SWaP-Optimized Rectangular Connectors for Harsh-Environment Mil/Aero Connectivity

Rectangular connectors offer significant size and weight reductions, effective EMI protection, and meet military and aerospace qualifications. They offer valuable cost and performance benefits compared to traditional circular connectors.

Connectivity solutions for military and aerospace projects often need to be optimized for size, weight, and power (SWaP) to satisfy the stringent physical and performance requirements for the equipment used in these high reliability markets. Rectangular composite connectors with EMI protection can strike the right balance.

Rectangular Connectors

Circular connectors have a long history in military and industrial applications. However, rectangular connectors now dominate in modular machine designs and factory automation, robotics, and power generation equipment where circular connectors were once unchallenged. In many applications, the advantages of rectangular connectors supersede those of circular connectors, particularly in terms of cost, size, and weight per circuit, design flexibility, and ease of handling.

For example, the per-unit cost of circular connectors and their harnessing (on a per-circuit basis) tend to be higher than those for rectangular connectors. In addition, the cost of replacing or adapting circular connectors is often higher because circular inserts aren’t always as easily interchangeable as rectangular ones. Rectangular connectors have increasingly been designed to utilize readily interchangeable inserts — including those from other manufacturers — to support future-proofing and long-term cost effectiveness as technology progresses.

Although a circular connector generally isn’t larger than its rectangular counterpart, circular connectors require more space around them for fastening than rectangular connectors, which can be stacked close together and affixed with external hardware to ensure stability in harsh environments. Rectangular connectors can also be ganged together to combine shells for additional space savings and tend to require less customization for PCB mounting, especially in right-angle and surface-mount configurations.

This exploded view of Cinch Connectivity Solutions’ C-ENX Connector includes separate locking hardware and interchangeable inserts that accurately position the contacts to prevent electrical shorts and seal against dust, moisture, and corrosive fluids.

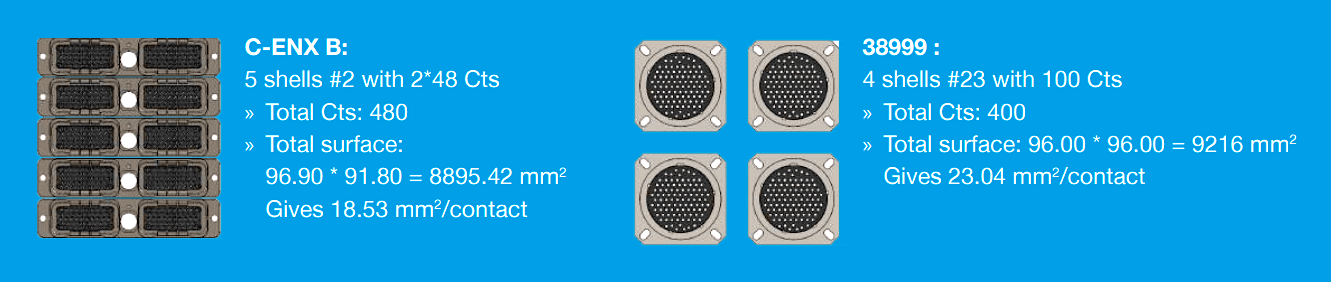

Rectangular connectors, like the C-ENX Series, can conserve space compared to circular connectors, such as 38999-style connectors.

Another advantage is that rectangular connectors are more obviously keyed than circular connectors, which increases ease of installation, prevents damage during installation, improves the wire routing process, and mitigates the strain cables can put on connectors.

Rectangular connectors also improve rack and panel designs, which rely on blind mating, and thus requires tighter tolerances for pin positions. Rectangular designs control tolerance in the X and Y directions and don’t have to account for the additional twist tolerance found in circular designs. Plus, the rack and panel designs they enable support the quick swap-out of entire panels, which helps reduce equipment downtime.

Since every ounce of weight can amount to more than $1,000 in aerospace operating costs, rectangular connectors are attractive alternatives to circular connectors in applications that prioritize SWaP-C (size, weight, power, and cost) optimization.

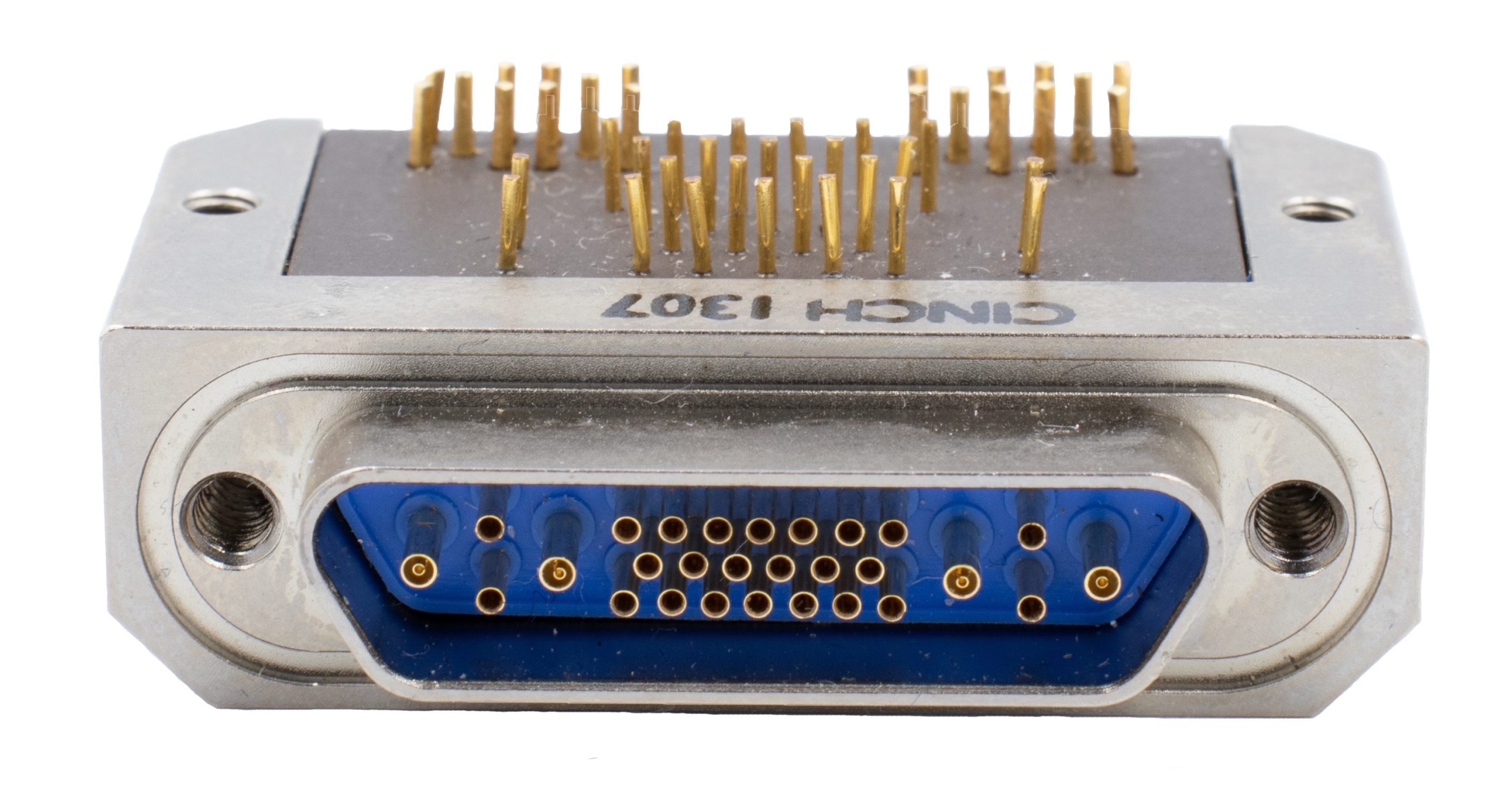

This hybrid rectangular connector from Cinch Connectivity Solutions’ Dura-Con line has a right-angle orientation, four RF contacts, 24 signal contacts, and surface-mount terminations and is ideal for use in applications that require both power and signal connections.

Composite Shells

Composite shells are polymer structures with ceramic filler and are much lighter than even lightweight aluminum shells. They are typically much less expensive than aluminum and other metal shells because they tend to be molded, which is a much faster process than the machining required to create metal shells.

Nickel plating provides effective shielding for composite connectors, protecting internal circuits from lighting strikes and electronic noise. This material has made the comparative performance of composite and metal shell connectors closer than ever.

Aerospace standards such as ARINC 800, EN4165, and EN4644, include specific requirements for composite shells. Cinch Connectivity Solutions’ C-ENX and C-DMX product lines offer many composite-shell solutions, including the C-DMX single-bay cable assemblies with nickel-plated composite shells and 16-02 inserts (pictured here).

EMI Protection

Circuit pathways are required to run very close together, especially in space-constrained aerospace equipment. In many such applications, power circuits tend to run right next to sensitive signal circuits. This arrangement can lead to signal integrity problems in the circuits, especially in applications with a high risk of electronic interference like military aircraft, which could be targeted by enemies’ electronic signal-jamming equipment. In these harsh environments, EMI shielding can be added for protection.

EMI shielding basically amounts to installing Faraday cages around sensitive signal pathways and can be achieved using metal braided sleeves or foil. Braided metal sleeves are more common in aerospace applications due to its improved durability over foil and its additional surface area, which helps dissipate high-frequency noise to the outer surface. The braided sleeves should be affixed to connectors in a way that completely encompasses the pathway in order to provide effective 360° EMI protection. These connections are often made by encapsulating the braided sleeve within a metallized epoxy or mechanically fixing it to the connector with a metal strap. In addition, the connectors they affix to need to be highly conductive with outer pathways that exhibit low resistance across the mated pair.

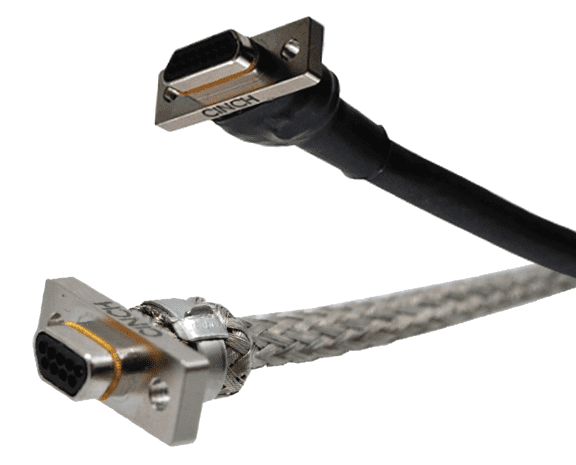

Cinch Connectivity Solutions’ Dura-Con Micro-D cable assemblies designed in accordance with MIL-DTL-83513 specifications feature compressible EMI gaskets and braided metal sleeves along the circuit pathway.

Rectangular connectors with lightweight composite shells, effective EMI protection, and appropriate military and aerospace qualifications can offer significant size and weight reductions, as well as cost and performance improvements, compared to traditional circular connector solutions.

For more information, visit Cinch Connectivity Solutions online.

Visit Times Microwave to learn more.

Like this article? Check out our other Harsh Environment and High-Reliability articles, our Mil/Aero Market Page articles, and 2021 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- How to Select Electrical Connectors for LEO Satellites - April 9, 2024

- SWaP-Optimized Rectangular Connectors for Harsh-Environment Mil/Aero Connectivity - November 16, 2021