Selecting the Correct Crimp Tool

Crimp tools are used to produce a reliable, long-lasting joint between the connector and cable, an essential termination process for optimum connector performance. Here’s how to choose the right one for your application.

Selecting the correct shape and size crimp tool is essential for a reliable termination.

When a crimp tool is used to terminate a cable with a connector, two crimps take place at the same time. One is the electrical connection between the conductor and terminal. The other is the insulation crimp. Crimping the insulation provides strain relief against vibration and tension.

Selecting the right size tool for the job is extremely important. Crimp tools are made to crimp to either imperial or metric sizes. While it can be tempting to try to make do with a crimp tool that is not the actual size required, this is not advisable for a number of reasons. Using a crimp tool with a crimp size that is too large will result in a loose and unsecure crimp, with the crimp allowing too much movement of the cable. Over time flexing of the cable will lead to damage to the connection and ultimately loss of signal. When crimping, it is important not to overstress the integrity of a joint. Crimping too tightly with too small a crimp size can be highly detrimental, cutting into the cable and damaging the connector.

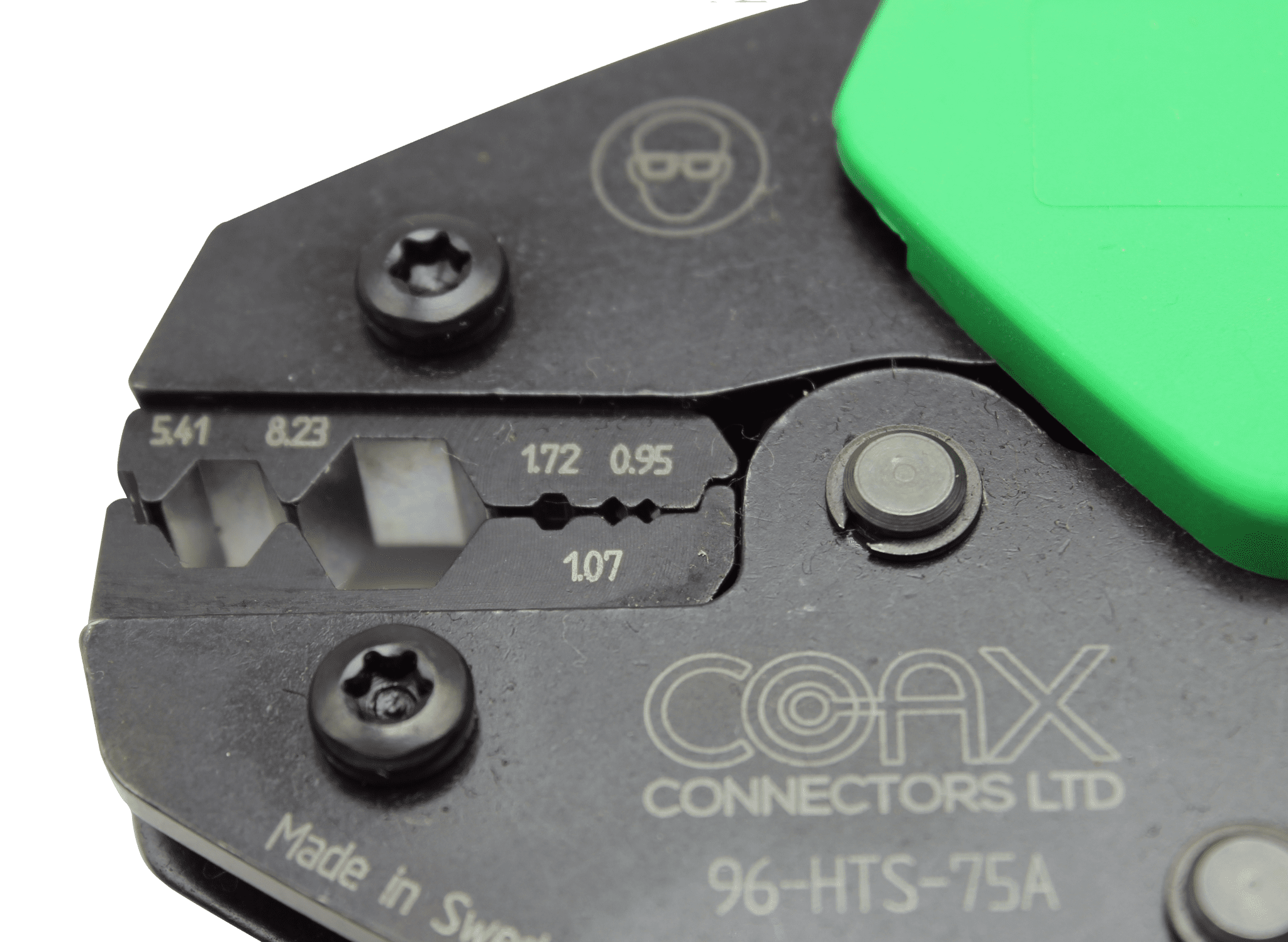

Using the correct crimp tool shape, whether that be hex, indent, or square, is also essential. Indent and square crimps tend to be used for center contacts, with hex crimps being used for the outer tube. However, hex crimps are used for center contacts for cables with a larger diameter.

Crimp tool for hex and square crimps, marked with crimp sizes.

A sometimes-overlooked issue relating to crimping is the use of the right materials to avoid fracturing or damage. If the crimp tube is too hard it can cut into the cable. Annealing connector parts such as crimp tubes and crimp contacts during manufacturing alters the microstructure of the materials they are produced from, reducing hardness, increasing ductility, and helping to eliminate internal stresses. High-quality connectors tend to be manufactured with annealed or zone annealed crimp tubes and crimp contacts, which, being softer, are less likely to cause damage during the crimping process and are not so prone to fracturing.

Use of high-quality connectors with annealed crimp tubes and contacts reduces the likelihood of fracturing when crimping.

Reputable connector manufacturers will not only take materials into consideration in development of their products but will also be able to provide details of the precise crimp sizes and shapes for their connectors and recommend a suitable crimp tool for terminating them correctly.

Visit COAX Connectors Ltd. to learn more.

Find this article and more expert insights on connectivity components in our new eBook Connectivity Components: Everything but Complete Connectors, available for free download now.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

Like this article? Check out our other Cable articles, and our Wire/Cable Assemblies Market Pages, and our 2021 Article Archives.

- Selecting the Correct Crimp Tool - October 5, 2021