What are the main coupling types for circular connectors?

Meet the Connector: Circular Connector Coupling Types

Circular connectors are a mainstay of applications in every market. They are durable, reliable, and available in a wide variety of sizes, materials, and form factors. This product category is highly diverse, with suitable options for many use cases and environments, yet they are all defined very simply by their cylindrical housing shape and circular mating face. To mate, both sides of the mating pair are pushed together and connect with pins on one side and sockets on the other.

Five main coupling types make the connection secure. The main five coupling types for circular connectors are bayonet, threaded, push-pull, snap-on, and screw-in coupling. “Coupling type” refers to the way two halves of a mating pair are secured. Circular connectors are use to connect a device to a cable or to connect two devices. Each coupling type offers specific advantages to users and applications. When specifying a circular connector, selecting the right coupling type depends on the application’s operating environment, power requirements, signal type, user access and skill level, and other factors. Each coupling type offers unique advantages.

ODU MEDI-SNAP 3.5 Touch-Proof High-Density Connectors, available from Mouser Electronics, offer maximum performance in small installation spaces for up to 41 signal contacts and are safe and reliable due to the push-pull locking system. The 3.5 connectors have unique inserts for hybrid solutions that provide space for more signals in addition to the transmission capability of power and fluids. Lightweight plastic housing, IEC 60601-1: 2 MOPP, 2 MOOP protection standards, and various media inserts are just a few of the features of MEDI-SNAP 3.5 connectors from ODU. Suitable environments for these connectors include industrial, medical, and Test & M easurement.

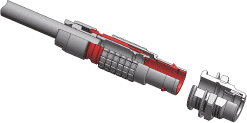

Bayonet Coupling: Bayonet connectors feature a plug on one side and a receptacle on the other. This type of coupling uses a rotating mechanism to lock the connector in place. Bayonet coupling is known for its reliability, ease of use, and high durability. It is commonly used in harsh environments where vibration and shock are present.

A variation, reverse bayonet connectors, was originally designed for NATO combat vehicles. Reverse bayonet connectors require a 120° turn to mate, enabling quick and easy mating and un-mating. Their design also allows the user to confirm mating in three different ways: tactile, audible, and visual. The user feels the connector lock into position when mated. A loud click is heard as the three studs snap into place when the coupling nut is fully engaged.

Tools: Bayonet coupling connectors do not typically require special tooling.

Glenair’s Series 80 Mighty Mouse Connectors from Mouser Electronics feature a bayonet coupling mechanism.

Threaded Coupling: This type of coupling uses a threaded mechanism to secure the connector in place. Threaded coupling is known for its high reliability and resistance to vibration. It is commonly used in applications where a high degree of protection against environmental factors is required.

Tools: Threaded coupling connectors are typically mated by hand, but some applications require a wrench to tighten or loosen the connector. It is important to ensure that the connector is tightened to the proper torque specification.

Amphenol Aerospace’s MIL-DTL-38999 features a threaded coupling mechanism.

Push-Pull Coupling: Push-pull coupling uses a simple push-pull mechanism to lock the connector in place. The connection is released by squeezing the connector body or pulling back on an outer sleeve to unlatch the pair. This type of coupling is commonly used in medical devices, sensors, and instrumentation applications. It offers ease of use and prevention of accidental disconnection in busy operational environments such as clinical settings.

Tools: Push-pull coupling connectors typically do not require any special tools.

LEMO invented the push-pull self-latching connector design in the 1950s. LEMO circular connectors, including IP-rated versions (available from Mouser Electronics), are widely use in medical applications.

Snap-On Coupling: Snap-on coupling uses a simple snap-on mechanism to secure the connector in place, and the connection is separated by pulling on the connectors. This type of coupling is commonly used applications where space is limited. It is known for its ease of use.

Tools: No special tools are required; the connection is made by hand.

Screw-In Coupling: Screw-in coupling uses a threaded mechanism to secure the connector in place. This type of coupling is commonly used in audio and video applications, such as RCA connectors. It is known for its high reliability and ease of use.

Tools: This type of connection is typically made by hand but in some applications, a torque screwdriver is used to tighten the connection to a specified torque specification.

Bulgin’s Buccaneer In-line Connector from RS features a screw-in locking mechanism.

Design Notes

Standardization: A wide variety of standardized products exist in the circular connector category, including MIL-DTL-5015, M-Type circular connectors, 38999s, and many others.

Markets, Sectors, and Applications

Automotive, Datacom/Telecom, Test & Measurement, Medical, Industrial, Military and Aerospace, 3C/Consumer

Suppliers

See Mouser Electronics for a full range of circular connectors.

Related products:

Like this article? Check out our other Meet the Connector, Circular Connectors, and our Transportation Market Page, and our 2022 and 2023 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Meet the Connector: DIN Standard Connectors - April 16, 2024

- Software-Driven Radio Reinvigorates Old Technology - April 9, 2024

- What is a Busbar? - April 2, 2024