Three Key Considerations When Selecting EMI/RFI Shielding Solutions for Aerospace and Defense Applications

Proper shielding is necessary to protect mission-critical systems and components from interference in increasingly busy electronics environments.

By Lesa Smith, Marketing Communications Manager, and Neil Mahaffy, Senior Product Engineer, ITT Cannon EMI/RFI shielding

As aerospace and defense platforms and environments continue to evolve digitally, the proliferation of embedded electronics systems and portable electronic devices (PEDs), such as tablets and smartphones, is generating significant RF emissions that can negatively impact the performance of other electronic equipment.

These effects, known as electromagnetic interference (EMI) and radio frequency interference (RFI), increase the potential for signal and data corruption, crosstalk, and equipment malfunctions. In military applications, EMI/RFI can interfere with communication devices and radar signals, delay weapons systems deployment, and enable signal jamming, compromising missions and putting soldiers at risk. In commercial aviation applications, the proliferation of in-flight entertainment and connectivity (IFEC), in-flight wireless broadband connectivity, and fly-by-wire systems have increased both the complexity and density of cables, boxes, and connectors. If not properly shielded, these systems and components can generate stray signals that can potentially interfere with critical avionics, controls, air-to-ground communications, telemetry, and global positioning systems (GPS).

End-product environments are a significant factor in the shielding solutions selection process. Ensuring that signals in aerospace and defense applications are properly protected from EMI/RFI may require a series of solutions, including integrated EMI/RFI protection within the connector and external shielding materials designed to protect connectors and cable assemblies from EMI, as well as power surges and other harsh-environment conditions. While there is no one-size-fits-all solution, there are three key considerations when selecting high-performance interconnect shielding solutions and the partner who delivers them: experience in electronics and interconnect solutions, a comprehensive understanding of multiple shielding solutions, and demonstrated expertise in shielding and plating materials.

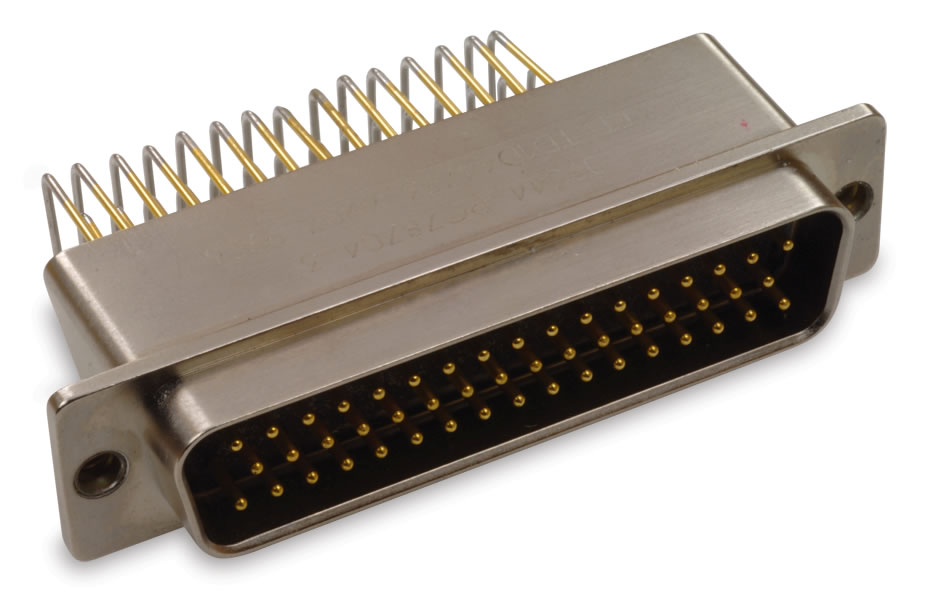

ITT Cannon’s TD1 Filtered D-Subminiature Connectors combine the functions of a standard electrical connector with a feed-through filter in a single, lightweight, and space-saving design that meets aerospace and defense industry demands for improved control of EMI/RFI.

1. Experience Matters

Regardless of the type of electronic device, proper protection must be applied to the vital components to achieve optimum performance. Devices that are employed in critical applications, such as military and aerospace systems, must meet more stringent reliability, durability, and performance specifications than their consumer counterparts. The first step to ensuring optimal connector shielding starts with selecting the right design and manufacturing partner. To help identify suppliers with the right combination of experience and capabilities, look for:

- Designers and engineers with both general electronics and interconnect-specific solutions experience.

- Aerospace and defense industry experience and a thorough understanding of its stringent reliability, durability, and performance standards and specifications.

- Proven knowledge of high-frequency, high-voltage, surge suppression, and filtering solutions.

- Experience in the design, testing, and qualification of highly engineered interconnect solutions.

- The right environment, equipment, and resources to perform the required testing.

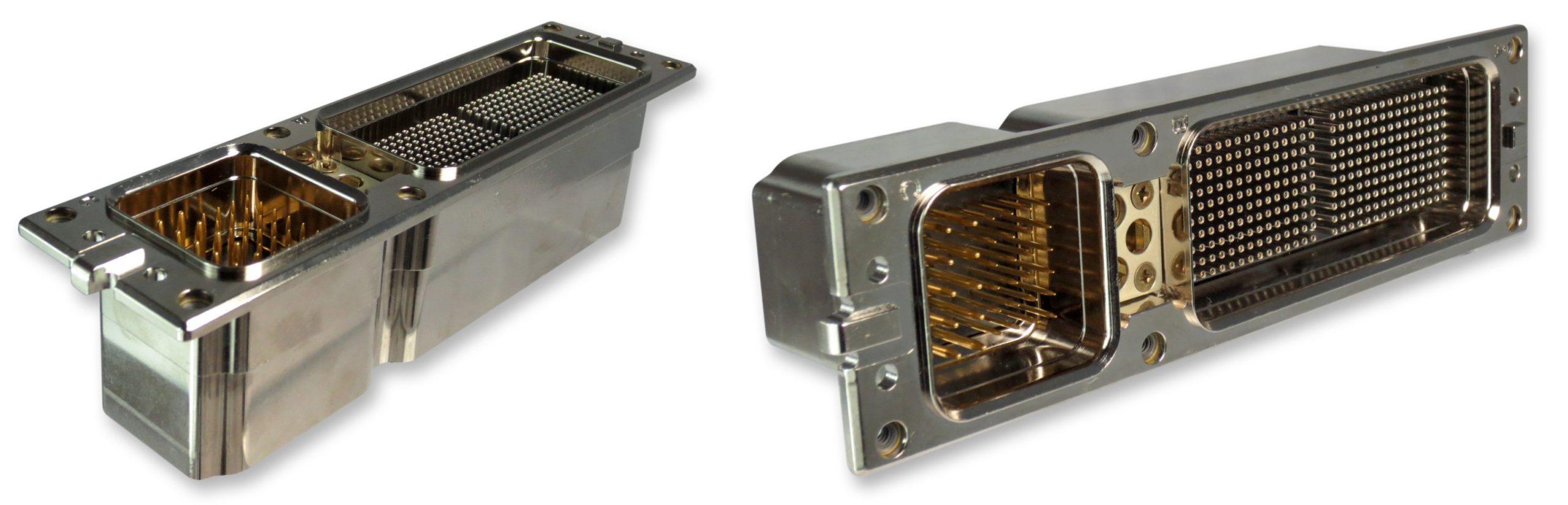

ITT Cannon’s high-density ARINC 600 TBKAD Filter Connector is an established standard for navigation and control system protection in the worldwide commercial aerospace industry. Available with up to 800 size 22 contacts in a single connector, they provide the highest density pinouts and deliver system-level EMI protection at the box interface.

2. Multiple EMI/RFI Shielding Solutions

Aerospace and defense system designers rely on connector manufacturers for high-performance, cost-effective EMI/RFI suppression solutions capable of solving complex EMI/RFI electronic issues. A number of proven, highly effective EMI/RFI shielding solutions ranging from external shielding materials to filtering at the connector interface are available, including filters, chip-on-flex technology, and cable assemblies.

Filters — Filtered connectors play a critical role in managing and suppressing EMI/RFI and surge spikes and supporting the proper performance of devices and equipment. Some connector designs provide standard filtering capabilities, including individual, isolated pin filtering for high-frequency noise, built-in ground plane barriers in the connector inserts, and filtering at the face of system boxes. A more effective connector signal barrier enhances these traditional filter attributes by offering system designers complete flexibility in defining or revising individual circuit capacitance, ground, and electromagnetic pulse (EMP) performance during the design and development phase. Many connector designs also incorporate shield cans on the PCB to protect the circuitry from signal interference. Connectors designed with proper shielding and EMI gaskets can typically satisfy EMI requirements. Electromagnetic interference can also be reduced by adjusting the capacitance value of a connector. Connectors with capacitance values up to 50,000pF can significantly reduce the signal noise traveling through a device to help improve overall system performance.

ITT Cannon’s KJ 38999-Style Chip-on-Flex (CoF) Connector protects critical circuits from electrical interference by providing a stray signal barrier upstream and away from electronic devices without impacting system performance.

Chip-on-Flex Technology — Fragile ceramic-planar-array block capacitors have been replaced with state-of-the-art flexible circuits in applications that require the utmost protection, such as mission-critical military and aerospace systems. Chip-on-flex (CoF) technology is suitable for applications that require lower working voltages, typically below 200VDC for high-frequency filtering and below 100VDC for low-frequency filtering, and its frequency rejection response is most effective to 200MHz. Designed to increase durability and reliability in harsh-environment applications, these circuits are comprised of individual chip capacitors that are surface-mounted on a pad adjacent to (but not soldered to) the feed-through contacts and can help relieve the stress at certain points that are vulnerable to thermal shock and vibration for up to 1,000 cycles. CoF filter connectors use off-the-shelf chip capacitors mounted on the flex circuits for filtering. This type of filter connector has standard filtering capabilities that include filtering at the face of system boxes, plane barriers in connectors, and high-frequency noise. Chip-on flex technology also allows engineers to package capacitors for filtering, as well as diodes and metal oxide varistors (MOVs) for transient voltage surge (TVS) protection, within a single connector housing, resulting in a very compact and lightweight high-performance design.

Cable Assemblies — High-performance, bonded cable assemblies at the cable interface offer another line of defense against EMI/RFI. Sealing connector shells and using cables with high shield coverage that allows for up to 80dB of attenuation offers excellent protection from EMI. Cables with high shield coverage and special overmold features provide very robust, yet cost-effective solutions for protecting against RF emissions. The two most common shields used in cable assemblies are foil wraps and metal braids. Metal braids are often made of tin, silver, or nickel over copper, but special braids for applications that require non-magnetic material, such as radar applications, are also available and can be made from materials including tin/copper alloys with an iron core (SnCuFe).

3. Materials and Plating

The most effective defense against EMI/RFI is filtering at the connector interface, with shielding materials as the next level of signal integrity. Experienced interconnect solutions engineers and designers frequently recommend the use of multiple shielding solutions for more complex needs and custom or especially sensitive applications.

Shielding materials include acrylic-based sprays, paints, or brush-on coatings applied to electronic housings. These shields contain extremely pure metals, such as copper, silver, and nickel, to help reduce or eliminate the effects of EMI/RFI. Different materials help shield critical interconnects in different ways. For example, soldier-worn connectors must be designed with features that allow for termination with 360° shielding, including banding platforms, cable banding platforms, EMI springs, and conductive O-rings.

Connector plating materials can provide additional protection against EMI/RFI as well. Plating is available in a variety of materials with unique characteristics capable of meeting a wide range of application- and environment-specific demands. For example, black zinc nickel finish is a cost-effective, sustainable, and RoHS-compliant plating alternative to cadmium, the use of which is strictly limited to an ever-narrowing range of special circumstances due to its toxicity. Black zinc nickel plating provides long-lasting corrosion resistance to exposed connector surfaces used on military and commercial aircraft. It is also military-qualified and conductive for EMI shielding, making it a suitable choice for harsh-environment communications applications.

Summary

EMI/RFI will continue to be a challenge due to the high density of electronics systems in nearly every aspect of modern life, but the right combination of experienced interconnect engineers, systems designers, advanced materials, and innovative designs can provide reliable EMI/RFI protection in even the noisiest and harshest environments.

For more information, visit ITT Cannon online.