Built-in Circular Connectors in Medical Equipment Design

Built-in circular connectors save design time and cost in medical equipment systems.

Cell phones, laptop computers, and digital cameras all contain electrical connectors molded into their shells, with cables hidden inside hinges and shells and behind displays to save space, weight, and money. In the same way, medical instruments are designed so that standard elements of high-reliability connectors can be molded directly inside their parts. The medical industry has seen rapid evolution of digital electronics, sensors, and other components in items such as catheters, defibrillators, and monitors. As a result, patient monitoring, analysis, and life-sustaining services have improved significantly.

Today, we see more equipment that sends and/or receives electrical signals to and from the patient than could have been imagined a few years ago. New medical chip sets are capable of handling multiple input data channels, and they also provide wide ranges of display information, machine orders, and pump signals. To accomplish these functions, many new probes, sensors, and detectors have arrived with all their wiring, cables, and connectors as an integral part of the system. Until recently, cable harnesses with connectors were one of the larger and more challenging parts to handle in a medical instrument system. Sterilization or disposal of parts exposed to the patient was also difficult. To reduce these problems, integrated cable systems have become prevalent in electronic medical equipment.

Today, we see more equipment that sends and/or receives electrical signals to and from the patient than could have been imagined a few years ago. New medical chip sets are capable of handling multiple input data channels, and they also provide wide ranges of display information, machine orders, and pump signals. To accomplish these functions, many new probes, sensors, and detectors have arrived with all their wiring, cables, and connectors as an integral part of the system. Until recently, cable harnesses with connectors were one of the larger and more challenging parts to handle in a medical instrument system. Sterilization or disposal of parts exposed to the patient was also difficult. To reduce these problems, integrated cable systems have become prevalent in electronic medical equipment.

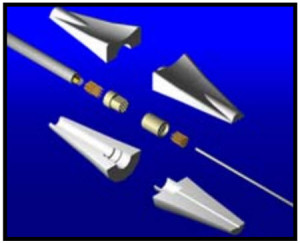

“Built-in” connectors are designed to be molded directly into medical equipment. Connector insulators are first assembled with pins or sockets that have been pre-wired or have solder lugs on the back. Mechanical assembly drawings are used to “size” and specify the internal fit of the overmold housings, handles, or probes that contain the connectors. Injection overmolding processes complete the final step of fabrication to form the final probe or handle assembly. There are many material options for the outer shell material, and selection is based upon the application. Materials range from the soft silicones to the white, hard, glossy shells used in tool handles.

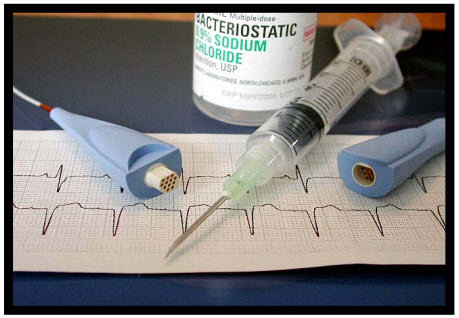

The perfusion monitor shown here includes built-in connectors in the probe assembly. This allows cleaning and sterilization of the machine while providing disposable attachments on the patient end of the electronic probe assembly. The insert portion of the miniature connector is overmolded into a design that serves as a connector as well as the handle for a small electronic probe. In this case, the end of the probe contains a “thermistor” element that changes electrically with variations of temperature. A surgeon can insert the probe into the body and continue to monitor the patient’s blood and tissue temperature during procedures. After the procedure, the patient end of the cable assembly can be disposed and the instrument cable disinfected for the next use. The micro circular connectors used in the design enable quick-change probes and sensors in the medical diagnostics world.

The perfusion monitor shown here includes built-in connectors in the probe assembly. This allows cleaning and sterilization of the machine while providing disposable attachments on the patient end of the electronic probe assembly. The insert portion of the miniature connector is overmolded into a design that serves as a connector as well as the handle for a small electronic probe. In this case, the end of the probe contains a “thermistor” element that changes electrically with variations of temperature. A surgeon can insert the probe into the body and continue to monitor the patient’s blood and tissue temperature during procedures. After the procedure, the patient end of the cable assembly can be disposed and the instrument cable disinfected for the next use. The micro circular connectors used in the design enable quick-change probes and sensors in the medical diagnostics world.

Standard building sets of circular insulators have alignment keys in the insulators to provide error-free mating and easy attachment. Socket shrouds protect pin-and-socket elements. Their design is aimed at achieving the highest reliability and ruggedness while maintaining the elements of simple, sturdy, and low-cost integration into instrument technology. The standard sets are used to begin the integration process. Design and assistance for molding the connectors into new medical equipment is readily available.

Built-in connector materials meet the highest test standards in the industry and are constructed using military-grade materials to meet medical instrument quality and reliability demands. The pins and sockets are made of annealed beryllium copper, are spring tension-controlled and then plated with nickel and gold. Circular insulators are molded using a glass-filled liquid crystal polymer that exceeds most temperature and chemical requirements in the industry. Teflon-insulated wires are pre-assembled or available with solder cups to allow factory-attach during equipment configuration.

Built-in connector materials meet the highest test standards in the industry and are constructed using military-grade materials to meet medical instrument quality and reliability demands. The pins and sockets are made of annealed beryllium copper, are spring tension-controlled and then plated with nickel and gold. Circular insulators are molded using a glass-filled liquid crystal polymer that exceeds most temperature and chemical requirements in the industry. Teflon-insulated wires are pre-assembled or available with solder cups to allow factory-attach during equipment configuration.

Instant prototyping is accomplished at the equipment level by hand-wiring “off-the-shelf” sets of the circular insert connectors prior to designing the mold. After final electrical and mechanical configuration is complete, the insulators are designed into their final shape and mating arrangement.

Medical applications using built-in connectors include laser tool handles, probes, sensors, electronic catheters, extended optical inspection devices, and even robotic instruments. Bone conduction hearing aids require light weight, small size, and easy mounting. Surgical tools and ultrasound equipment use integrated connectors to allow quick tool and head replacement. This results in a good design that is easy to use and reliable. Built-in connectors help equipment meet that goal.

New materials and processes have combined to improve and speed up design and fabrication of medical cable systems. As molded materials have evolved, liquid crystal polymers and others are significantly improving the chemical, physical, and temperature stability of connector insulators. This, combined with high-reliability pin-and-socket elements, has driven design into a simple sequence of overmolding current standard connectors and cables into a wide range of hand tools, probe systems, and electronic catheters. Many of these units have already passed the reliability and quality tests needed to achieve FDA approvals. Built-in connectors are a smart and efficient way to meet both performance and agency-approval demands.

Author Bob Stanton is director of technology at Omnetics Connector Corp.