Smaller, Faster, Smarter: Miniature Industrial Connectors

Connectors are competing for space in today’s automated industrial processes. A next-generation miniature industrial connector format balances space constraints with data performance. Meet the iX Industrial.

At the 2018 Hannover Fair, HARTING identified miniaturization as one of six trends defining the evolution of integrated industrial processes. The others are digitization, integration, e-mobility, modularization, and customization. Digitization is significant in the industrial space, generating growth in smart devices and moving processing power away from data highways and into the field where intelligent components, such as cameras, sensors, and actuators, use high-speed Ethernet to spread the connected network.

The combination of miniaturization and digitization in the industrial sector has resulted in an increased network of vision systems and robotics. Cameras, monitors, and sensors are integrated into smaller spaces along the production line to gather information to improve quality and reduce downtime. “Data is everything,” said Kevin Canham, product and application manager, HARTING UK. Today, as Industry 4.0 becomes more commonplace, “virtually anything” can be monitored. One example: Optical systems can be used to identify and reject parts in the factory. “The more information there is, the better to control processes.”

Data Gathering

Sensors gather information, such as temperature, humidity, vibration, and light, to monitor all aspects of a production process or system. The data is collated and sent to the cloud for analysis or storage. Data transfer has to be at high data rates so that any problems can be identified and addressed in time to avoid or minimize disruption. If parameters are breached, then predictive maintenance can be administered at precise locations to reduce the length of downtime or stoppages in the production process.

Industry 4.0, also known as the smart factory or the networked industrial space, does not mean that all communications are wireless and that connectors are redundant. In robotics, data is sent to the robotic head to dictate the direction, angle, and speed of movement. Connectors are needed to transfer sensor data to the cloud for analytics, and they are also used to send signals for predictive maintenance. Canham said that the means to record data has evolved into smaller options, such as a Raspberry Pi board, a field-attachable computer, or HARTING’s Modular Industry Computing Architecture (MICA) computer.

“The higher data rates lead to better — but not bigger — connectors,” says Canham. For over 30 years, the industry has relied on the RJ45 connector, but it is simply too big for today’s flat mobile devices, displays, smaller automation equipment, cameras, and vision systems. RJ45 is also not robust enough for many applications; its locking tabs can be broken easily, causing contact problems. In response, HARTING and Hirose Electric have jointly developed an alternative, the iX Industrial miniature Ethernet interface.

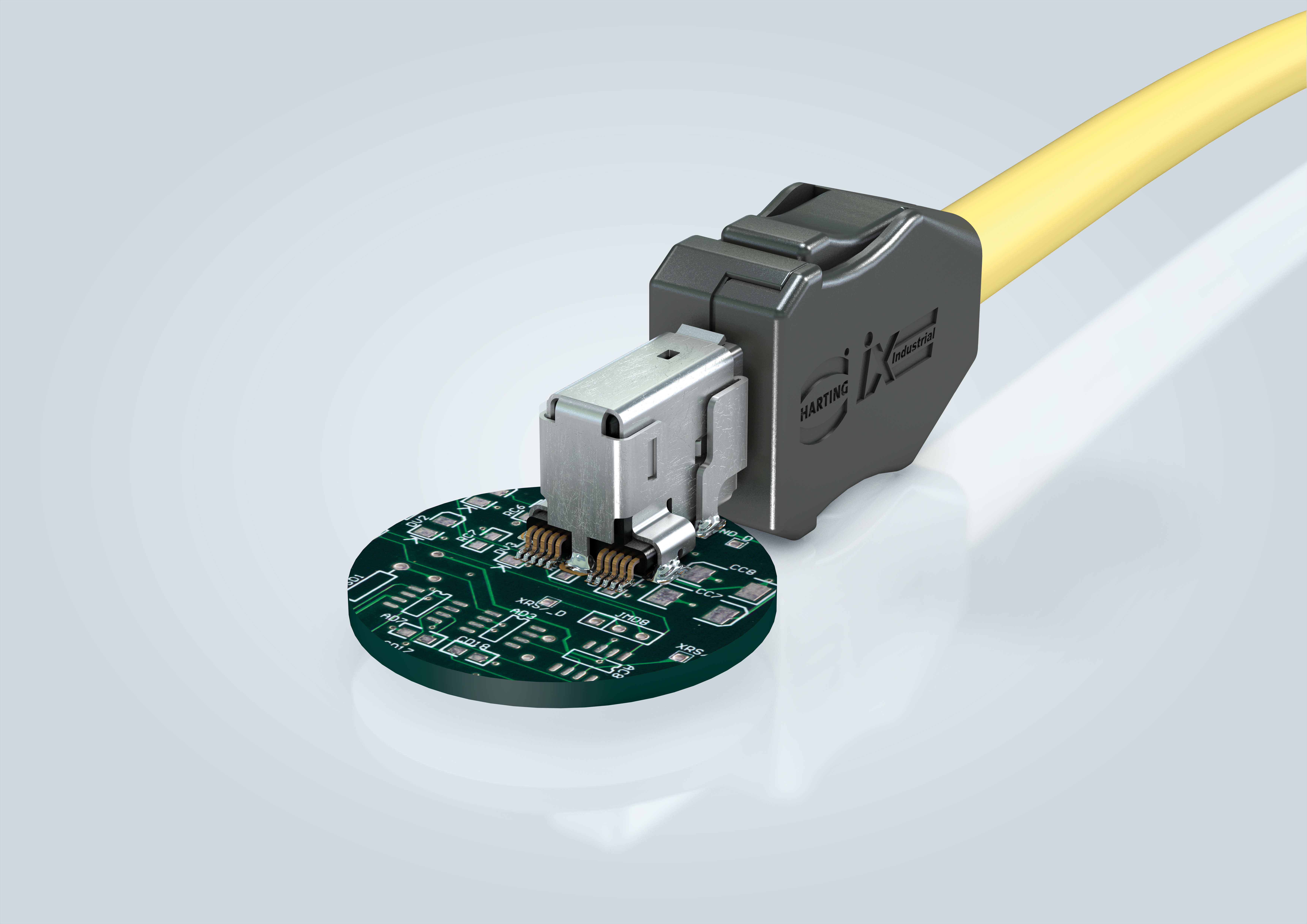

Demand for space-saving interconnection has led to the development of the iX Industrial connector.

The iX is an alternative to the RJ45 interface that is synonymous with Ethernet connections. “RJ45 is established, millions of connections — iX won’t supersede it, not for five to 10 years anyway,” says Canham. However, it is plugging some of the gaps where miniaturization makes the use of RJ45 connectors problematic. The iX interface is designed to the industry standard IEC 61076-3-124, which specifies the dimensions and mechanical, electrical, and transmission characteristics for industrial connectors. It reduces the PCB jack size by 70% compared to RJ45 models. It also combines power supply and data transmission in a single interface to save valuable space and meet the increased performance demands of today’s industrial environment.

Robust Design

To address the issue of robustness, the iX design replaces the plastic locking tabs of the RJ45 with two metal snap-in hooks. This structure is designed to ensure a strong connection, since one of the criticisms of RJ45 is that the plastic locking tabs snap off easily. The hooks provide a haptic feedback for a secure connection. The latches are incorporated into the metal can for shielding, which also boosts signal integrity.

The interface provides a vibration-proof connection for the cable to the PCB and has been tested for up to 5,000 mating cycles. The connector can also attach vertically or horizontally to the board, which can save space in the final product’s form factor, and especially in applications like digital signage, where the I/O’s position on the circuit board may be dictated by exterior factors.

Hirose’s iX Industrial Series connectors conform to the new IEC Standard IEC PAS 61076-3-124 for Industrial Ethernet connectors. They have a small, robust form factor especially designed for high-speed transmission in industrial environments. Like HARTING, Hirose is also working to grow the new ix Industrial standard product offering.

Five through-hole reflow (THR) shield contacts fix the socket to the PCB to prevent damage to the conductor tracks caused by exerting high forces on the socket. Additionally, Canham noted, a 360° shield provides high EMC immunity for data transmission. Another improvement is the crimp connection between the cable sheath and plug connection. Unlike RJ45 connectors, no screwdriver is needed to make the connection. Initially, the iX was terminated in the factory only, so HARTING introduced an insulation displacement contact (IDC) version. This requires a simple clamp tool to terminate the connection in the field.

Future Proofing

The miniature industrial connector has Cat 6A performance, future-proofed for 1–10Gb/s Ethernet operation, and its high current-carrying capacity enables both current and future Power over Ethernet (PoE) applications. The iX interface also meets EN50155 railway specifications for shock and vibration resistance.

In anticipation of a slow adoption rate, due to the proliferation of RJ45 connectivity, HARTING is already working on refinements for the interface technology. One example is sealing to IP65 to protect against dust and immersion in water. “It took many years to get magnetics and lights to show that signals are being transmitted onto RJ45; all these extensions are already planned for iX,” said Canham.

Other planned developments include Ethernet switch products that can be used with the iX, even though typical industrial automation switches are for the de facto RJ45 design. The iX Industrial is an open standard with DIN, IEC, and other standards bodies’ approvals. To offer it as a patented design would be “to shoot yourself in the foot,” said Canham. “An open standard means more copies for more deployment.”

Headers and Receptacles

Another company tackling the changing environment of automation and control is TE Connectivity, which produces the Ampmodu connector system and recently added a UL- and VDE-approved range of 2mm headers and receptacles, which save space in industrial equipment designs.

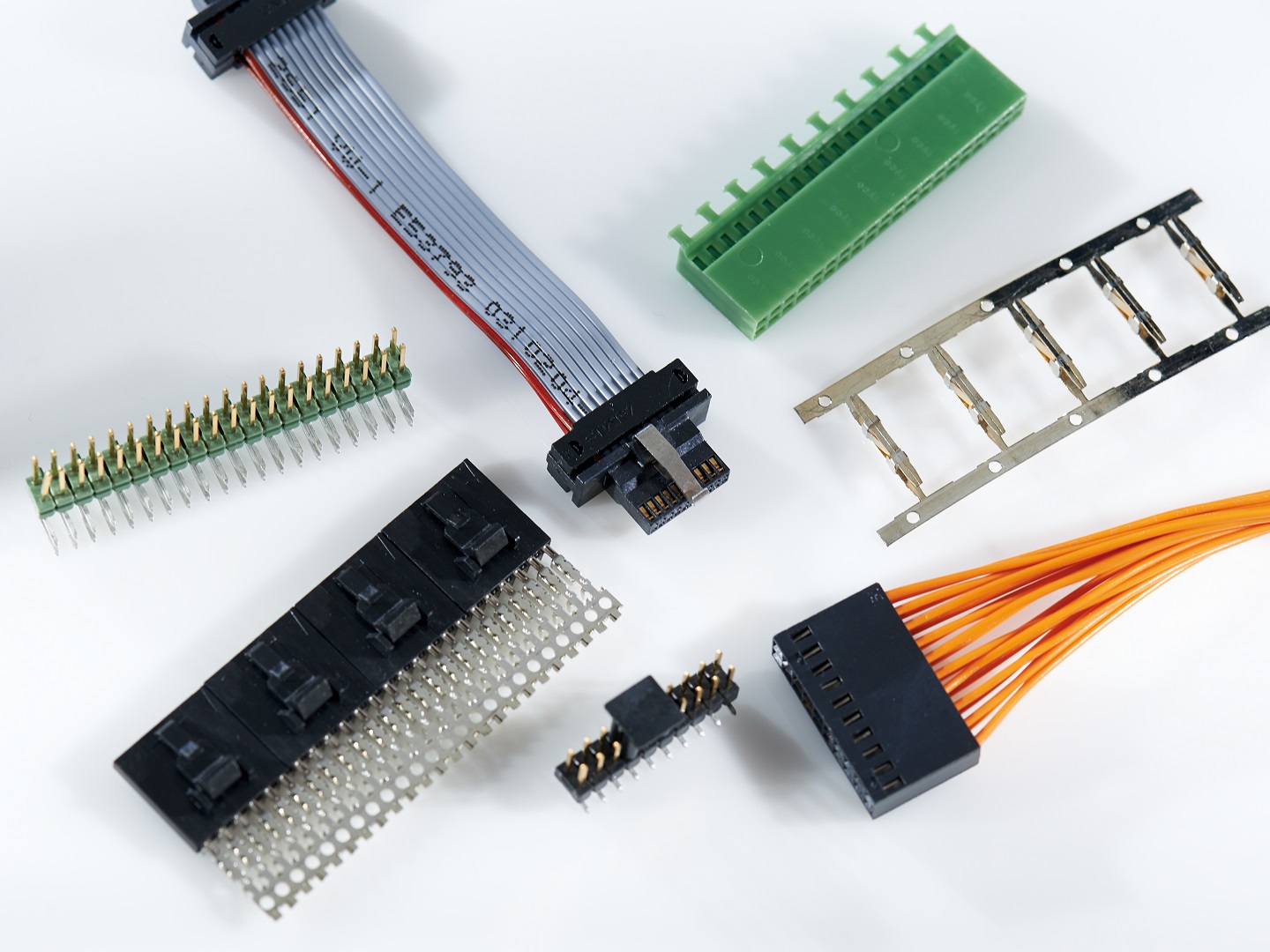

TE Connectivity targets industrial applications by adding 2mm headers to its Ampmodu connector system.

“The board-to-board (BTB) and wire-to-board (WTB) headers occupy over a third less space than headers with a 2.54mm centerline,” said Sameer Trikha, global product manager, industrial device – board connectivity at TE Connectivity.

The headers are available in breakaway, shrouded, and stacking versions that are suitable for automated surface mount technology (SMT), THR (pin-in-paste), and traditional through-hole mounting onto 1.2mm-, 1.6mm-, and 2.4mm-thick boards. The shrouded headers are intermateable with connectors from manufacturers, while a center-latching version is specifically designed for high-vibration environments. The company will also introduce mating board-mount and wire-applied receptacles later this year.

The Hirose EF1 series in-line power connectors handle up to 160A.

In addition to co-developing the iX interface, Hirose has also introduced the EF1 Series for industrial applications in which miniaturization and performance demands mean that the DIN rail mount, in-line receptacle and plug, and panel mount in-line receptacle and plug accept high-power crimp contacts and are able to accommodate up to 160A.

This design allows a crimped cable to be inserted into the connector housing in a single operation using a JIS C 9711 hand tool. Internal spring contact and contact points optimize contact force and a snap-in lock confirms the mating operation. There are also four mating styles to prevent incorrect mating when using multiple connectors in power controllers, inverters, robotic controllers, and other industrial equipment.

As industrial environments continue to adapt to take advantage of the efficiencies offered by the Industrial Internet of Things (IIoT), this new generation of industrial connectors will get into spaces the big ones cannot, with no loss of performance or power.

By Caroline Hayes