Hidden Connectors

Sleek designs, subtle colors, and hidden locations help connectors blend in when applications need to look good or not be seen at all.

A visible connector is easier to mate than a hidden connector. Color coding, accessible positioning, and LEDs help operators make the correct selection in environments where multiple cables and ports are present. However, miniaturization, positioning, and color choices serve aesthetic and safety goals for soldier-worn or tactical equipment that needs to blend into battlefield environments. In high-design environments or body-worn medical devices, discretion is also important.

Coloration is one way a connector can be hidden. U.S. military specifications dictate specific colors, including Green 383 Camouflage, Brown 383 Camouflage, and Black Camouflage, to be used in clothing and equipment. Electronic packaging should adhere to these specifications as much as possible and interconnects can support the overall camo goal by using specified colors in cable jacketing, overmolding, and plating, and by avoiding shiny finishes that can catch and reflect light.

“Many designers are trying to get away from the color black in certain military applications. Black absorbs light and during the day an enemy can scan a complex landscape and look for spots of ‘missing’ light,” said Omnetics’ Connector Corporation’s Director of Marketing & Market Development Scott Unzen. “A better choice would be olive drab cadmium. Cadmium has environmental concerns, but it is still the gold standard. It offers great connectivity, resists salt spray and corrosion, and olive drab plating matches most military equipment.”

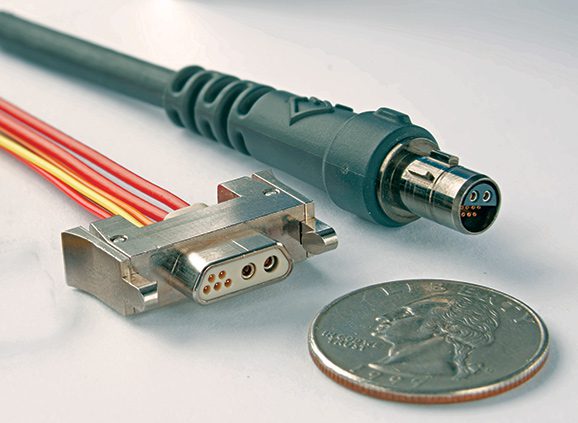

Omnetics’ flat design connector system, utilized by Black Diamond for military electronics, uses pogo pin technology for reliability and easy cleaning in the field. Miniaturization is another important element in designing lightweight, small equipment that can be routed under clothing.

Amphenol Industrial’s MIL-DTL-5015 in Solder Olive Drab, available from Allied Electronics, is designed to blend into military applications.

Amphenol RF introduced a black zinc‐cobalt plating option for a variety of radio frequency connectors and coaxial adapters. This alternate plating is RoHS and REACH compliant and designed to be non‐reflective for covert applications such as military communication equipment. Black plating is an excellent choice for applications such as precision positioning systems, radar receivers, surveillance equipment, and drones used to avoid enemy detection.

Amphenol RF’s black-plated connectors and adapters are available in waterproof IP67 rated configurations which allows them to maintain excellent RF performance even during temporary submergence. Alternate plating allows engineers to use existing RF interconnect in new and different applications to meet more specific design requirements.

Discrete medical devices

Minimizing connection points by specifying hybrid connectors that combine multiple functions, such as transmitting power, signal, fluidic, or gases, helps streamline the appearance of medical equipment and simplifies the user experience. For wearable medical electronics, hidden connectors contribute to discretion and comfort. Many patient wearables can be hidden under clothing, but for those that can’t, such as hearing devices, strategic design choices help create a more pleasing appearance. Omnetics offers some of its miniaturized interconnects in colors such as taupe and black to blend better with different skin tones. The most popular color for medical interconnects is white, says Unzen, both for cleanability and compatibility with the dominant color scheme of medical environments. In these situations, white helps camouflage equipment and creates a clean, calm look.

Consumer design

Invisible connectors serve the design of consumer applications too. In public spaces, discreet connectors protect electronic systems from potential interference. Some humans can’t resist tampering with sockets or wires, and building electronics, street furniture, antenna installations, and lighting must be designed to minimize access and obscure the appearance of interconnects whenever possible to protect the system yet enable access for maintenance.

The main consideration with consumer goods, however, is aesthetics. A sleek product design would be marred by obtrusive connections, so colors that match the product or form factors that inset connectors a few millimeters into a product can help hide unsightly battery connectors or power supplies. White or clear plastic housing and cable jacketing helps meet this goal.

Wieland’s gesis products, available from Allied Electronics & Automation, are designed to provide aesthetically pleasing connections for lighting installations, such as those used in display cabinets, where nothing about the wiring should distract the eye.

Apple, always a master of aesthetics, even registered a trademark in 2016 for a virtually invisible connector port on the backside of its iPhone. The iPhone’s connector would be able to penetrate this seemingly invisible port when needed and when the connector is removed, the seam, using a self-healing material, would close and appear invisible once again. We haven’t seen it appear on the market yet, though. Some practical considerations come to mind — cost, cleanability, and obstruction by phone cases come to mind. Wireless charging seems to be a better solution. In that case, the interconnects are completely invisible — because they are hidden inside the device.

Like this article? Check out our other articles covering Wearables and Miniaturization, our Mil/Aero Industry articles, and 2022 and 2023 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Meet the Connector: DIN Standard Connectors - April 16, 2024

- Software-Driven Radio Reinvigorates Old Technology - April 9, 2024

- What is a Busbar? - April 2, 2024