E-Mobility Expands in Recreational Vehicles

Electric drivetrains are moving into more off-road categories of recreational vehicles. Snowmobiles, personal watercraft, ATVs, and other powersport vehicles are actively adopting connectivity solutions used in motorcycle, e-bike, and automotive designs.

Although the development of electric drivetrains for cars, trucks, and mass transit is well underway, two-stroke-engine powersport vehicles such as snowmobiles, off-road vehicles, and personal watercraft (PWC) still largely depend on gas. But that is changing. Established companies and specialty startups are developing new battery-powered electric powersport equipment that offers the high speeds and performance that riders require, along with much quieter operation and a cleaner energy footprint, which is critically important since a single two-stroke engine emits as much pollution as 30 to 50 four-stroke-engine automobiles. Powersport OEMs are meeting the challenge of providing a greener product that offers the same or better performance than gas-powered models at a competitive price.

Canada-based Taiga Motors has developed the first commercially available all-electric snowmobile. Taiga set out to create the “Tesla of snowmobiles” — a high-performance, all-electric machine that provides a long range and high-tech safety and comfort features. The company also plans to introduce electric PWCs. Taiga snowmobiles use a lithium ion battery pack and integrate full GPS, LTE, Wi-Fi, and Bluetooth connectivity features for high-definition displays that show maps, custom terrain profiles, and range data. The onboard systems also interface with a phone app for advance maintenance and diagnostic information. The Taiga’s fueling, charging, and operational technologies are unified in a streamlined cabling architecture to save weight and reduce costs. The company has also developed some proprietary electronic components, under the design philosophy that custom parts give them more control than off-the-shelf components. These high-tech sleds can reach top speeds of 110km/h (68mph) to 160km/h (100mph) and provide a range of 131km (~81 miles) at speeds of 60km/h (37mph) on a single charge.

One challenge in designing electric-powered equipment for snowmobiles and other off-road recreational vehicles that can operate in extreme cold is battery drain. The Taiga TS3 platform’s lithium-ion battery pack is protected by an advanced thermal management system that intuitively heats or cools the battery as needed to reach optimal operating temperatures, limiting battery drain to just 1–5% in temperatures down to -40°C.

In 2020, top snowmobile brand Polaris announced a technology partnership with Zero Motorcycles that will bring its first electric snowmobiles and all-terrain vehicles (ATVs) to market by the end of 2021 and add electric models to each of its product lines by 2025. Zero has been making electric motorcycles since 2006, which allows Polaris to rapidly implement EV powertrain technology, hardware, and software. “We believe this transformative partnership will enable us to leapfrog technological hurdles around range and cost while providing a tremendous speed-to-market advantage as an instant offense,” said Scott Wine, chairman and CEO of Polaris. Zero powertrains provide electrified propulsion through a modular, high-torque motor and compact lithium ion battery.

A Zero DS motorcycle can travel over 200,000 miles with the batteries retaining 80% of their original maximum capacity. Polaris will now adopt this technology for its recreational vehicles.

Electric motorcycle development is a few years ahead of other small recreational vehicles, with all-electric models available now from Zero, Harley-Davidson, Arc Vector, Vespa, Zero FSX, and several other brands. A number of connector suppliers offer connectivity products for the e-bicycle and electric motorcycle markers, and these components transfer well to other small recreational vehicles. A key quality is ruggedization, which is needed to endure the shock and vibration that is part of off-road ride experiences. Since powersport vehicles are operated in all weather conditions and climates, charging connections and other electronic interfaces must also be rated for a wide range of temperatures. Waterproofing is another key quality: Connectors must be sealed against moisture and, for personal watercraft, against salt spray. At the same time, the connectors, cables, sensors, and antennas used in these smaller machines must be scaled down and lightweight.

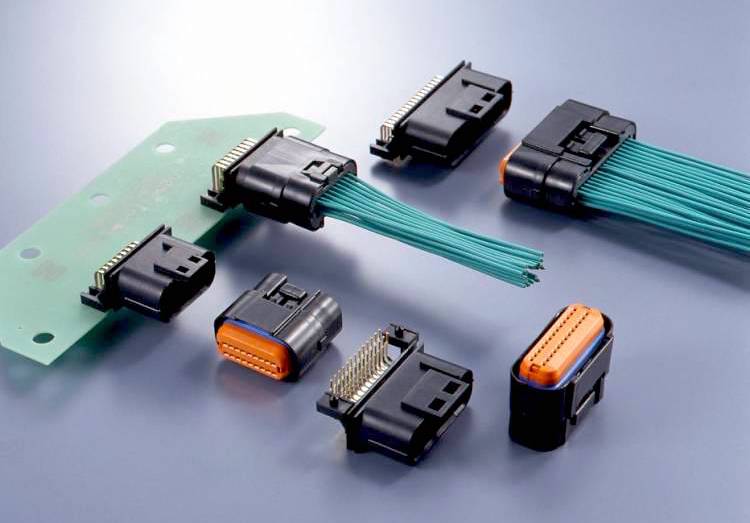

JAE’s MX23A series of compact board-to-cable contact connectors can be used for wide range equipment since they are waterproof, with a sealed mating area and grommets in the wire crimping area. “They are used as the main powertrain connectors and are ideal for motorcycle applications, given their low-profile and compact design,” said Steine Hermann, product marketing specialist at JAE. “In addition, the reversible mount options allow these connectors to be adopted by a wider range of design structures.”

JAE’s MX23A connectors offer compact, waterproof, and high-reliability solutions ideally suited for automotive applications, as well as smaller recreational vehicles including motorcycles and ATVs.

ITT Cannon’s Trident Connector System is a versatile range of connectors that support power sports applications. These circular and rectangular connector products are specifically designed for harsh environment applications. They come with membrane wire seals that meet the requirements for IP67 and do not require blanking plugs for unused cavities. They accept various combinations of signal (13A) and power (30A) contacts. The receptacle connectors feature stainless steel bayonet pins integrally molded into the bodies. This line has the ruggedization and reliability features needed for rail, heavy equipment, and other large equipment, but they also have the versatility to serve small machinery.

Cables used in electric off-road vehicle applications must also meet high standards for performance and reliability. BizLink emphasizes compact, digital solutions that meet industry standards and enable easy integration but provide a lot of room for innovation in a rapidly evolving market. “The raw wires that we produce for the harnesses of off-road vehicles meet global standards such as SAE J1127, SAE J1128, SAE J1939, SAE J156, UL 1581, and RoHS 2.0. We usually provide customized manufacturing service for our customers, and our production quality can fulfill the standards of USCAR 21 and IPC 620,” said H.H. Yeh, senior program manager at BizLink, a company that provides high-voltage, high-current wire harnesses for the recreational vehicle market. In e-mobility applications, cable and wire products must do more than just deliver power and signal. “Electric drivetrains require high-voltage cables and harnesses with shielding to prevent interference. At the same time, the harnesses have to be compact and highly integrated for more electronic modules in order to reduce the weight of drivetrains.”

Electric recreational vehicles charge using the same infrastructure and equipment as electric cars. Taiga’s lithium ion battery can fully recharge in as little as 20 minutes using Level 3 charging technology. Levels 1 and 2 provide a charge within two or 10 hours, respectively, using a 120VAC household outlet. The charging system connects with a standard SAE J1772 EV plug; in the EU, an adaptor for type 2 IEC charging is needed. The Taiga has an onboard charger and is connected to charging equipment using a simple lightweight adapter cable. Charging system connections for powersport vehicles must be easy for inexperienced users to operate, especially since they may have cold, wet, or gloved hands.

Snowmobiles, motorcycles, all-terrain vehicles, and other off-road recreational vehicles use the SAE J1772 charging connector developed for electric automobiles to enable refueling at the same charging stations. Phoenix Contact, which manufactures the CHARX charging cable assemblies pictured left, and ITT Cannon, which manufactures the J2CE charging connector pictured right, are among the companies that offer standards-compliant connectivity products for electric vehicle charging.

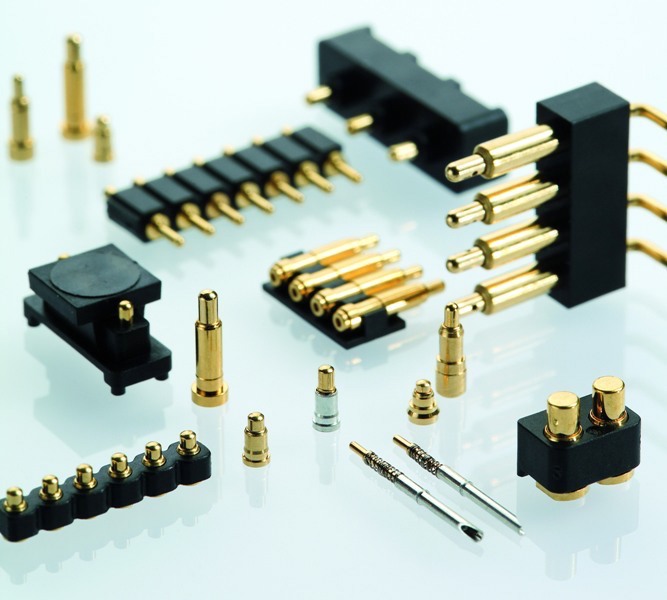

Inside the machine, the connections between the motor and battery must also be secure. Preci-Dip offers a line of spring-loaded contacts with clip technology to facilitate more reliable connections between motors and batteries in small electric powersport vehicles, as well as critical board-to-board connections inside the vehicle. The integrated multi-finger elastic clips also establish an efficient connection in blind-mating situations, solving issues of misalignment and non-coplanar mating conditions. “The clip technology gives our spring-loaded contact a unique reliability and signal integrity,” said Clément Bidault, marketing engineer at Preci-Dip.

Preci-Dip’s spring-loaded clip connectors compensate for potential user issues, ensuring secure connections despite irregular positioning tolerances or a pivoting or rotating approach.

As off-road vehicles become more connected, they also require more sensor interconnects. TE Connectivity has worked extensively with designers of electric motorcycles, e-bikes, scooters, and Segways to advance electric technologies for these unique vehicles. The company offers AMP Superseal connectors for temperature, manifold, pressure, and oxygen (lambda) sensors. These rugged, environmentally sealed interconnects enable small vehicles to continuously evaluate operating conditions and system functions using sensors, and protect critical power and signal functions in the electric drivetrain.

TE Connectivity’s AMP Superseal connectors are used throughout electric off-road vehicles. Their ruggedization and small size make them versatile choices for small recreational vehicles.

Within the next few months, these new recreational vehicles will introduce the advantages of electric drivetrains to even more outdoors enthusiasts, and the category will continue to be refined. The SAE International Clean Snowmobile Challenge, an engineering design competition for undergraduate and graduate students, is one initiative that is driving innovation in the powersports category. Competitors reengineer an existing snowmobile to reduce emissions and noise. Their designs compete in a variety of events to demonstrate performance in emissions, noise, fuel economy/endurance, acceleration, handling, static display, cold start, and design. This annual competition ensures that efforts will continue to perfect electric drivetrains, even for the smallest powersport vehicles.

Like this article? Check out our other New Technology, Connected Vehicle, and EV/HEV articles, our Transportation Market Page, and our 2020 and 2019 Article Archives.

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024