Choosing the Best Connector for Analog Sensors

Analog sensors gather data needed to track the activities and productivity of equipment, predict maintenance and make repairs, and enable the operations of connected systems. Which connectors should be used to connect these sensors?

Analog sensors capture important information about the operations of electronic systems and the world around them. In smart factories, connected homes and offices, agriculture operations, rail networks, flight operations, and transportation infrastructure, analog sensors collect environmental data such as pressure, sound, temperature, humidity, and light intensity to monitor activity, manage resources, and control operations. This information can directly drive system responses and activities that help predict maintenance, accomplish repairs, track the activities and productivity of equipment, and enable the operation of complex electronic systems. The information analog sensors collect can trigger immediate actions or can be digitized for further analysis.

Data moves from the sensor, through a network of cables and connectors, and finally to a processing unit. Simple systems may require one or a small number of analog sensing channels, while others may involve bringing many channels into a single port.

While there are often advantages to digitizing analog signals within the sensor — such as offloading analog-to-digital conversion workloads from the host system — the signals from analog sensors often need to be gathered into the process controller to be converted and analyzed. This can be influenced by factors such as sensor cost or power requirement, the number of sensing channels needed, or the number of analog inputs available at the host. A wide variety of standardized connectors are suitable for handling analog sensor signals, and options such as sealing, shielding, and locking can be specified to satisfy diverse application requirements.

Connector selection

Directly wiring analog sensors may appear to be an easy solution, particularly if the number of channels is small. However, hard-wired connections can slow down system assembly, be vulnerable to miswiring errors, and can complicate maintenance in the field. The sensor may be supplied with short leads, or pigtails, already attached, which can be soldered to bullet-type or similar connectors such as 6 mm spade connectors. However, if more than a small number of channels is needed, the wiring process can be laborious and error-prone, and connections can be unreliable.

Circular connectors

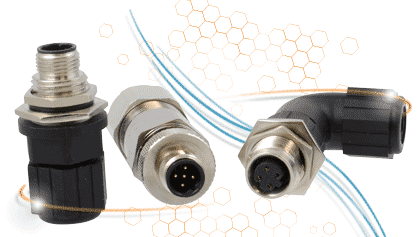

Industrial connector systems are an option that can deliver a multitude of benefits. These include circular locking connectors in standardized sizes, such as imperial 7/8” and M-type metric connectors. M8 and M12 mating interfaces are designed for 8 mm or 12 mm screw locks.

M12 circular connectors, such as these Amphenol M12s, are available from Avnet in a wide variety of configurations for use in diverse applications and environments.

M-type connectors are standardized according to IEC 61076-2, which encompasses both screw-locking and push-pull types. Standardization has encouraged the widespread adoption of these connectors in industrial control systems. Large-size M23 circular connectors are also available and can accommodate larger numbers of analog channels. On the other hand, smaller M5 circular connectors, typically containing two, three, or four contacts, can be used in applications where a small number of channels is required or where space calls for a small connector size. Some manufacturers offer connector series designed for specific applications such as the food industry, which requires special resilience to high-pressure washdown and cleaning chemicals, or railways, which are subject to continuous shocks and vibrations as well as weather conditions.

Note that circular connectors can be used for various applications including connecting signals, power, and fieldbus data lines. Hence, different codings are available to guard against mismating when different types are used in the same system. The IEC 61076-2 M8/M12 specifications specify different codings for signal transmission, power connections, and Ethernet or fieldbus data connections. The codings define the relative positions of pins and mating lugs and help prevent connector-mating errors.

As well as M-type circular connectors, coaxial types can be worth considering. RCA audio connectors and ¼” and 3.5 mm plug-type connectors, for example, are well-established and familiar standards. These can offer a reliable and cost-effective means of connecting analog signals, particularly with mono or stereo audio channels. Similarly, BNC connectors are easy to procure and are widely used in the audio/video industry as well as in electrical test and measurement equipment.

Rectangular connectors

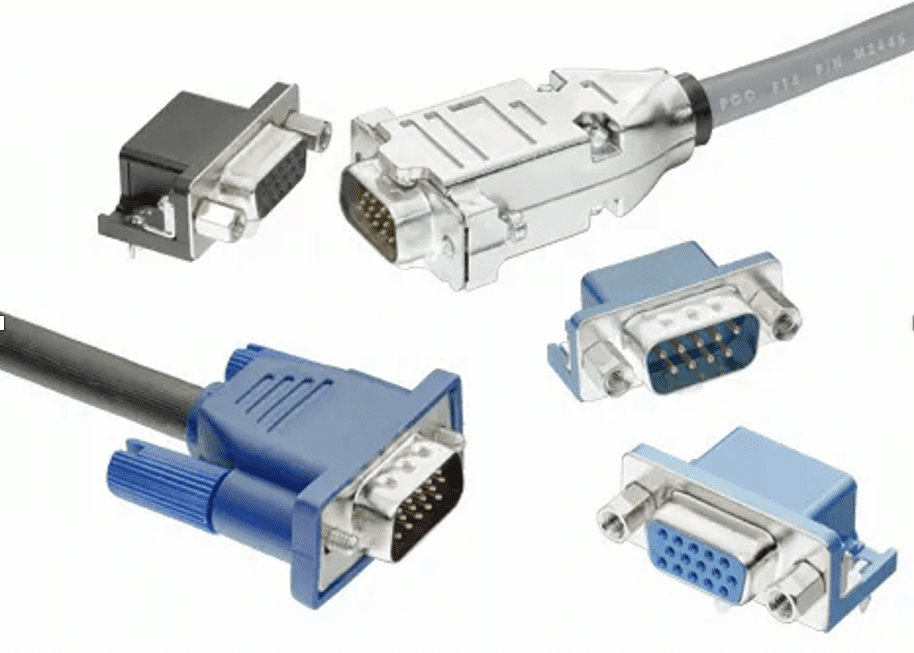

Rectangular sub-miniature D-type connectors (D-subs) are an economical and ubiquitous connector type frequently used in industrial and laboratory equipment. Available in cable-to-panel, surface mount (SMT), through-hole cable-to-board (vertical and 90°), and cable-to-cable versions, D-sub connectors cover contact densities ranging from as few as nine pins to over 100. The D-shaped interface prevents mismating and jackscrews. Squeeze-to-release latches prevent unwanted disconnection even in severe conditions such as those that might be encountered in harsh environment applications on trains or aircraft. Optional features include metal backshells that provide interference shielding.

D-sub connectors, such as these by TE Connectivity, available from Avnet, are available in various configurations, with or without shielding.

Mechanical Integrity

Ensuring that connections are reliable at all times is a must. Numerous hazards can threaten the integrity of the connections, including shock and vibration, corrosion, and human interference.

The locking ring on M-type and circular connectors, for example, is easy to use and secure when finger-tight to prevent the two connector halves from separating. This provides effective protection against unmating due to high shock or vibrational loads and also discourages inadvertent disconnection by unqualified or unauthorized individuals.

BNC connectors feature a bayonet connection for security, while RCA, ¼-inch, and 3.5 mm plugs engage with a retaining spring in the socket.

Electrical Attributes

Analog signaling standards commonly used by sensors for industrial applications include 0-10V, 0-5V, 1-5V, 2-10V, and 4-20mA. While these different approaches have various electrical advantages and disadvantages – such as easy detection of voltage signals, and the opportunity to power the sensor through the same two wires used for 4-20mA signaling – they have minimal impact on connector selection. However, a low ohmic contact resistance when the connector is mated helps preserve the integrity of current and voltage signals. It’s worth noting that connector systems are sometimes conceived to handle power as well as digital signals together in a single hybrid sensor, which can help simplify cabling and enhance the overall appearance.

Environmental hazards

M8 and M12 circular connectors are designed for industrial applications and incorporate sealing with IP ratings up to IP67 and IP69K, which prevents ingress when immersed in water. This allows use in outdoor environments that may present various hazards ranging from occasional splashes to heavy rain or flooding. While sealing protects against the ingress of moisture and other contaminants such as dust that could interfere with electrical connections, connector systems offered by major brands often contain gold-plated pins that maintain their condition and low-ohmic contact resistance even in corrosive environments.

Also, equipment designers can choose between plastic case or shell materials, which are economical and tough, or metal that provides advantages such as crush resistance, thermal protection, and inherent shielding.

Connector systems

Specifying a single connector system throughout a cabinet, product series, or site-wide installation offers several advantages. One is that the system will typically offer configurations to suit different wiring needs. These include connectors for inline cable mounting, panel mounting, wire-to-board connections, and others such as straight or right-angled orientations. Choosing connectors from the same portfolio can give a high-quality, ordered appearance to the wiring.

Connectors from the same series may be available with special features, such as 360° shielding that maintains continuity across the two parts of the connector when mated. Other valuable attributes that can influence selection include the prospects for assembling the connectors easily in the field, ideally with no need for special tooling. Using one system makes repairs and upgrades more streamlined.

Choosing a preferred connector system can also simplify procurement and inventory management and allow economies of scale. Moreover, suppliers can often provide off-the-shelf or custom cables, pre-assembled with the required connectors, tested, and ready for use. Product longevity should always be considered to ensure replacement parts will be available for future equipment maintenance and repairs.

Industrial connectors such as circular, D-types, and coaxial connectors are good choices to connect analog sensors. These connectors can handle typical signal amplitudes and speeds relatively easily. To select the right connector for a given application, designers need to consider factors such as installation and repair, environmental hazards, and disconnection risks. However, high-quality connector systems from leading manufacturers offer robust features to overcome such challenges.

Visit Avnet to learn more about sensors and connector products to accomplish your connected design goals.

Like this article? Check out our other Rectangular Connectors and M12 articles, our Transportation Market Page, and our 2023 and 2022 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.