Fast, Small and Lean: System Cabling Pays Off

Panel builders can reduce wiring time, achieve a denser, leaner cabinet, and cut costs by moving to a system cabling solution.

By Michael Hardman, Product Marketing Specialist, Phoenix Contact USA

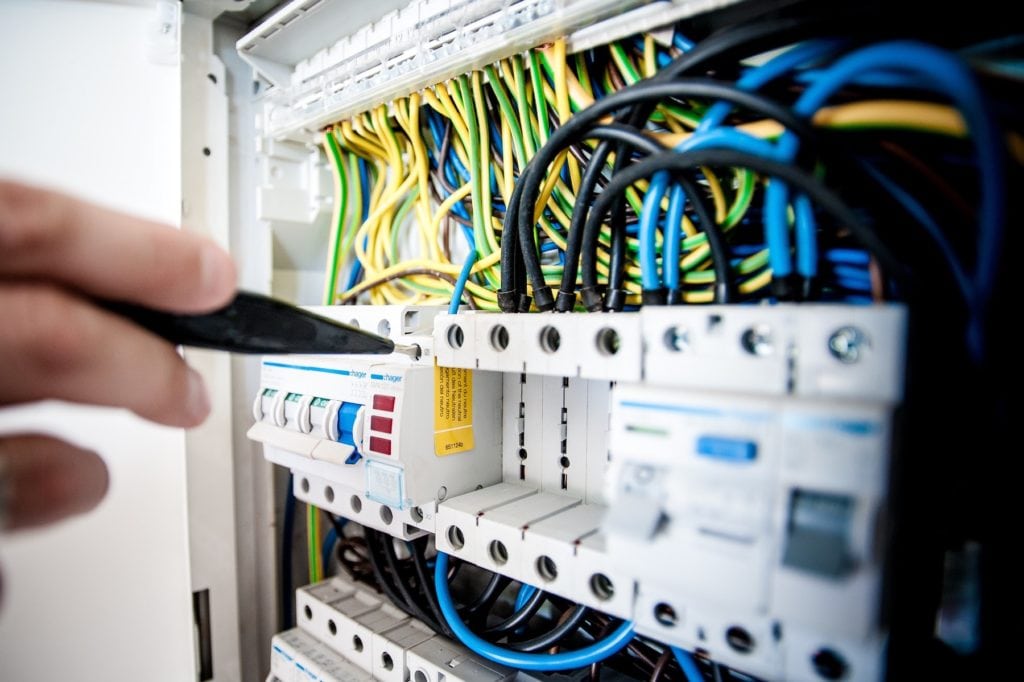

In today’s industrial controls marketplace, customers are insisting on control cabinets that are less cluttered and take up less real estate than ever before. They also require ever-speedier lead times for the production and shipment of these smaller, cleaner cabinets. These two requirements are traditionally antithetical to each other. Laying out panel wiring in tighter spaces is typically much more difficult and time consuming for panel technicians. By moving to a system cabling solution, however, panel builders can easily achieve both faster wiring times and denser, leaner cabinets.

Here’s how a system cabling solution for control wiring typically works. Traditional control panel wiring for a programmable logic controller (PLC) or distributed control system (DCS) involves landing the field signals onto rows of individual terminal blocks and relays. These signals are then connected to the controller via point-to-point connections with individual conductors, all of which must be individually cut to length, stripped, ferruled, and terminated at the I/O card.

System cabling solutions replace this laborious process by implementing a three-piece solution set. First, high-density field termination assemblies (FTAs) are used in place of the individual terminal blocks and relays. These FTAs have screw or push-in terminals on the field side to accept the field wires just as before, but the control side of the FTA has a high-density connector, such as a ribbon or D-Sub connector, in place of the individual terminals. The second part of these three-piece solutions is a faceplate adapter for the I/O card. These adapters have one or more high-density connectors on one side and are installed in place of the individual terminal blocks that come with the I/O card. The third and final part of system cabling solutions is the jacketed cable that connects the FTAs to the I/O card adapters.

A system cabling solution is up to 15 times faster than traditional control wiring.

Plug-and-play system cabling solutions eliminate the tedious and time-consuming effort of traditional point-to-point control wiring. The labor savings of this approach is significant. In fact, it’s at least 15 times faster than traditional control wiring. This time study video illustrates the process using a 16-channel I/O card as an example, and the time savings would be even more pronounced on a 32-channel I/O card.

This incredible increase in wiring ease and the reduction in wiring time does not come freely, though. As one could imagine, system cabling solutions have a higher upfront bill of materials (BOM) cost than traditional wiring solutions. Terminal blocks are reasonably inexpensive and most shops consider spools of conductors to be amongst essential overhead costs. But while system cabling solutions have higher BOM costs, the extreme ease and speed of wiring they provide allows panel builders to vastly increase their throughput, and increasing the number of panels sold each week, even at a slightly lower per-panel profit margin, will still substantially increase the bottom line. This video illustrates a costing scenario.

System cabling solutions also allow panel builders to save money in other, more explicit ways. For example, when wiring a controller traditionally, it is often exceedingly difficult to utilize an I/O card with any more than 16 channels. When moving up to 32-channel cards, the spacing between terminals on the I/O card is so tight that installers would need incredibly small, dexterous hands to be able to terminate individual wires accurately. System cabling solutions remove this hindrance, allowing panel builders to simply plug in a high-density cable, and also allow them to utilize fewer, but higher-density, I/O cards to save real dollars on BOM costs, especially if the build can use a single 32-channel card instead of two 16-channel cards.

A system cabling system consists of an I/O card adapter, high-density cable, and field termination assembly.

Additionally, system cabling solutions can encourage the expanded use of low-voltage I/O in cabinets. If a few high-voltage field devices are required, system cabling enables pluggable connections to interposing relays that step down high-voltage field signals to low-voltage I/O. Switching to low-voltage I/O in place of more expensive specialty high-voltage I/O cards is another way to save BOM costs, and creates safer cabinets for technicians to service. System cabling relay solutions also allow panel builders to utilize less expensive standard output I/O cards instead of expensive specialty output cards with built-in relays. If and when a relay contact fails in these systems, it is both significantly easier and less expensive to replace a single pluggable relay than to replace an entire specialty relay output I/O card.

No longer are the two major demands of industrial control cabinets — a smaller, denser cabinet and a quicker production and delivery timeline — antithetical. The system cabling approach to cabinet control wiring finally allows panel builders to have it both ways. By utilizing more standardized, higher-density I/O cards in combination with a pluggable and easy-to-wire system cabling solution, panel builders can achieve sleeker, smaller, higher-density control cabinets with greater ease in a shorter amount of time.

Learn more at Phoenix Contact.

Interested in a specific market? Click a market below for current articles and news.

Automotive, Consumer, Industrial, Medical, Mil/Aero, Datacom/Telecom, and Transportation