel equalizer, transceiver, and receiver clock data recovery).

Both CDFP and QSFP28 AOCs are built with TE Coolbit optical engine technology.

Figure 3. The QSFP28 Active Optical Cable utilizes TE’s CoolBit Optical Engine and supports 100Gb/s.

[hr]

This article was authored by Michael Tryson and Erin K. Byrne of TE Connectivity.