Six Considerations for Connectors Used in Marine Applications

Watercraft engineers must heed the American Boat and Yacht Council standards. Beyond these basics, keep six directives in mind to design reliable connected systems for even the roughest of waters.

By Rob Iversrud, Product and Category Manager, Waytek

Electrical connectors used in boats and other marine applications must meet exacting standards, especially when it comes to withstanding the effects of weather, water and saltwater, vibration, and temperature extremes. In addition, limited space is often a factor, calling for compact connectors or connectors with high pin counts to handle multiple wires.

The American Boat and Yacht Council (ABYC) maintains comprehensive standards for direct current electrical systems on boats. Within these standards are several connector-specific directives that can serve as a framework for understanding connector selection requirements.

1) Weatherproof and/or waterproof design

The ABYC stipulates that plugs and receptacles exposed to weather must be weatherproof and, if subject to immersion, watertight. Before purchasing a connector, check to see its Ingress Protection rating and make sure that it is capable of long-term performance under the intended conditions.

The ecomate Aquarius Series of waterproof connectors from Amphenol Sine Systems provides an IP67/69K waterproof rating along with multiple coupling options and pin counts ranging from 3 to 32 positions.

2) Non-interchangeability

Per ABYC, receptacles and matching plugs used on DC systems must not be interchangeable with receptacles and matching plugs used elsewhere on the boat for AC systems.

One way to prevent improper crossing of systems and connections is the use of color-coded wiring, a well-established practice in the marine industry. The ABYC provides extensive wire color-coding charts for guidance. In addition, some manufacturers provide connectors in multiple color options to support color-coding.

A green connector receptacle from the Amphenol Sine AT series, which offers housings in additional colors (including black, white, red, blue, brown, and yellow) to support color-coded wire and circuit identification.

3) Limited flexing

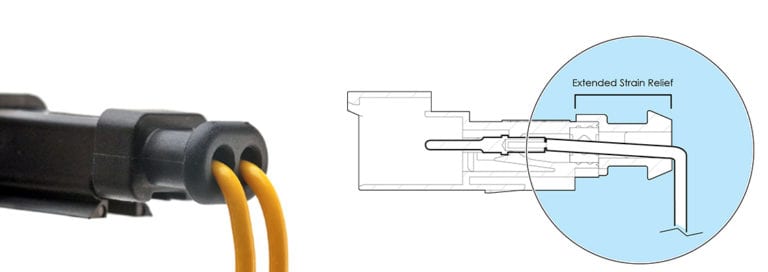

The ABYC states that plugs and receptacles must incorporate means for supporting all wires to limit flexing at the connection. Today’s leading connector manufacturers provide models with built-in strain relief in the form of extended housing to prevent wire bending.

A two-way AT series connector from Amphenol Sine Systems with built-in strain relief that prevents wires from bending where they meet the terminals.

4) Disengagement Force

Per ABYC, plug connectors shall have a minimum disengagement force of six pounds along the axial direction of the connector for one minute. This requirement is easily met and exceeded by many heavy-duty connectors in the marketplace.

A 12-Way ATM connector series plug from Amphenol Sine Systems with a locking tab that ensures a disengagement force far higher than the six pounds required by ABYC.

Connectors with self-closing snap-style covers or connector position assurance (CPA) mechanisms typically ensure the minimum engagement required to keep connectors from accidentally disengaging in marine applications.

An Aptiv Apex 2.8 sealed connector housing with a positive-locking connector position assurance tab visible at upper right (in red). When mating the connector, the red tab is pushed in to help ensure a tight connection with a high disengagement force.

5) Capacity

The ABYC states that the connector’s capacity shall be selected to meet or exceed the ampacity and temperature rating of the connecting conductors in addition to its wire size capability.

Make sure your connectors are rated to handle the current of the boat’s electrical system and the temperature of the operating environment. If current exceeds the connector’s capacity, it can increase resistance, cause component wear and tear, and lead to voltage drops, system malfunctions, or failures.

6) Short circuit protection

Per the ABYC, each terminal in a multi-wire plug and receptacle shall be protected from accidental short-circuiting to adjacent terminals. Today’s industry-standard multi-pin connectors are manufactured to maintain adequate separation of terminals inside the housing.

An AMP Superseal connector from TE Connectivity with separate pin slots for safe and effective wiring of adjacent terminals.

Meeting the Marine Challenge

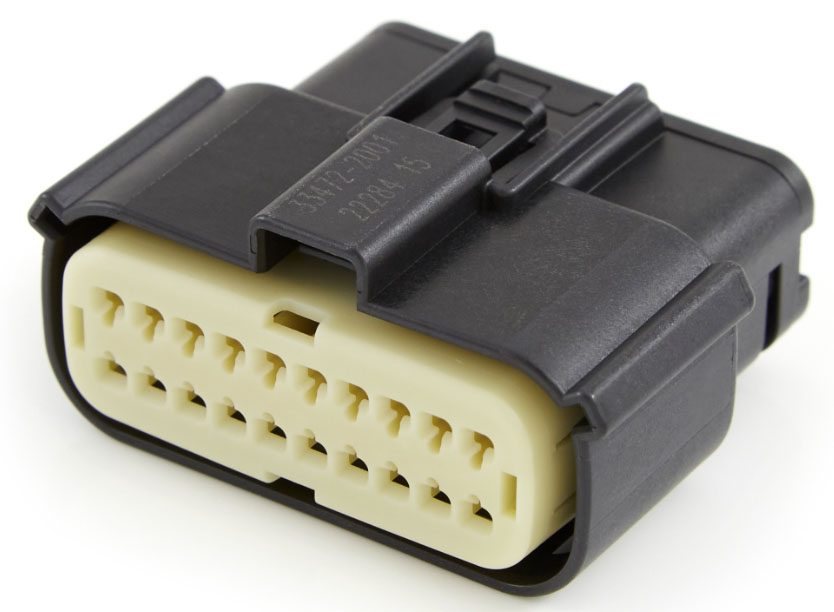

The ABYC’s specifications set the bar high for connector systems used in marine applications. Fortunately, connectors that meet or exceed these standards are widely available. In addition to the connectors mentioned above, other reliable options include heavy-duty connectors in the ATP Series and ATM Series by Amphenol Sine Systems, Weather-Pack and Metri-Pack connectors from Aptiv, and MX150 connectors from Molex.

A Molex MX 150 Series 20-pin connector body.

Anderson Power has announced that it will soon be launching a new IP68 waterproof series of connectors called SBS X-75A, which should be able to withstand submersion in 6 feet of water for up to 30 minutes. These connectors will come with strain relief cable clamps as well as metal latches to safeguard against accidental disconnects.

Connectors used in marine applications will typically have high IP ratings and operating temperature ranges, and will be constructed to handle shock, vibration, and exposure to corrosive chemicals and environmental conditions. Many of the connectors that are used for marine applications are also ideal for other demanding segments such as heavy-duty construction vehicles, off-road vehicles, and agricultural equipment. For more information, see the ABYC’s standards for DC wiring, review IP ratings for electrical components, and consult manufacturer specifications before purchasing connectors for marine use.

Like this article? Check out our other High Reliability and Waterproof articles, our Transportation Market Page, and our 2023 and 2024 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.