The Connector World Embraces Antennas and Sensors

Acting in tandem with high-speed interconnects, antennas and sensors can collect and convey a world of data. They act as the eyes and ears of today’s connected world.

Everything is connected. But for once, we’re not talking about connectors. We’re taking a closer look at the passive technologies that enable the autonomous and interconnected functions of the Internet of Things (IoT), Industry 4.0, the rollout of 5G networks, smart cities, connected cars, and high-speed communications. In particular, antennas and sensors deserve recognition for their critical function as the eyes and ears of these systems. These electronic devices monitor and collect signals and data, and with the help of high-speed cable and connectors, transmit it to processing centers where a rapid-fire chain of decisions are made and functions are activated. In the case of automated vehicles and other critical systems, this information must be collected, processed, and acted upon instantaneously.

Many connector companies have made acquisitions or expanded their R&D functions to become full-scale interconnect solutions companies that can provide connectors, cables, sensors, and antennas. Their goal is to better serve designers by offering connectivity products that play well together and anticipate the continuous scaling of technologies. Connector companies and distributors are expanding their offerings of these devices and in many cases, companies are working closely with the engineering community to develop new devices, evaluate their potential performance in a design, and even help determine the optimal placement of antennas and sensors into a system.

Antennas

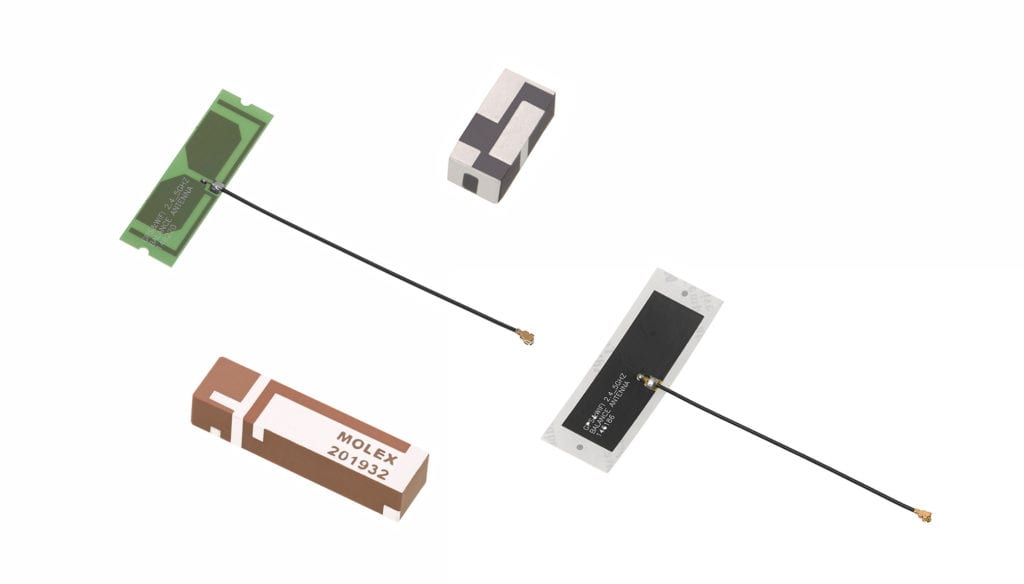

“Looking at the increasing numbers of wirelessly connected devices around us, the question is not if more antennas will be needed, but what kind,” said Wolf Martin Neugebauer, corporate distribution account manager, Molex. The company has been developing antenna capabilities since the 1990s, and in recent years has also added expertise through companies such as the Connected Vehicle Solutions division of Laird Limited, which Molex acquired in 2018. Arrow Electronics has been instrumental in bringing these antenna products to the engineering community.

Laird TM2M shark fin antenna

“We see device architecture evolving from embedding an antenna, to including multiple antennas as the electronics mature in the device lifecycle. Today, Molex antennas are being used in almost all markets in a variety of applications, from everyday consumer devices up to demanding automotive and industrial, or even highly sensitive medical applications. Essentially, most devices that have a microprocessor, now either have an antenna, or it can be expected that the device will incorporate antennas in a future version.”

Antennas in common use include traditional ground plane or Marconi-type antennas, loop antennas, patch or microstrip antennas, dipole antennas, and direction gain antennas (commonly known as dish antennas). They may operate alone or collectively, in groupings of multiple antenna configurations, such as multiple-input, multiple-output antennas (MIMOs).

Molex Combo Antennas

Neugebauer says that modern wireless products depend largely on internal antennas, which come with a micro coaxial cable leading to the respective plug. “These can be either embedded antennas, to solder on a PCB, or FPC, or cabled antennas, which can be fixed on the inside of a housing,” he says. Larger machines, heavy equipment, and vehicles use external antennas or a combination of both.

With so many new antenna and sensor products entering the marketplace, connector companies are offering a high degree of guidance to engineers. TTI Inc. has published the TTI Antenna Selection Guide, a reference guide that charts manufacturer-specific data concerning applications, physical types of antenna, and band applications. Newark’s Connector e-Guide helps designers determine what connectors would be compatible with sensor products.

AVX/Ethertronics’ Universal Broadband Embedded LTE/LPWA antenna

AVX/Ethertronics’ Universal Broadband Embedded LTE/LPWA antenna provides superior RF field containment and less interference or reaction with surrounding components, important in the automotive environment.

“It is always wise to start the design of a wireless device from the antenna selection. As obvious as this may seem, this is not always what really happens,” said Neugebauer. When the suitable antenna is identified, the product designers should follow the implementation recommendations in the application specs and build around the antenna. This will save them a great deal of time and resources when the time comes to validate the device’s performance. Validation is the next key word; as soon as the first prototypes are available, the performance of the device should be measured to ensure that it fulfills the application’s performance requirements. Lastly, when the device design is completed and the first mature products are manufactured, it is always a good idea to run one final test to ensure that the desired wireless performance is achieved.”

TE Connectivity’s ERFV RF coax connectors for 5G wireless applications

Sensing Data

In almost every autonomous or interconnected system, a host of sensors perform key functions, tracking, measuring, weighing, evaluating, and communicating various data. They can respond to changes in the environment, such as temperature, barometric pressure, moisture, and vibration. They are able to detect chemicals in the atmosphere or liquids. In a security system, they can detect motion and proximity. In medical technology, magnetic sensors can help monitor heart rate, blood pressure, temperature, and a host of other metrics. In industrial settings, sensors provide data and analytics that help keep production moving continuously. They are integrated into simple devices, such as pedometers and TV remote controls, as well as complex autonomous vehicles systems, where radar sensors, image sensors, and LiDAR sensors act in tandem to collect information about road conditions, obstacles, and other traffic.

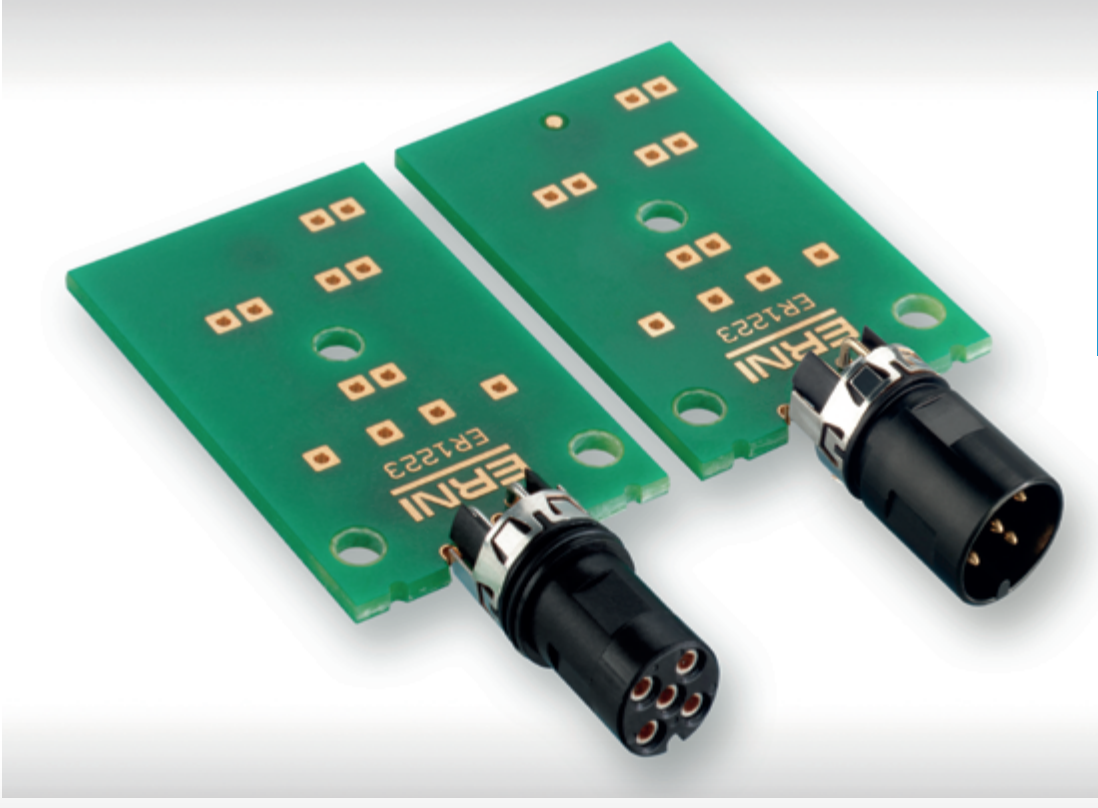

ERNI’s M8 and M12 connectors feature a black insulator is made of high-temperature plastic and is suitable for SMT soldering procedures. Designed for automated pick and place assembly and reflow solder processing, these connectors are available with A, B, D, and universal coding as well as 3, 4, 5, and 8 position sizes, coding dependent.

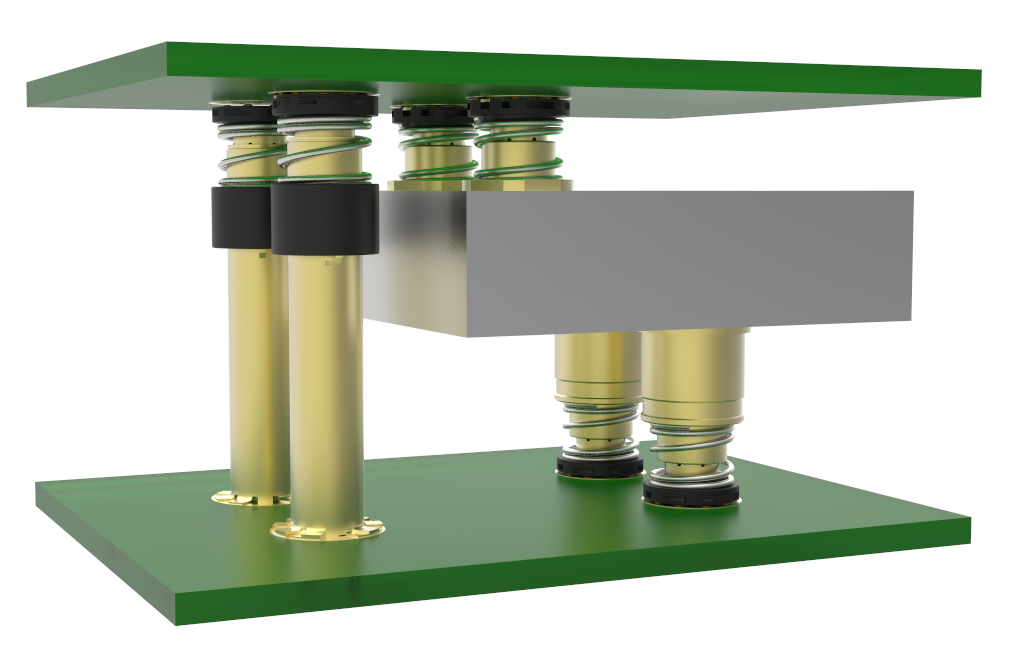

A wide variety of sensors are in common use today, including photoelectric, optical, magnetic, infrared (IR), ultrasonic, retroreflective, and accelerometers. The vast number of sensors found in high-volume or cost-sensitive applications, such as consumer and some commercial uses, are soldered directly to a PCB. Sensors may also be connected to discrete wire or cable that is terminated to a connector. This is especially common when the associated electronics are remotely located from the sensor, as in many industrial, automotive, and military and aerospace applications. Suitable connectors for sensing applications in these market sectors include circular connectors, such as an M8 or M12 type connector, as well as heavy duty rectangular connectors designed for automotive applications.

ERNI’s modular M8/M12 circular connectors are fully flexible PCB connectors offering IP65/67 protection for sensors requiring more signaling throughput in harsh environment applications. Used in a wide variety of applications such as vision systems, fill level, range, measuring, monitoring and pressure sensors as well as light barriers, position switches, field bus, and peripheral equipment, M8/M12 circular connectors meet international standards for low-voltage sensors/actuators and various field specifications.

Companies like Bulgin are developing sensor and connector solutions that can facilitate these rapidly evolving technologies. The company’s new M-Series is designed for manufacturing automation and industrial automation proximity sensing operations. The series was created to meet demand for a cost-effective and flexible solution for the implementation of the Industrial Internet of Things (IIoT).

Bulgin M-Series connectors are suitable for applications including factory automation, robotics, process control, medical, food and beverage processing and industrial networking.

In an interconnected world, each passive and active component must be selected with thought to its relationship with the other elements that make up the system in which it operates. Reliability is a key consideration. Choose carefully; the eyes and ears must be able to do their job well for the entire application to perform as expected.

Like this article? Check out our other IoT, 5G, and New Technology articles and our 2019 article archive.

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024