Terminal Blocks for Heavy Duty Applications

Terminal blocks are a simple, inexpensive, and useful type of connector. They are a good choice for simple circuits and have a long history of use in transportation and industrial equipment.

Terminal blocks or terminal connectors are a simple, useful, cost-effective, and often crucial component in transportation applications. You need to know a few things about these unique connectivity solutions to know if they are the right choice for your wiring design.

Terminal blocks are also called screw terminals or barrier strips. They are essentially an interchange that joins two or more wires together and distributes power throughout an application. They function as a simple but powerful connector, in many instances bringing together wires without the use of solder or other interconnects. They have long had utility in demanding applications such as fleet vehicles, automobiles, or heavy machinery, where they are often used to connect to switch panel outputs.

Terminal blocks are often used in vehicle control panels and behind vehicle dashboards. They usually handle higher levels of voltage than other types of connectors. Think of a terminal block as a hub that stores ground and power in one place.

This type of connector is not used much in electric vehicles. Busbars, in contrast, are used to transfer high current loads, such as those that might be seen in EV battery pack applications. There is some momentum for using terminal blocks in electric vehicle charging stations.

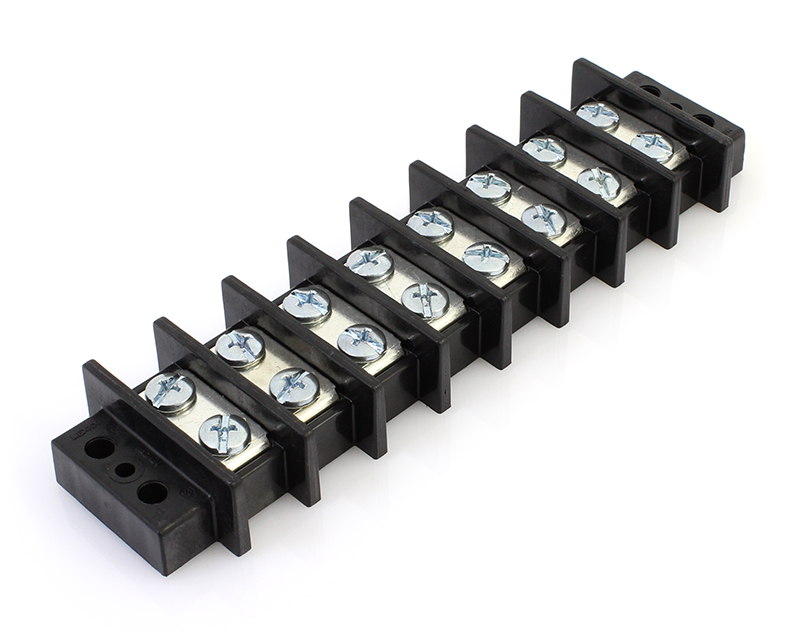

Eaton’s Bussman Series double-row terminal blocks, available from Waytek, are general-purpose, panel-mount terminal blocks suitable for use in a variety of electronic and electrical applications and designs.

Terminal blocks serve as a sort of routing tool for wiring purposes. Just like a truck driver takes a cloverleaf interchange to exit an interstate and get onto the next one, a terminal block serves as a conduit through which different circuits connect to each other. Terminal blocks protect and insulate exposed wire and cable ends and also serve as a clamping system, attaching wiring to the interior body of a vehicle or equipment. Busbars, which are essentially flat bars of conductive metal, are more commonly used with high-gauge wires to distribute power.

Eaton Bussman double-row terminal blocks come in a variety of sizes with two to 12 positions. This eight-position model, available from Waytek, can accept wire gauges ranging from 22–8AWG and is rated for 30A and 600V.

Attaching a Terminal Block

Terminal blocks are designed for quick and simple connections. Most commonly, you connect a wire to a terminal block by stripping it of insulation, wrapping it around a screw, and then securing the screw within the terminal. Terminal blocks may also feature input and output openings into which wires can be inserted and then clamped down inside the block. Another option is to solder or crimp a connector to the wire and attach the connector to a terminal block that can receive connectors. In transportation applications, you typically see the latter option; although screw connections may still be present in some non-essential devices.

Generally, terminal blocks serve two main purposes: They are used to connect different circuits together and to provide an electrical ground for the circuit. Grounding, of course, provides a safe route for a circuit to terminate, reducing the risk of short circuits within your system and the risk of serious injury to members of your team. Connecting different circuits can be a time-consuming task that terminal blocks make easier. Although, for circuits that need to operate under high power or high vibration conditions, installers may need to use different types of products, such as busbars, junction blocks, and power splitters.

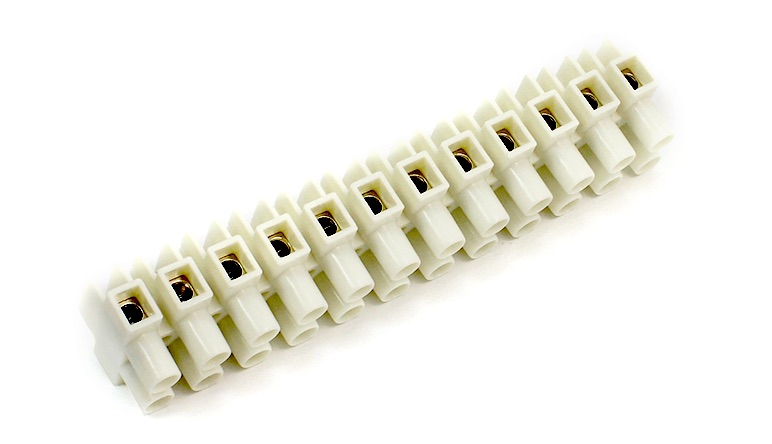

Molex terminal strips, available from Waytek, can be panel-mounted or free-hanging and although they come with 12 poles, they can easily be cut down to three, six, or nine poles, as needed. Most applications only require three poles: load, neutral, and ground.

Terminal Blocks Offer Advantages and Disadvantages

The main advantage terminal blocks offer is cost savings. Compared to other types of connectors, terminal blocks are relatively cheap. They’re also, to some degree, a time-saver, as connecting wires to one isn’t an elaborate process and it can be easily done by any well-equipped shop. If a driver/operator is properly trained and has the correct tools, small repairs to in-cab equipment can even be made on the road, if policy allows it.

The main disadvantage, on the other hand, is that in the presence of vibration or jostling, even well-secured wires can be knocked loose from terminal blocks. Therefore, it is critical to test connections before implementing them to ensure that they can withstand the rigors they’ll face in heavy-duty operating environments. In addition, terminal blocks typically don’t come with covers and aren’t sealed against the elements, which limits their suitability to interior applications or requires them to be installed in sealed control panels or containment units (e.g., inside a locker on a work truck).

When choosing terminal blocks, it’s important to consult with your team about their application needs and concerns, as most terminal blocks are optimized for a specific purpose. They’re also not the ideal solution for all connectivity situations, but for quick, efficient connections and power distribution, terminal blocks are handy to have.

Like this article? Check out our other power and terminal blocks articles, our Transportation and Industrial Market Pages, and our 2021 and 2020 Article Archives.

- Hybrid Connectors for Heavy-Duty Transportation - August 23, 2022

- CAN bus Connector and Cable Considerations - February 15, 2022

- Heavy-Duty Connectors for Off-Highway Applications - May 4, 2021