Soldier Wearable Technologies Advance Military Operations

Wearable and portable technologies are giving soldiers superhuman strength, night vision, and powerful battlefield intelligence.

In conflicts around the world, soldier wearables and portable military technologies help military personnel enhance their physical capabilities, stay in contact with command centers and fellow soldiers, maintain situational awareness, reduce risks on the battlefield, and monitor their health. These technologies include assistive exoskeletons, night vision technologies, biometric monitoring devices, communications equipment, navigation and GPS devices, and tech-fused armor. As new technologies emerge and NATO countries increase their investments in military tactical and readiness programs, the global soldier wearable technology market size is expected to grow from $6.88 billion in 2022 $ 4.34 billion by 2028, a CAGR of 13.02%.

Connector suppliers are developing components to support these technologies, with a focus on high speed, high reliability, lightweight, miniaturized, and ruggedized properties to deliver performance in challenging military environments. Soldiers might carry as much as 120 pounds of equipment, making it essential that interconnects contribute as little weight as possible. Interconnects used in these systems must also comply with U.S. and NATO military standards. The GOSSRA (Generic Open Soldier Systems Reference Architecture), NATA STANAG 4695 power connector standard, an open architecture connector for soldier systems, and USB 3.0 are among the recent standards developments influencing interconnect selection.

Olivier Thormann, product manager with Fischer Connectors, said soldier wearables are an important focus for the company, which provides harsh-environment interconnects to military customers around the world, including products used in night vision goggles, GPS trackers, tactical radios, and power supplies. These interconnects have very strict requirements for ruggedness, as well as sealing, miniaturization, faultless data transmission, and low thermal and EMI/EMC signatures. “We work closely with customers to understand their requirements and needs to anticipate future programs to modernize soldier systems. Trends are always towards more power and data in a smaller form factor, but with increased density, solutions become more complex,” he said. “These systems generate a huge amount of data, which must be managed to avoid bottlenecks and bandwidth issues.”

Another challenge is compatibility. Military operations typically include fully functional yet older equipment. “We are in the middle of old and new systems. With NETT Warrior, for example, there are compatibility issues to overcome as new equipment joins legacy systems,” he said. Military equipment designers are also beginning to move from USB 2.0 to USB 3.0, an evolution that provides physical backward compatibility, enabling older equipment to retain functionality, while fully compatible new equipment is able to leap to faster data speeds.

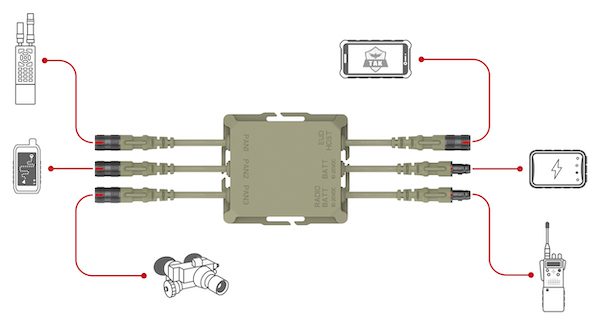

Fischer Connectors’ KEYSTONE hub enables soldiers to connect their body-worn devices easily and reliably, and to efficiently manage the flows of data (USB 2.0 and SMBus) and power (100 W, 5 A max) through a single source. It is controlled from an easy-to-use EUD power management app (as standalone or as ATAK plug-in) and integrates with a range of standard interfaces.

Fischer Connectors recently introduced its KEYSTONE data and power transmission hub with 6 ports, a next-generation tactical connectivity solution that allows soldiers to manage all wearable systems through a single unit that connects to an app. “KEYSTONE is robust to the bone in every aspect of its design,” said Thormann. “The electronics inside as well as the exterior package are designed for ruggedness and high performance. It is fully shielded for EMI/EMC and features high security firmware for data security. It has been rigorously tested to ensure performance in military field conditions, and each unit is checked at the end of the production line, including 100 electrical tests on every unit, ICT testing, continuity testing for signal and shielding, and rigorous sealing tests. There is no compromise on reliability in this product which has been engineered in our Swiss-based R&D Center.”

Interconnects aimed at the wearable and portable military market have potential use in numerous soldier products and programs, including:

–NETT Warrior (Network Enabled Tactical Technology), a state-of-the-art soldier wearable system that provides real-time information to soldiers in the field. Developed by the U.S. Army, this suite of technologies includes a ruggedized tablet computer that soldiers use to view maps, live video feeds, and other critical information. NETT Warrior also includes a wearable computer, helmet-mounted display, and a tactical radio system. The system coordinates with other soldier technologies, such as weapon sights and thermal imaging devices.

-Heads-Up Display (HUD) systems are incorporated into soldier helmets. Similar to those used in fighter aircraft, these technologies provide soldiers with a transparent display, overlaying critical information, such as navigation data, target identification, and threat warnings, onto their field of view.

TE Connectivity’s Mini-ETH cables are suitable for military headsets, biometric sensors, and other wearables. These miniaturized cables handle high frequency, high-speed transmissions in a lightweight format.

-Exoskeletons are wearable robotic devices that enhance soldier strength, endurance, and mobility. These rigid support frameworks enable soldiers to carry heavier loads, cover challenging terrain, and improve overall operational effectiveness.

Sensor technologies have enabled new biometric solutions aimed at monitoring soldier well-being with the goal of aiding mission readiness.

ITT Cannon’s MKJ Warrior Series offers a reliable interconnect solution that enables critical communication, navigation, and USB data/power for modern soldier applications. The MKJ Warrior Series provides a robust breakaway coupling system, designed per the US NETT Warrior specification and qualified to the European GOSSRA standard.

-The U.S. Department of Defense Rapid Assessment of Threat Exposure (RATE) project, a wearable device that uses biometric data to identify COVID-19 infections in service members before symptoms appear. The technology may expand to detect other infectious diseases.

-Biometric monitoring devices use sensors to track soldiers’ heart rate, body temperature, blood oxygen levels, and stress levels so commanders can make data-driven decisions to optimize soldier performance. These devices include integrated body armor infused with wearable technologies can incorporate sensors to detect and display vital signs, hydration levels, and the overall health of the soldier.

AirBorn’s Series 360 was designed specifically for the needs of soldier systems, with features such as quick push-pull disconnection, watertight sealing, color-coding and keying, and easy cleaning in a lightweight design.

Portable and wearable soldier technologies are supporting more successful and safer military operations. As development in these systems continues, the future of soldier wearable technologies holds immense potential to shape the landscape of modern military operations.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for AirBorn, Fischer Connectors, ITT Cannon, and TE Connectivity.

Like this article? Check out our other High Speed, Miniaturization, Mil/Aero Market articles, and our 2022 and 2023 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024