SOSA Standards to Embedded Systems Development

Updated: January 2023

The Sensor Open Systems Architecture (SOSA) Consortium has created an agile, modular, open reference standard for designers of sensor-rich military and commercial applications as they integrate these powerful connectivity components into new embedded designs.

Compliance testing is now underway on connectivity products that support embedded computing systems in military and aerospace applications in accordance with the new SOSA technical standard. Released in September 2021 by the Sensor Open Systems Architecture (SOSA) Consortium, Technical Standard for SOSA Reference Architecture, Edition 1.0 offers immediate guidance on system, software, hardware, and best practices for electrical and mechanical engineering of systems that align with Modular Open Systems Approach (MOSA) principles. MOSA provides an acquisition and design strategy to help designers adopt open standards through the use of scalable designs that integrate upgradable modules. The result is reduced costs and extended product lifetimes.

SOSA, an Open Group collaboration between the U.S. military branches, the electronics industry, and academia, puts sensor technologies in the focus. By identifying hardware and software solutions that can support the demanding data and processing requirements of sensor-rich architectures, the consortium helps engineers specify components that serve the growing sensor needs for military and aerospace applications. In addition to meeting Department of Defense (DoD) objectives, this initiative serves the Command, Control, Communications, Computers, Intelligence, Surveillance and Reconnaissance (C4ISR) community, as well as vehicle integration for C4ISR/EW Interoperability (VICTORY) and other transport, radar, weapons, and autonomous aircraft programs. Ultimately, use of SOSA-aligned components will accelerate time to market for new products and facilitate upgrades of existing systems.

Components suppliers, along with IBM, Intel, Philips, and other member companies, have been instrumental in the development of this standard. AirBorn, ITT Cannon, Radiall, Samtec, Smiths Interconnect, SV Microwave, TE Connectivity, and other suppliers of rugged and high-reliability interconnect products for embedded systems joined the consortium to influence the development of powerful, cost-effective options. The consortium identified parameters and products that enable designers of military applications and upgrades to specify within an interoperable range of solutions. A range of existing and new products relevant to the SOSA standard, including backplanes, connectors, power supplies, and I/O interfaces, are available now and currently labelled as SOSA-adjacent.

Mouser Electronics stocks Huber + Suhner’s new SOSA-standardized RF cable assemblies (size 16 SMPS socket to socket.)

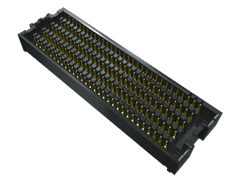

Many applicable products have been available for years as commercial- off-the-shelf (COTS) options but they are now reaching new markets due to their versatility in open systems designs. Samtec’s SEARAY line of high-speed, high-density open-pin-field arrays is one such SOSA-aligned solution that has a history in telecom, datacom, computers and peripherals, industrial, medical, test and instrumentation, AI, and machine learning applications.

“Within the military world, they are used in radar, communications, drone/UAV, SATCOM, avionics, and weapons/munitions, among others,” said Danny Boesing, product marketing director at Samtec. “They are popular because they have an open pin field design, which allows engineers/designers to create their own power/signal/ground pinouts. They come in a wide variety of pins per row, number of rows, and stack heights, and they’re simply rugged.”

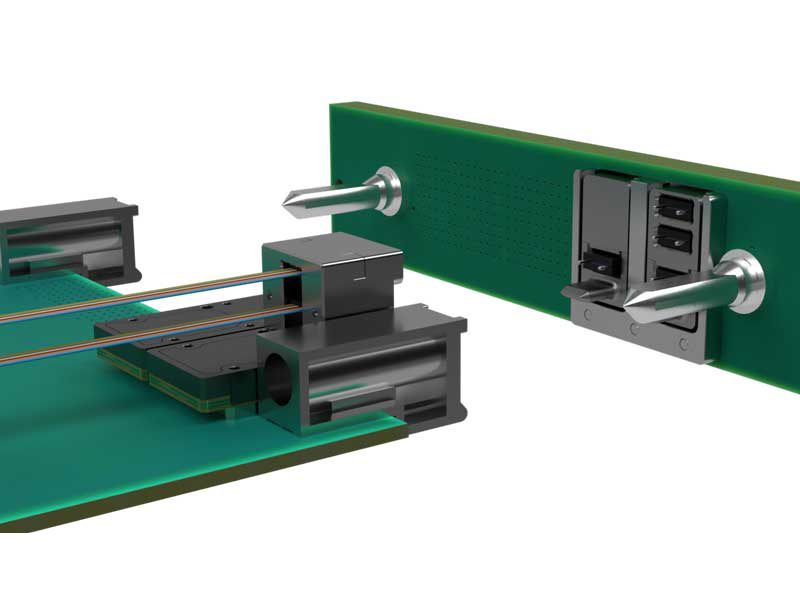

Smiths Interconnect’s LightCONEX® optical plug-in and backplane module connectors for VPN systems serve SOSA’s size, weight, and power goals and include a fixed, plug-in module connector and a floating backplane connector compatible with proposed VITA 66.5 standard.

New products specifically designed to meet the parameters of SOSA include Smiths Interconnect’s LightCONEX optical plug-in and backplane module connectors. These connectors are compatible with the VITA 66.5 draft standard and align with the SOSA Technical Standard for VPX systems. LightCONEX is the sum of two elements: a plug-in and a new backplane connector. The plug-in modules are modified versions of Smiths’ LightABLE mid-board transceivers; shrouds were added to enable the backplane connectivity, said Jon Lundberg, product line manager, Smiths Interconnect. “While initially focused on the mil/aero market, any platform that is space-constrained, has huge data throughput requirements, and operates in a rugged environment could benefit from this technology.”

“Smiths has been instrumental in helping draft the VITA 66.5 standard, which is very close to being released for public review. SOSA, on the other hand, is a consortium that looks more at the system level and it adopts several of the VITA backplane profiles,” said Lundberg. “We are also SOSA members and involved in a couple of the subcommittees.”

Samtec’s SEARAY® open-pin-field array meets SOSA requirements and support 56 Gb/s PAM4 applications.

Parameters influencing the design of these products align with the overall size, weight, and power (SWaP) imperatives that have been guiding military application design for years. Small-form factors are critical, yet products must also deliver high-speed performance, support high-density configurations, and provide high reliability in challenging operating environments on the ground as well as in airborne technologies. Ruggedness against shock, vibration, temperature swings, ingress, and other situational elements is critical for electronics deployed by the military.

Products that align with the SOSA standard may also be approved for other military standards, including VITA standards, specifically VITA 42, VITA 57.1, VITA 57.4, VITA 74, and VITA 88.

“SOSA uses OpenVPX architecture inside the box (leveraging VITA standards), and will use M38999 and other rugged I/O interconnects at the panel. And where a new technology or standard was needed for implementation in SOSA aligned systems, SOSA drove that back to VITA for standardization (examples are RF/optical connector module configurations, high density optical VITA 87, and new VPX slot profiles in VITA 65). SOSA actually takes a subset of the interconnect and hardware architecture standards in VITA to define standard use cases for sensor systems and driving commonality that will be followed for next-generation systems,” said Michael Walmsley, TE’s global product manager in the Aerospace, Defense, and Marine business unit.

At the conclusion of the testing process, products will be identified as SOSA-compliant. Products will be deployed across the U.S. military branches in OpenVPX architectures.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for AirBorn, ITT Cannon, Mouser Electronics, Samtec Inc., Radiall, Smiths Interconnect, SV Microwave, and TE Connectivity.

Like this article? Check out our other articles on Standards, Mil-Spec connectors, and Ruggedized connectors, and additional coverage of Sensors & Antennas and Mil/Aero Markets, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024