Tesla’s NACS Connector Poised to Standardize U.S. EV Charging Landscape

The interface is now leading a global field of competitors, simplifying the EV charging process and bringing a future single standard into focus.

U.S. automakers Ford and General Motors will adopt Tesla’s North American Charging Standard (NACS) charging connector as the interface of choice for their upcoming EV models. In the days following GM’s June 2023 announcement, a sizable number of charging station companies, including Tritium, and other automakers, including Volvo, Rivian, and Mercedes-Benz, quickly announced intentions to follow suit. Hyundai is studying the possibility of making the change as well. This changeover will have the effect of making the Tesla connector the de facto EV charging standard in North America and beyond. Currently, many connector companies offer multiple interfaces, meeting the needs of diverse automaker OEMs and regional markets.

“We are very surprised about the dynamics of the NACS discussion of the past days,” said Michael Heinemann, CEO Phoenix Contact E-Mobility GmbH. “As a pioneer of fast-charging technology, we will of course follow the decision of our global customers. We will provide high-performance solutions on the vehicle and infrastructure side for NACS. Shortly, we will present a timeline and samples.”

Tesla’s NACS connector

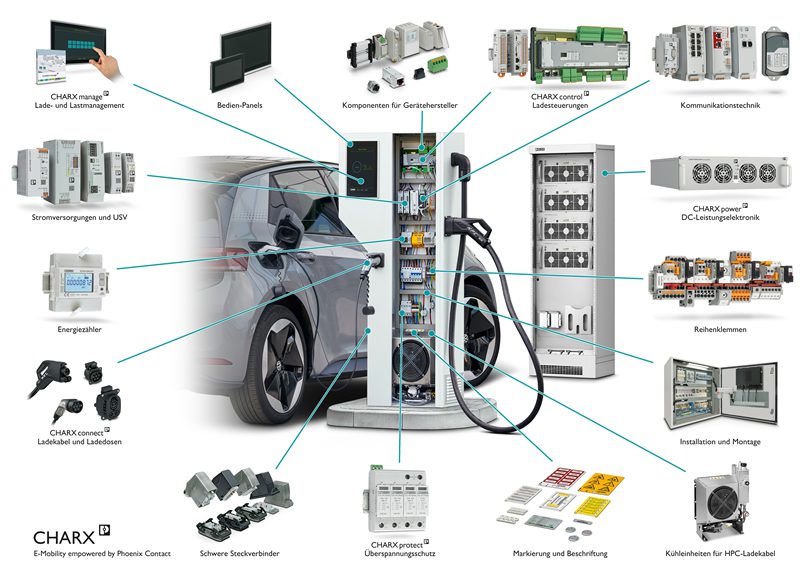

CHARX EV charger solutions from Phoenix Contact

One complicating factor along the way to the widespread adoption of electric vehicles has been the lack of a unified charging connector. Just as the adoption of the Type-C USB connector has simplified the future of device charging, a universal interface for car charging will enable seamless vehicle charging. Right now, EV owners must plan charging to occur at specific charging stations or use an adaptor to charge at non-compatible stations. In the future, using the Tesla NACS standard, drivers of all EVs will be able to charge at every station along their journey without using an adaptor. Older EVs and other types of charging ports will be able to connect using Tesla’s Magic Dock adapter. However, NACS is not used in Europe. “Not even by Tesla,” said Heinemann. “The charging infrastructure in Europe uses the CCS T2 standard. Tesla charging stations can also be used to charge with either the CCS T2 or the European Tesla connector.”

The current charging scene

A selection of EV charging connectors are currently in use, varying by region and automaker. Cars that are designed for AC charging use Type 1 and Type 2 plugs. Type 1 includes the SAE J1772 (J plug). It has a charging speed of up to 7.4 kW. Type 2 includes the Mennekes or IEC 62196 standard for European and Asian vehicles (manufactured in 2018 forward) and is known as SAE J3068 in North America. It is a triple-phase plug and can charge up to 43 kW.

ITT Cannon’s ECCV Electric Vehicle Charging Connector, designed for the European market, is an IEC (Type 2) vehicle coupler solution that provides low contact resistance and a minimum of 10,000 mating cycles. It is available for single and three phase charging systems and has a current rating up to 63A.

For faster DC charging, the Combined Charging System, or CCS, is used. This interface adds two high-speed DC fast charging pins to the J1722 Type 1 plug. The CCS2 version is widely used in Australia. The CCS connectors deliver 500 amps and 1000 volts DC at 350 kilowatts (kW).

The Guobiao standard GB/T 20234.2-2015, used in Chinese EVs, is another EV charging connector and it is available in both AC and DC configurations. In Japan, the near-legacy CHAdeMo connector is still used.

“Phoenix Contact has offered products for charging infrastructure as well as the vehicle interface for more than 10 years, including products, systems, and solutions for CCS T1 for the North American market, CCS T2 for the European market, and GB/T for the Chinese market,” said Heinemann. “For all markets, we are offering products for AC and DC charging up to cooled systems with up to 500 kW. We have just developed a 500 kW HPC connector for CCS Type 1. This is currently in very high demand in North America and also, for example, in Korea.”

Phoenix Contact’s GB/T EV charging connector serves the Chinese EV market, the world’s largest.

Tesla NACS advantages

Tesla made the NACS design and specification files available to other automakers in November 2022, saying the Tesla NACS plug is “the most proven in North America, offering AC charging and up to 1 MW DC charging in one slim package. It has no moving parts, is half the size, and is twice as powerful as CCS connectors.” The NACS uses a five-pin layout. The same two primary pins are used for both AC charging and DC fast charging. The other three pins provide similar functionality to the three pins found in the SAE J1772 connector. Some users find the NACS design easier to use.

Access to charging stations is a key advantage. Tesla’s Supercharger network is the largest and most established EV charging network in the world, with more than 45,000 stations capable of adding a 322-miles charge in less than 15 minutes. Opening this network to other vehicles makes EV charging more convenient closer to home as well as on journeys along longer routes.

“E-mobility will continue to develop and penetrate all vehicle sectors, ” said Heinemann. “Particularly in the utility vehicle sector, in the agricultural industry and for heavy construction machinery, significantly higher charging powers will be required than today. This will require the establishment of additional charging standards, such as the MCS (Megawatt Charging System), which takes these new requirements into account.”

Continuing refinement

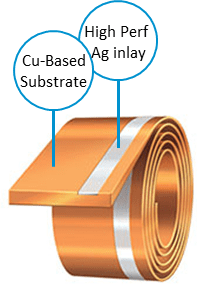

The selection of dominate charging interface does not mean the NACS connector technology is settled. Interconnect companies continue to refine elements of the design, including material advancements. Materion Corporation has spent decades engineering advanced materials that enable safer and more reliable lithium-ion packs, high-performing chargers, lightweight battery enclosures, and other solutions for EV batteries and charging technologies. The company’s iON EV™ clad is a silver-based alloy specifically designed for its low insertion friction/force, outstanding wear characteristics, and high electrical conductivity. It was engineered as a drop-in replacement for pure silver that offers improved performance and the durability to withstand the high energy environment of fast charge connectors. Improvements such as these mean that the NACS interface in current use will continue to evolve.

“Optimizing EV performance demands innovative materials that address the unique challenges of automobile electrification,” said John Nickel, Materion’s Senior Manager of Product Development. “By choosing next-generation materials for EV components, manufacturers can continue to evolve their products to enable new technology.”

Innovative alloy products like this copper-based substrate from Materion Corporation improve the conductivity of charging connectors.

The emerging dominance of the NACS interface is a significant development in the evolution of automotive technologies. Connector Supplier will continue to cover EV charging as this technology continues to evolve.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for ITT Cannon, Materion, and Phoenix Contact.

Like this article? Check out our other articles on Standards and Technology Trends our Automotive Market Page, and our 2023 and 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024