What are ECU Connectors?

Meet the Connector: ECU Connectors

ECU Connectors, also called PCM connectors, are used to connect different types of controllers, particularly in vehicle applications. An electronic control unit (ECU) or electronic control module (ECM) is an embedded system that controls one or more of the electrical systems or subsystems in a car or other vehicle. One side of the connector interfaces with the ECU (or BSI, UCH, EZS, CAS, counters, key loop, etc.) The other side connects to an OBD2 tool, such as Magpro2, Avdi, Smok, Bosch KTS, or Renault Clip. Modern motor vehicles can have up to 150 ECUs

A variety of specific connectors have been developed to interface with ECMs. These connectors feature attributes that serve the specific electronic system the ECM controls. These connectors are designed to handle the high-speed transmission and high voltage requirements needed to serve automotive applications. Rugged materials are selected for their ability to handle the overall harsh-environment conditions present in automotive environments.

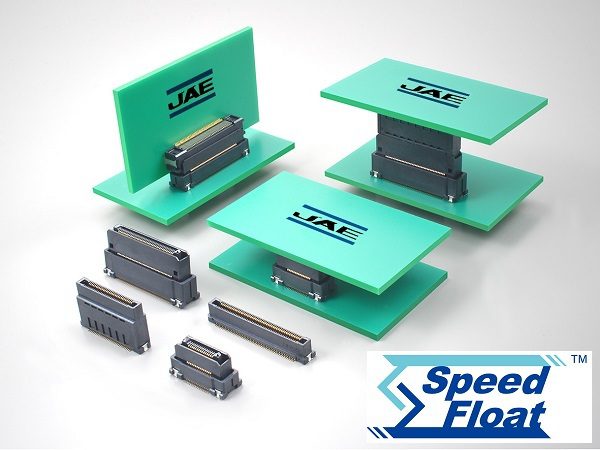

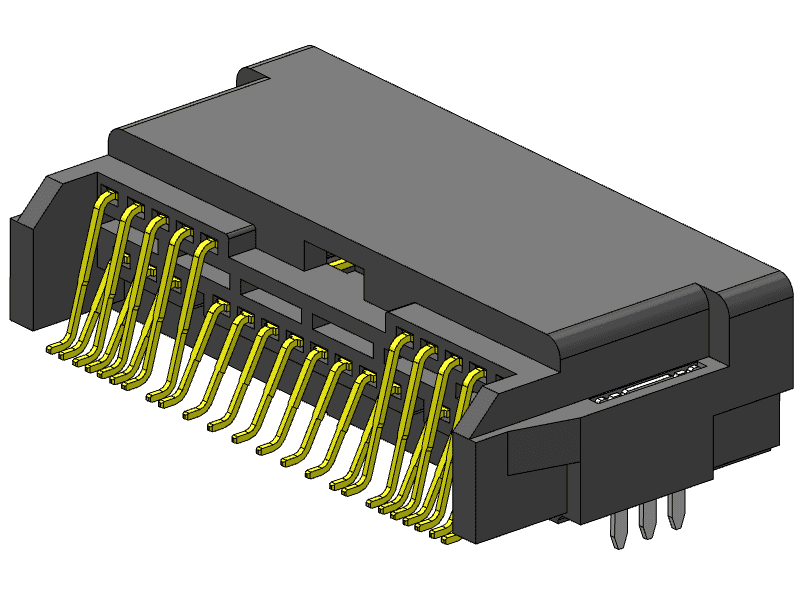

The MA01 Series from JAE features a highly reliable two-point contact structure, achieving high-speed transmission that exceeds 8 Gb/s. With an operation temperature range of -40 ℃ to 125 ℃ these floating-board connectors solve many of the issues found in ECU applications, such as misalignment during assembly, design limitations, and spacing constraints.

TE Connectivity’s 0.50 Connector Series is designed to support miniaturization and lightweighting trends in automotive applications, including electronic control units (ECU), body ECUs, navigation, power management, data communication modules, and other systems. TE’s 0.50 Connector Series is 47% smaller and 53% lighter than its 0.64 Connector Series, which helps engineers optimize design layouts and ECU utilization.

The series GZZD201 Low Profile BMS Connector from Greenconn offers reliable, compact solutions for automotive infotainment system needs. This low-profile board-to-board connector is an ideal option for the limited installation space found in automotive infotainment systems and ECUs.

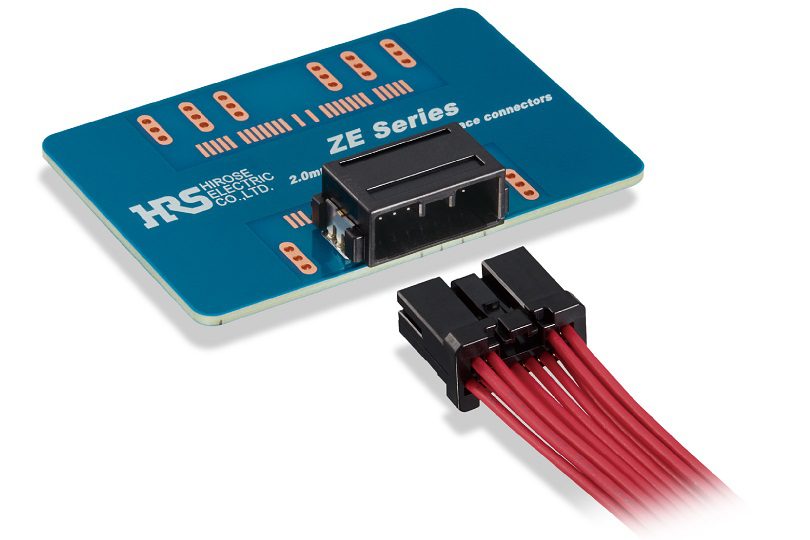

Hirose Electric’s low-profile wire-to-board ZE05 Series connector is designed for high heat and high vibration applications, including automotive converter, inverter, battery, on-board charger, ECU, and more. Rated to 5A @250 VAC, the mono-pole power connector is designed for a wide range of applications

Markets

- Automotive

- Transportation

- Industrial

Applications

In addition to supporting automotive ECUs, these connectors can also serve equipment used in factory automation, semiconductor manufacturing, office machines, measurements, and broadcasting.

Design Notes

- Many ECUs are used in modern automotive programs, including the engine control module (ECM), powertrain control module (PCM), transmission control module (TCM), brake control module (BCM or EBCM), central control module (CCM), central timing module (CTM), general electronic module (GEM), body control module (BCM), and suspension control module (SCM). ECU connectors link these electronic units within the overall wiring architecture.

- ECU connectors are designed to endure harsh, high-temperature, and high-vibration automotive environments. Rugged materials are selected that can endure extreme low and high temperatures (typically -40 °C to 125 °C).

- Very secure locking mechanisms, such as double locking designs, must also be designed to withstand shock and vibration.

- Size and weight savings continue to be imperatives in the automotive industry, making miniaturization an important consideration for most ECU connectors.

Suppliers

EDAC, Greenconn, Hirose Electric, ITT Cannon, JAE, Molex, Phoenix Contact, Positronic, TE Connectivity, Amphenol, Aptiv, C&K Switches, Kyocera AVX, Yamaichi Electronics

Related products

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for EDAC, Hirose Electric, ITT Cannon, Molex, Phoenix Contact, Positronic, and TE Connectivity.

Like this article? Check out our other Meet the Connector and Power articles, our Sensors and Antennas Market Page, and our 2023 and 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024