The AI Impact: Artificial Intelligence Influences Connector Development

AI technologies are being used to help analyze rapidly growing data sets, which is generating substantially more data and further increasing demand for ever more powerful connectors.

Artificial intelligence has become a prominent element in many advanced system designs, including leading sensing and analysis tools used by data centers and military agencies. Though AI is a high-level software technology, it’s having a major impact on the development of electronics, including connector designs that can accommodate the dramatic increase in the volumes of data that pass between data centers and vehicles, businesses, government facilities, and the many other elements of our increasingly “smart” environment that utilize connected technologies.

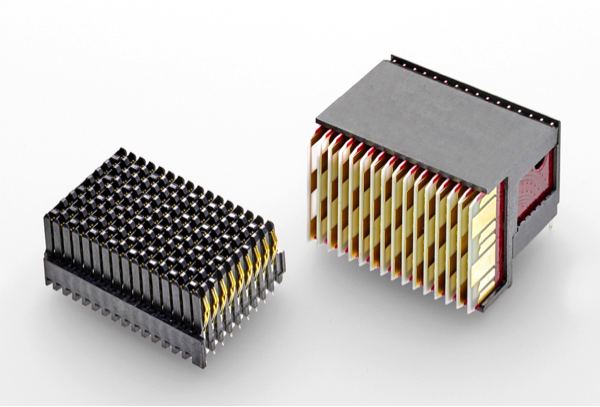

“From a connector standpoint, AI uses multi-GPU solutions, which drives speed all across the network,” said Matthew Burns, product marketing manager at Samtec. “Emerging customers are using AI to get into new markets, and OEMs are expanding their use of AI. Beyond military applications, anything going on in data centers is tied to AI.”

Samtec expects AI to dramatically increase data transfer volumes and speeds, sparking changes in system design and components.

Burns recently discussed AI technology at the 2019 Embedded Tech Trends conference, where VITA members and military technologists discussed trends in the boards and module technologies. In addition to military usage, products based on VITA standards are used in transportation and industrial applications. Many speakers at the conference said they expect machine learning to be used in close conjunction with data gathered by sensors like cameras and radar. Sensors are moving to higher resolutions, which increases the volume of data. That can make it harder for humans to analyze massive images. It can also push the limits of connector technologies.

“AI drives speed requirements and density,” said Mark Benton, active product manager at TE Connectivity. “When you go to high definition streaming, a 4K signal equals a 12Gb/s raw data rate. The military doesn’t want to use compression. If you’ve got to process four HD data streams, you have to move a lot of data through the connectors.”

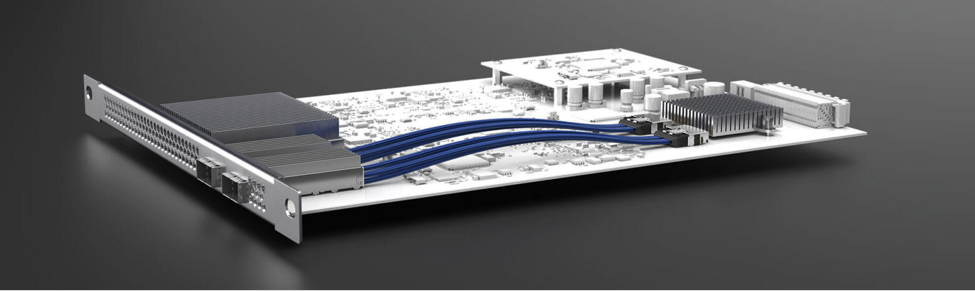

TE Connectivity’s MULTIGIG line for rugged embedded computing helps engineers work with high-resolution sensors.

Though many observers predict that AI’s usage will increase data flow, that won’t happen in all systems. Some system designers will adopt a distributed architecture, putting intelligence in sensors. Processors on the sensor can do preliminary data analysis, determining which segments of the imagery might need further scrutiny. Only these images will be transferred to the central computer.

“AI can reduce data transfer and data storage requirements by transferring only data that requires attention or action,” said Emil Kheyfets, military product line director at AiTech Defense Systems. “That can save hundreds of gigabytes per camera over the course of a mission.”

Regardless of where processors are located, AI will require high bandwidth. The large volumes of data created by sensors will often need to be analyzed immediately. The processors that analyze copious amounts of data run at extremely high speeds, so a lot of data will be flowing from sensors to memories and processors. That’s changing board–level designs.

AiTech modules may be designed with distributed intelligence to reduce data transfer requirements.

The FR4 material used to build nearly all printed circuit boards (PCBs) over the past several decades can’t handle some of the high-speed signals that are carried through advanced systems. That’s prompting a growing number of design teams to turn to so-called flyover technologies, in which fast signals are routed over wires instead of traces on the PCB.

“AI and machine learning are fueling growth,” said Burrell Best, signal integrity architect at Samtec. “AI requires a lot of computing power, which is being met by FPGAs and graphical processing units. Faster systems require advanced fabrics and attached storage. As we get down the road with faster fabrics, signal integrity really matters. As FR4 becomes prohibitive, cabling is trending towards ultra-thin gauge cables and low–loss dielectrics, which provide superior signal integrity performance over printed circuit board materials.”

AI’s impact is being felt far beyond boards and modules. Connector makers and other manufacturing and industrial environments are starting to use AI to analyze their operations. That could lead to significant changes in many different areas.

“Samtec is investing in using AI to streamline manufacturing processes,” Burns said. “As we grow our product families, our supply chain is getting wider. We’re using AI to try to figure out how to streamline the supply chain.”

In a connected world, AI will touch every aspect of the electronics supply chain, from the individual components that are the building blocks of these systems to the functionality that will ultimately change every aspect of industry and society.

Like this article? Check out our other datacom/telecom, sensor, and new technology articles and our 2019 article archive.

- State of the Industry: 2022-2023 Connector Sales - April 16, 2024

- Amphenol is On a Roll - April 2, 2024

- Nicomatic Proves That Two Heads are Better Than One - March 26, 2024