Outgassing Components Pose Risk to Sensitive Electronics

Careful materials selection and specialty outgassing processes help reduce volatile gases present in connected systems.

On Earth, our concerns about outgassing center on the impact of particulate chemicals on human health. The synthetic materials in petroleum- and chemical-based products such as plastics, furniture, carpet, paint, and adhesives release volatile organic compounds (VOCs) and other airborne chemicals. Referred to as outgassing or off-gassing, the release of VOCs is typically highest in newly produced or installed products, but other VOCs may be released as materials age or are subjected to specific light conditions, temperatures, radiation, or cleaning processes. Exposure to some VOCs is associated with cancer, autoimmune disorders, and other health problems. So why is outgassing a concern in outer space or indoor environments where there are few or no humans to be exposed to the risks? Because electronics are also adversely affected by outgassing.

In closed indoor environments with a significant volume of electronics, such as data centers, indoor air pollution from outgassing polymers, adhesives, and epoxies can be high. These VOCs can lead to corrosion or buildup of contaminants on components or instruments, reducing performance and reliability. They can also impact instruments used in scientific research and reduce sterility in medical applications. Mirrors, lenses, and sensors in particular can become clouded by VOC condensation and buildup. Connectors are impacted when VOCs collect on connector faces or contacts, degrading the quality of the signal. Specifying sealed connectors that are IP-rated to protect against gases can be helpful. In closed conditions, VOCs can also be mitigated with the use of air filtration systems.

In space, however, outgassing cannot be controlled or protected against. In the high-vacuum environment of space, plastics used in electronics and other materials expand and release gases, which can then collect and pose significant concern to high-reliability electronic components used in equipment such as satellites and spacecraft. The atmospheric conditions of low-Earth and outer orbit can accelerate the emission of airborne particulates as the polymers react to changing temperatures or radiation conditions.

Cable assemblies used in space applications must be low outgassing. Times Microwave Systems selects non-polymeric materials and preconditions them to ensure that outgassing is minimized in space flight.

“As the satellite is launched into atmosphere, the materials inside will, by definition, relax and release gasses,” said Maria Calia, senior program manager, Times Microwave Systems. “In the case of a satellite or equipment used on space missions, you typically have several instruments and optic systems, like lenses. If you release high amounts of condensable gases through the outgassing of electronic components, they can obstruct the view of the optics, leading to a loss of critical instrumentation.”

NASA, the European Space Agency (ESA), American Society for Testing and Materials (ASTM), and other organizations have developed guidelines to limit outgassing by components used in space applications. “All plastics will outgas to a certain extent. Some more than others,” Calia said. “One of the most stringent standards used in the space industry is ASTM E595-15, which defines the test conditions necessary to measure the amount of outgassing a material will produce. The tests measure the amounts of gases that condense after a certain amount of time at a certain temperature. This standard also defines acceptable levels for gasses released within space applications, thus guiding the material selection for components. By complying with that standard, a supplier assures the customer that the materials will emit an amount of gas within the threshold that is allowed.”

When specifying a connector or any other component for a space application, the engineer needs to identify all materials. If a material is not defined as acceptable by NASA or other relevant guidelines, a component might have to be replaced by one made with a specific material, said Calia. “As RF applications reach higher frequencies, low loss is a key requirement of most interconnect components. Changing the design of a connector will impact how the frequency wave travels from the coaxial layers into the interface. As the engineer specifies materials for space applications, it is critical that all electrical design is also reviewed. Simulation tools like the CST software are used to review technical performance. These tools will provide engineers the information necessary to adjust the design until it meets not only the outgassing requirements, but the electrical performance as well.”

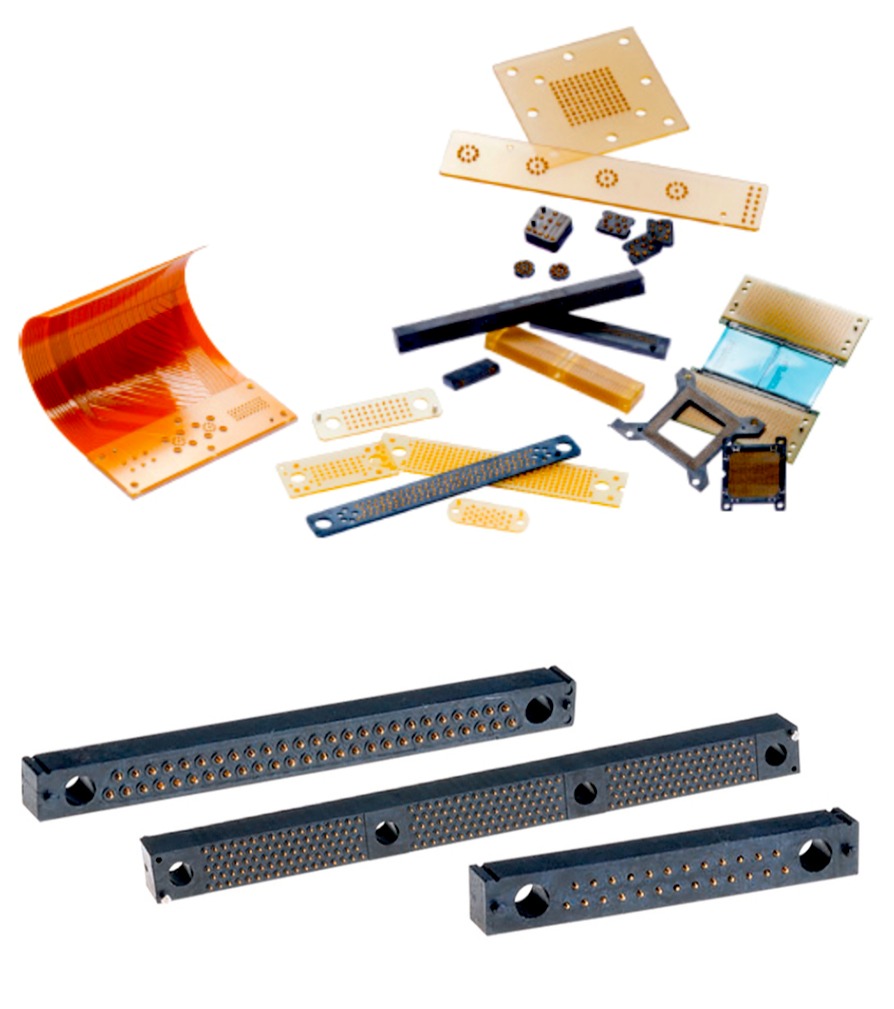

Cinch’s CIN::APSE line includes custom solderless, high-density stacking connectors and jumpers that are developed for space applications. They meet NASA outgassing levels in accordance with ASTM E595.

Brad Taras, product manager at Cinch Connectivity Solutions, said that every material in a component, from polymers to adhesives, inks, and epoxies, should be audited before specification. Components are then typically prepared for use by curing them in special outgassing ovens. This process exposes the polymers to specific temperatures for a pre-determined amount of time necessary to force the gases out of the component, usually when it is inside of a mold. “When a material outgasses, it releases tiny bubbles of gas, and that release can change the mechanical structure of the component,” said Taras. Cinch uses the oven for its Dura-Con micro-D subminiature and CIN::APSE custom stacking connector lines. “Curing the component helps ensure that it retains its integrity in the actual operating environment.”

PEI-Genesis extracts VOCs from components specified for space applications in a specialty vacuum oven. After this process, the components are tested to make sure they meet applicable standards.Companies that specialize in components for use in space and other high-reliability environments may have in-house outgassing vacuum ovens. Others may outsource outgassing processes to specialty labs that can bake and test new components to specific extremes and provide detailed performance measurements. When an outgassed or low-outgassing component is specified, that assurance carries through to the delivery of the product to the customer.

“Once all assemblies are properly designed, manufactured, assembled, and tested, they need to be transported from the cleanroom to the end user,” said Rodriguez. “These assemblies are often packaged in specially designed electrostatic discharge bags. These bags include a humidity indicator. Since the production process is controlled, any changes in humidity introduced during transport can be measured. This level of variable traceability allows for mitigation steps such as baking the interconnect prior, or after, its assembly into the system.”

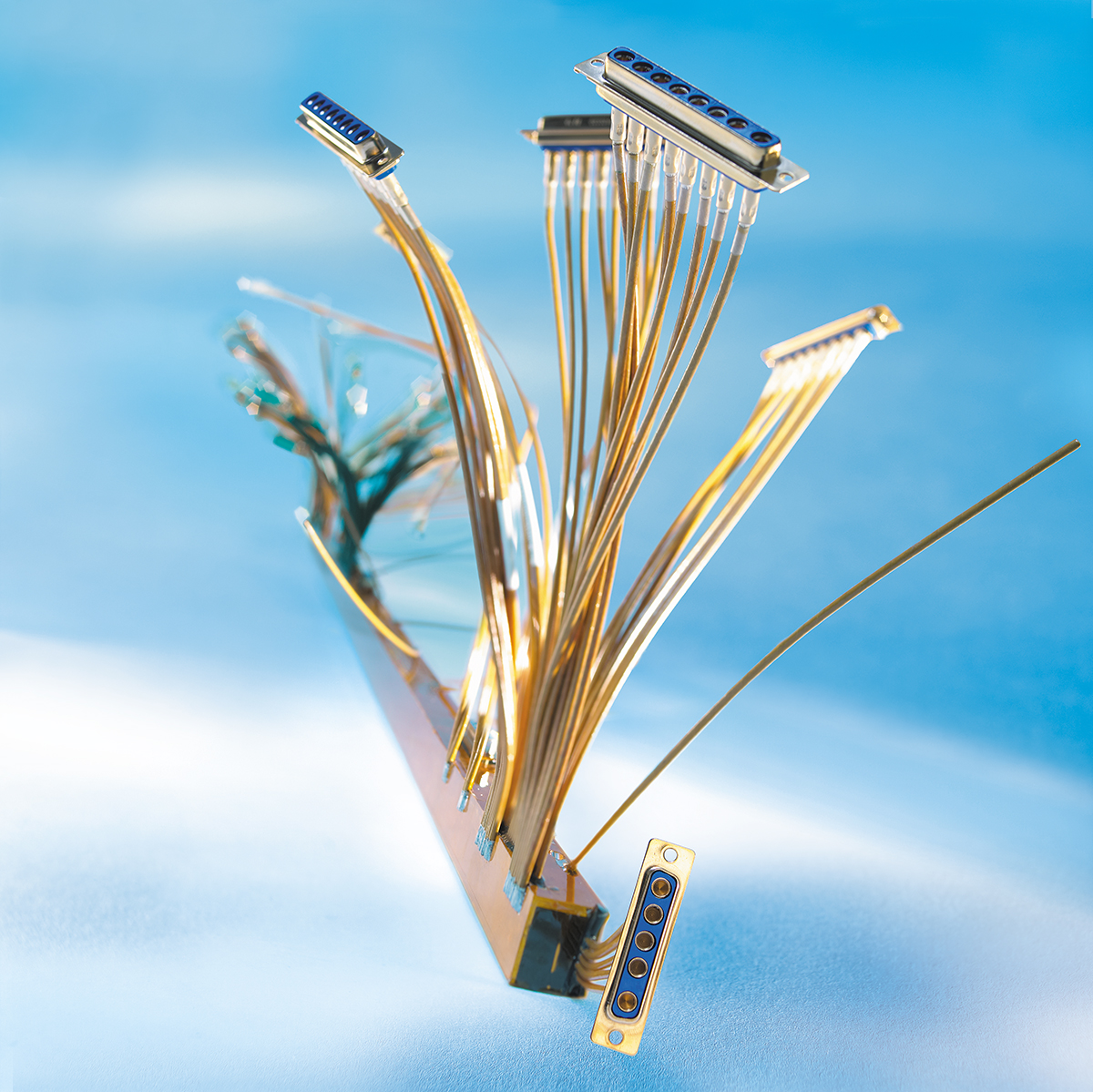

Axon’ Cable is equipped with a thermal chamber that helps outgas its harnesses and ensure performance in the end application.

Axon’ Cable designs and manufactures ESA and space-grade wires and cables, miniature connectors, and cable assemblies and harnesses for a large number of space applications (ISS, planetary missions, satellites etc). “We are very well-versed in the constraints of the space market, and take out-gassing into account from the very beginning of the design of our tailor-made interconnect links,” said Sandrine Hermant, marketing project manager at Axon’ Cable. “We select materials such as thermoplastics, polyimide, or PTFE with low outgassing properties for our wires and cables. The materials of the inserts and seals used in our connectors are selected with the same concern. Materials involved in the manufacturing process are also chosen to limit outgassing; for example, the potting process used to manufacture bus bars.”

Axon’ Cable’s bus bars are used in power distribution in telecommunication satellites and land-based weapon systems. Materials for these interconnects are carefully selected and prepared to minimize outgassing.

Hermant says the company closely monitors materials for obsolescence, and conducts reviews to validate new materials, as products and guidelines change frequently.

Electronics face extreme and challenging conditions in space and other high-reliability operating environments. But there are many steps that suppliers can take to provide components that are ready to face the invisible enemy, VOCs.

Like this article? Check out our other Connector Basics, and Harsh Environment articles, our Military and Aerospace Market Page, and our 2021 and 2020 Article Archives.

- Meet the Connector: DIN Standard Connectors - April 16, 2024

- Software-Driven Radio Reinvigorates Old Technology - April 9, 2024

- What is a Busbar? - April 2, 2024