What are GTMS Connectors?

Meet the Connector: GTMS Connectors

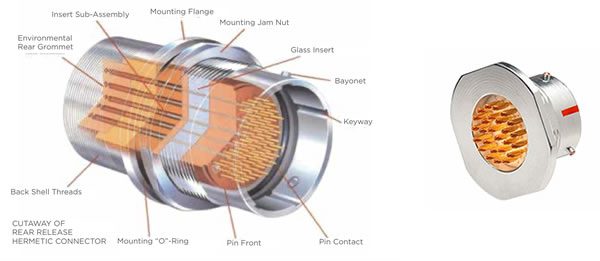

GTMS (Glass-to-Metal Seal) connectors are a specialized electronic connector with a hermetic seal between glass and metal components. They are used in high-reliability applications where electrical connections need to be made in environments that require protection from moisture, gases, or fine particle contaminants.

Glass is an excellent insulating material in electronics, bonds well with metals, and is corrosion resistant. It is also resistant to changes in temperature and pressure. The glass used in electronic sealing elements is made from a variety of ground or pelletized non-crystalline materials such as silicates, borates, and phosphates that are heated to melting point and then cooled to form a seal.

The construction of GTMS connectors typically involves a metal conductor surrounded by glass insulation, with the glass forming a seal around the metal conductor. This design creates a reliable and durable connection that is resistant to environmental factors such as temperature variations, humidity, and corrosion. Other attachment methods include using an O-ring to secure the glass seal or including glass in the insulation design.

Design Notes

There are distinct categories of glass-seal hermetics: Matched and mismatched (or compression) seals. Matched seal hermetics have a relatively limited thermal expansion and contraction of the glass and metal materials (usually within 10% of each other), which limits resulting the stress on the glass element. In mismatched seals, the thermal expansion and contraction of the metal is greater than that of the glass. In the manufacture of the connector, the heated metal expands and then cools upon the more stable glass to form an extremely tight seal.

The glass-to-metal sealing feature can be implemented into a variety of connectors, including common MIL-Spec standard connectors. Glenair offers GTMS versions of common standard connector types, including MIL-DTL-38999 (left) and MIL-DTL-83513/micro-D (right). These standard formats are commonly equipped with matched seals.

GTMS connectors come in a variety of types, including:

- Hermetic feedthroughs: Used to pass electrical signals, power, or fluid through a sealed barrier, such as a vacuum chamber or pressure vessel.

- Glass-sealed connectors: Used for high-reliability applications where electrical connections need to be made in challenging environments, such as in military electronics or downhole drilling equipment.

- Glass-to-metal seals for sensors: Used in sensor assemblies where electrical connections must be made while maintaining a hermetic seal to protect sensitive components from environmental damage.

Alternative Materials

Glass is a surprising effective and durable material in GTMS connectors. However, the inherent rigidity and brittleness of glass may lead to problems if the design does not properly manage tension and stress on the joint. Risks include voids, separation between the glass and the metal, or a breakdown in the structural integrity of the glass. The glass-to-metal seal not only has to survive the melting process during manufacturing but also must withstand the thousands of thermal cycles under actual operating conditions.

Greene Tweed offers a variation of GTMS that employs thermoplastic in the seal that traditionally would be glass. (See Greene Tweed’s analysis of these materials in the eBook Rugged Components for Harsh Environments.)

Markets, Sectors, and Applications

Datacom/Telecom, Industrial, Test & Measurement, Medical, Military and Aerospace

GTMS connectors are used for applications in harsh environment markets, including military (communication systems, radar systems, surveillance equipment, and weapon systems) and aerospace (avionics systems, satellite communications equipment, cockpit instrumentation, and missile guidance systems), automotive, transportation, medical (implantable medical devices, diagnostic equipment, and surgical instruments), oil & gas (offshore drilling platforms, downhole instrumentation, and subsea control systems), and industrial applications (robotics, programmable logic controllers, motion control systems, and sensors).

Hermetic Seal Corp’s GTMS bulkheads are designed for the severe operating conditions commonly encountered in oil & gas exploration and have been exposed to a combination of pressures and temperatures in excess of 25,000 PSI at 400ºF (204ºC). or 35,000 PSI at 500ºF (260ºC) for custom designs.

GTMS connectors are also utilized in various scientific instruments and laboratory equipment, where they protect sensitive components and maintain precise measurement and control capabilities.

Suppliers

Amphenol Aerospace, Amphenol Pcd, Glenair, Inc., Greene Tweed, Teledyne Reynolds, Hermetic Seal Corporation, Dietze, HiRel Connectors Inc., SCHOTT AG, Sealtron, Sussex Wire, Winchester

Related products:

- Hermetically sealed connectors

Like this article? Check out our other Meet the Connector and Networking articles, our Transportation Market Page, and our 2023 and 2024 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024